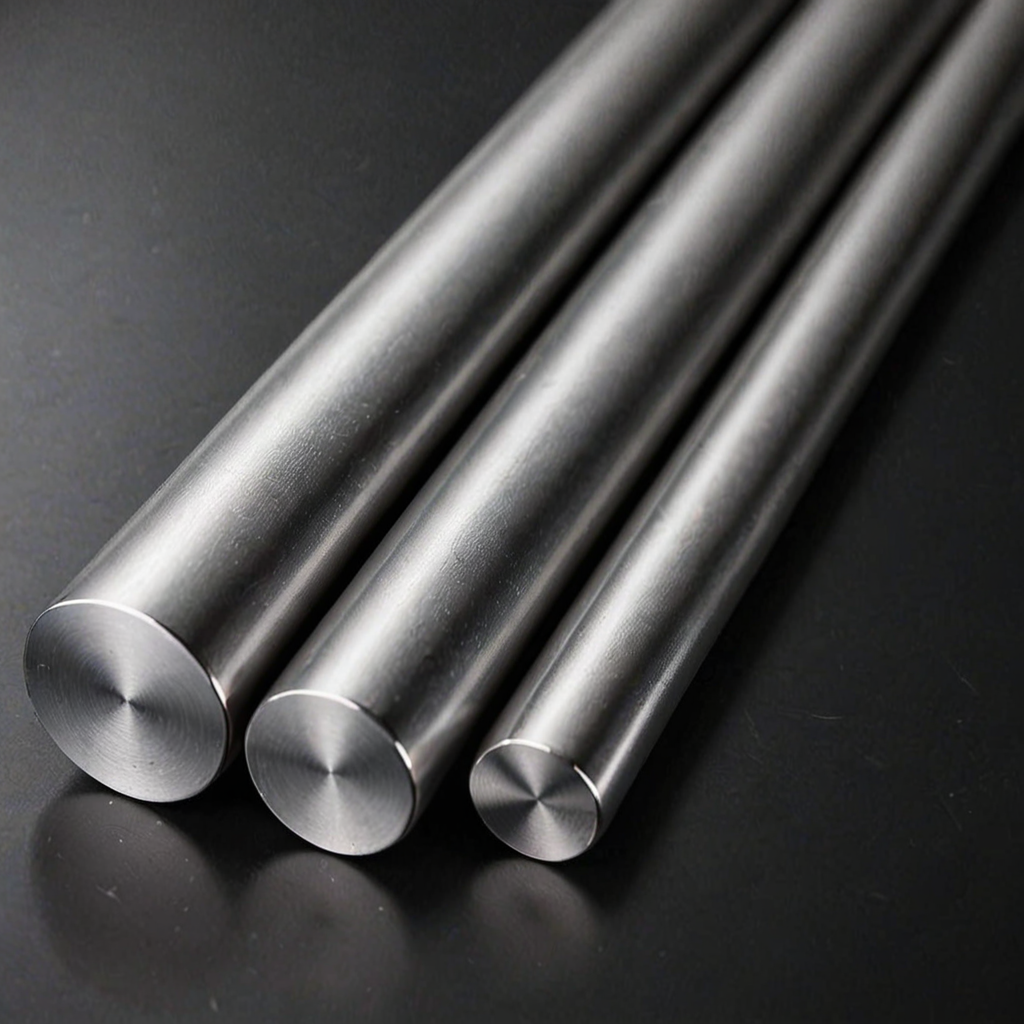

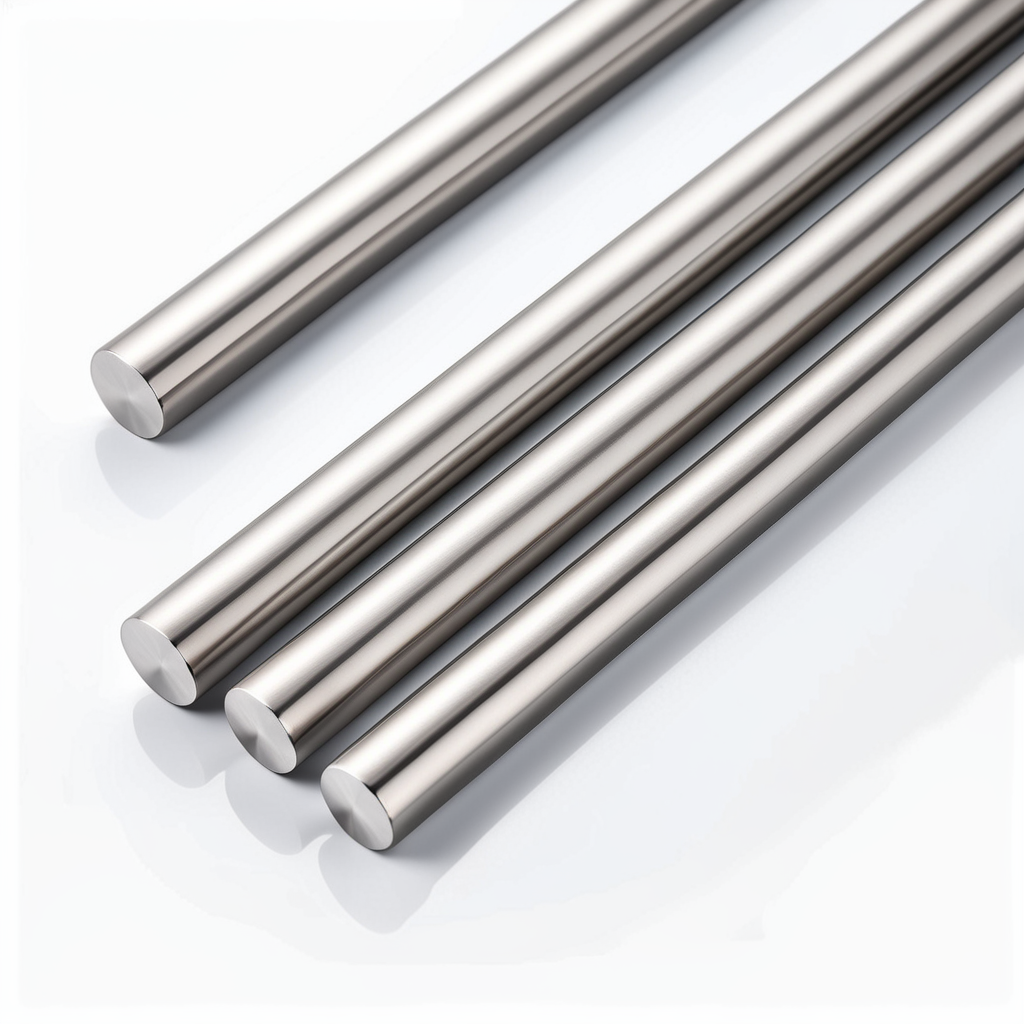

In modern manufacturing, CNC machining (Computer Numerical Control) has become one of the most important machining methods. It is widely used for producing various parts due to its precision, efficiency, and flexibility. When selecting materials, 304 stainless steel rods stand out for their unique advantages, especially high-precision 304 stainless steel rods, which perform exceptionally well in CNC machining. So, why choose high-precision 304 stainless steel rods for CNC machining? Let’s explore this in detail.

What is 304 Stainless Steel?

First, it’s essential to understand the basic characteristics of 304 stainless steel. 304 stainless steel is an austenitic stainless steel that contains 18% chromium and 8% nickel, often referred to as 18/8 stainless steel. It boasts excellent corrosion resistance, good mechanical properties, and high strength, making it a versatile and economical choice for many applications, especially in CNC machining.

Advantages of High-Precision 304 Stainless Steel Rods

In CNC machining, the quality of the material directly impacts the precision and performance of the finished product. Choosing high-precision 304 stainless steel rods can improve machining efficiency and ensure the quality and reliability of the parts. Here are the main advantages of using high-precision 304 stainless steel rods in CNC machining:

1. Excellent Corrosion Resistance

304 stainless steel’s corrosion resistance allows it to remain stable in various environments, especially in humid or oxidizing conditions. For parts that require long-term use, such as in food processing equipment, medical devices, and chemical containers, 304 stainless steel effectively prevents material degradation, extending the lifespan of the products.

2. High Precision Ensures Dimensional Stability

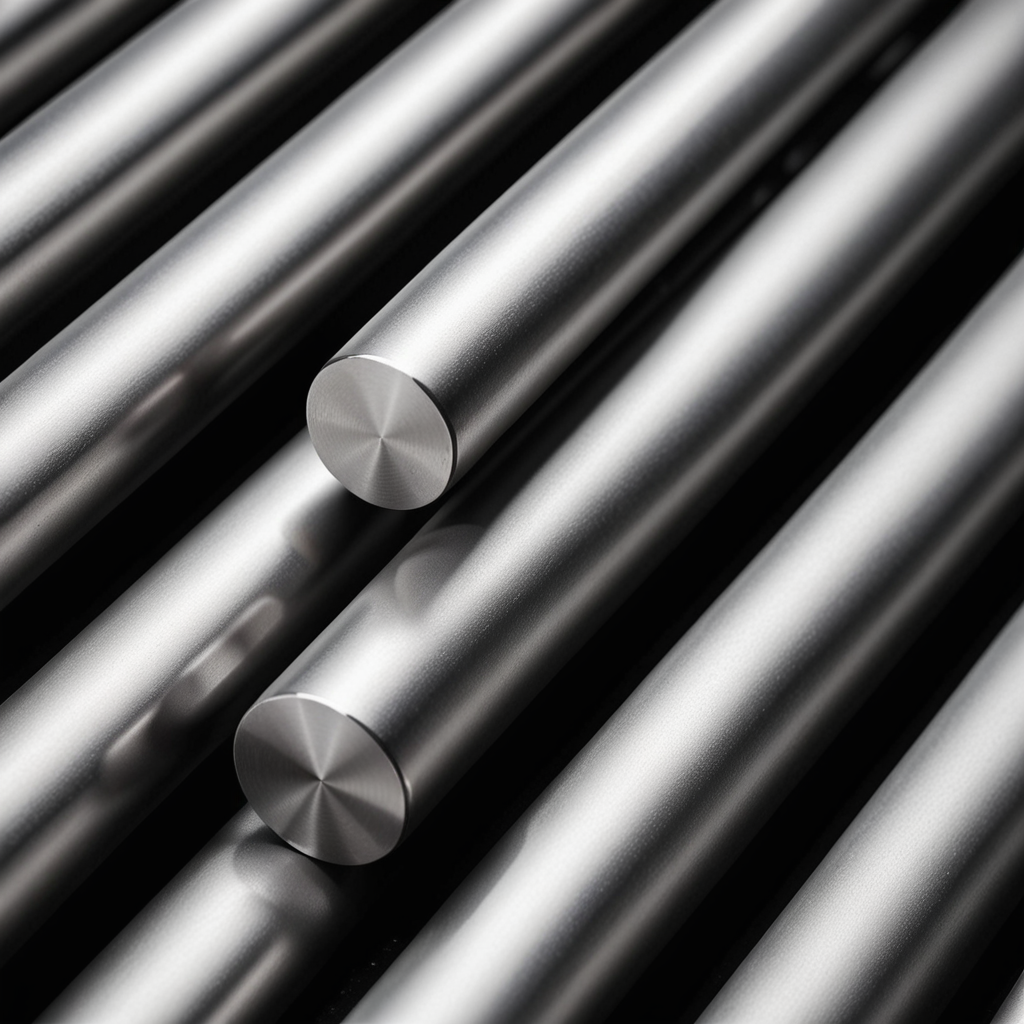

In CNC machining, precision is critical. High-precision 304 stainless steel rods ensure that the machined parts have excellent dimensional stability, reducing errors during machining. This is particularly important for parts that require tight tolerances, such as aerospace components and automotive parts. High-precision 304 stainless steel rods are manufactured under strict controls to ensure straightness and surface smoothness, thereby improving machining efficiency and product precision.

3. Excellent Machinability

304 stainless steel rods offer excellent machinability, especially in CNC processes. They can easily handle various machining techniques such as turning, milling, drilling, and cutting. The material’s balanced hardness ensures it won’t excessively wear out tools, significantly improving production efficiency and reducing tool change frequency, which in turn minimizes downtime.

4. Superior Mechanical Properties

304 stainless steel rods possess high strength and great toughness, making them resistant to deformation or cracking under high stress. For parts that need to withstand heavy loads, 304 stainless steel offers the necessary strength while maintaining high precision. This is crucial for industries such as automotive manufacturing and construction, where strength and precision are vital.

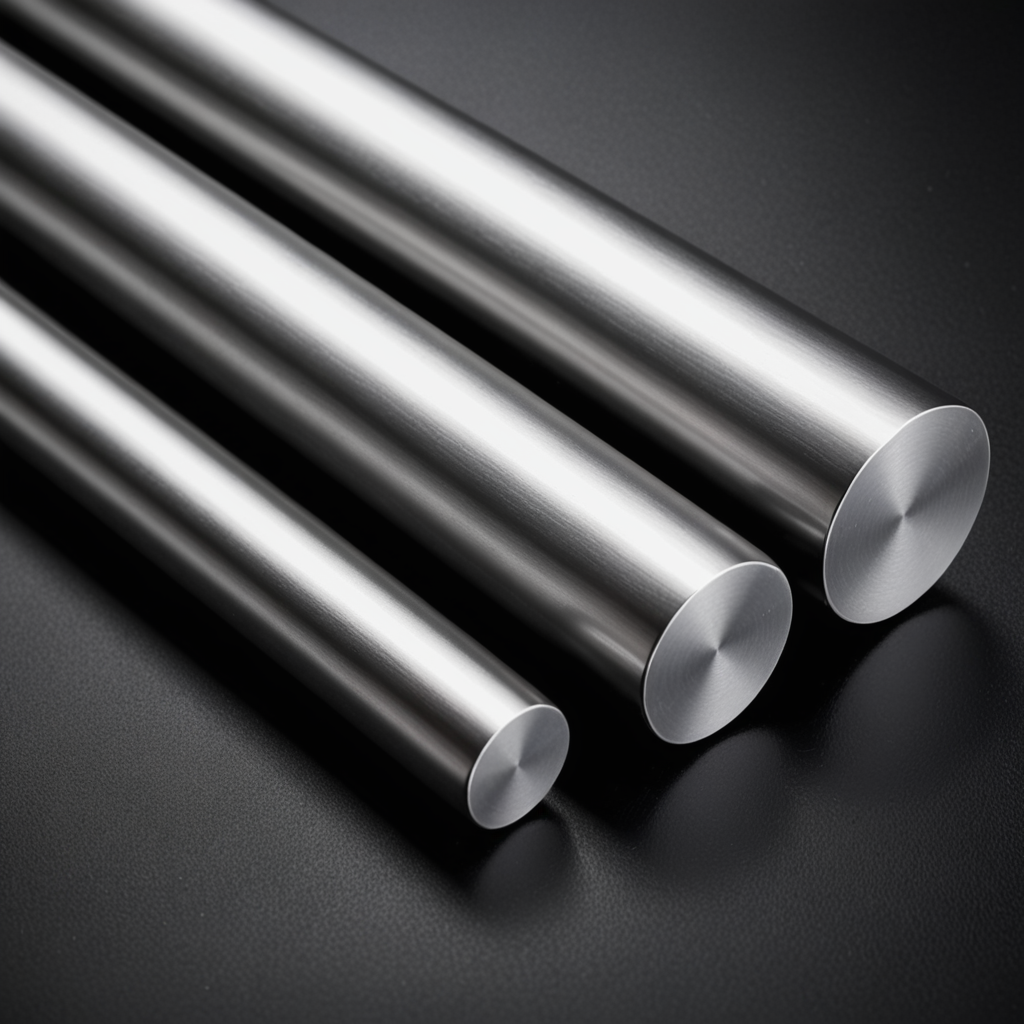

5. High Surface Finish Enhances Product Appearance

Using high-precision 304 stainless steel rods ensures a high surface finish, which is especially important for parts requiring a smooth and flawless appearance. For instance, in medical devices or premium consumer electronics, smooth, defect-free components not only improve product quality but also enhance the marketability of the final product.

Why is Precision Crucial in CNC Machining?

CNC machining is a highly precise method often used to produce complex parts with tight tolerances. If the material being used is not accurate or has slight imperfections, it can directly affect the machining results, causing the final product to fall short of the desired standards. This is why using high-precision 304 stainless steel rods is crucial in CNC machining. They reduce errors during production, ensuring that every part meets the design requirements.

Additionally, high-precision materials can shorten machining time. Since the material quality is superior, CNC machines can operate at higher speeds and feed rates, reducing processing time and enhancing production efficiency.

Applications of High-Precision 304 Stainless Steel Rods

Thanks to their outstanding properties, high-precision 304 stainless steel rods are widely used in various industries, especially in the following fields:

- Medical Devices: Such as surgical instruments and implants, which require materials with high precision and corrosion resistance.

- Food Processing: 304 stainless steel is widely used in food processing equipment like mixers and conveyors due to its corrosion resistance and safety.

- Automotive Manufacturing: High-precision 304 stainless steel is used to manufacture engine components and chassis structures, ensuring their strength and durability.

- Construction: 304 stainless steel rods are used in construction as structural support and decorative materials, combining aesthetics and durability.

Conclusion: Why Choose High-Precision 304 Stainless Steel Rods for CNC Machining?

In CNC machining, selecting the right material is essential, and high-precision 304 stainless steel rods stand out due to their corrosion resistance, dimensional stability, machinability, mechanical properties, and high surface finish. Whether it’s for producing high-precision components or for equipment that needs to withstand harsh conditions, 304 stainless steel rods provide excellent performance and reliability.

Therefore, if your project requires high-precision and high-performance materials, high-precision 304 stainless steel rods are a trusted choice. Not only can they enhance machining efficiency, but they also ensure the quality and durability of the final product.