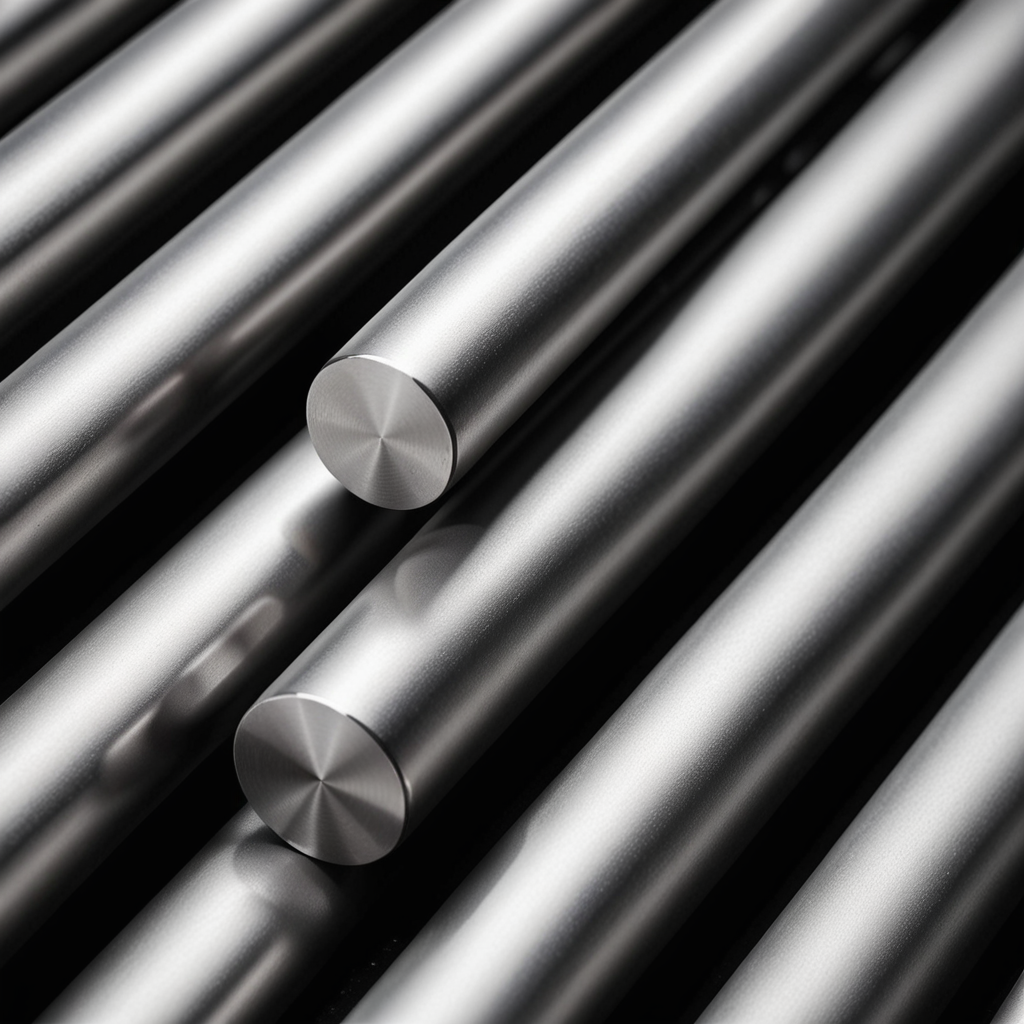

Why 303 Stainless Steel Bars Are the Best Choice for Precision Machining

When it comes to precision machining, choosing the right material is crucial. 303 stainless steel bars from Tongyi Metal stand out as one of the best options for industries requiring high-performance machining. Known for their exceptional machinability, durability, and resistance to corrosion, these bars provide the perfect balance of performance and affordability.

What Makes 303 Stainless Steel Bars Ideal for Machining?

303 stainless steel bars belong to the austenitic stainless steel family, offering excellent strength, corrosion resistance, and, importantly, machinability. Here’s why they are often the go-to choice for precision machining:

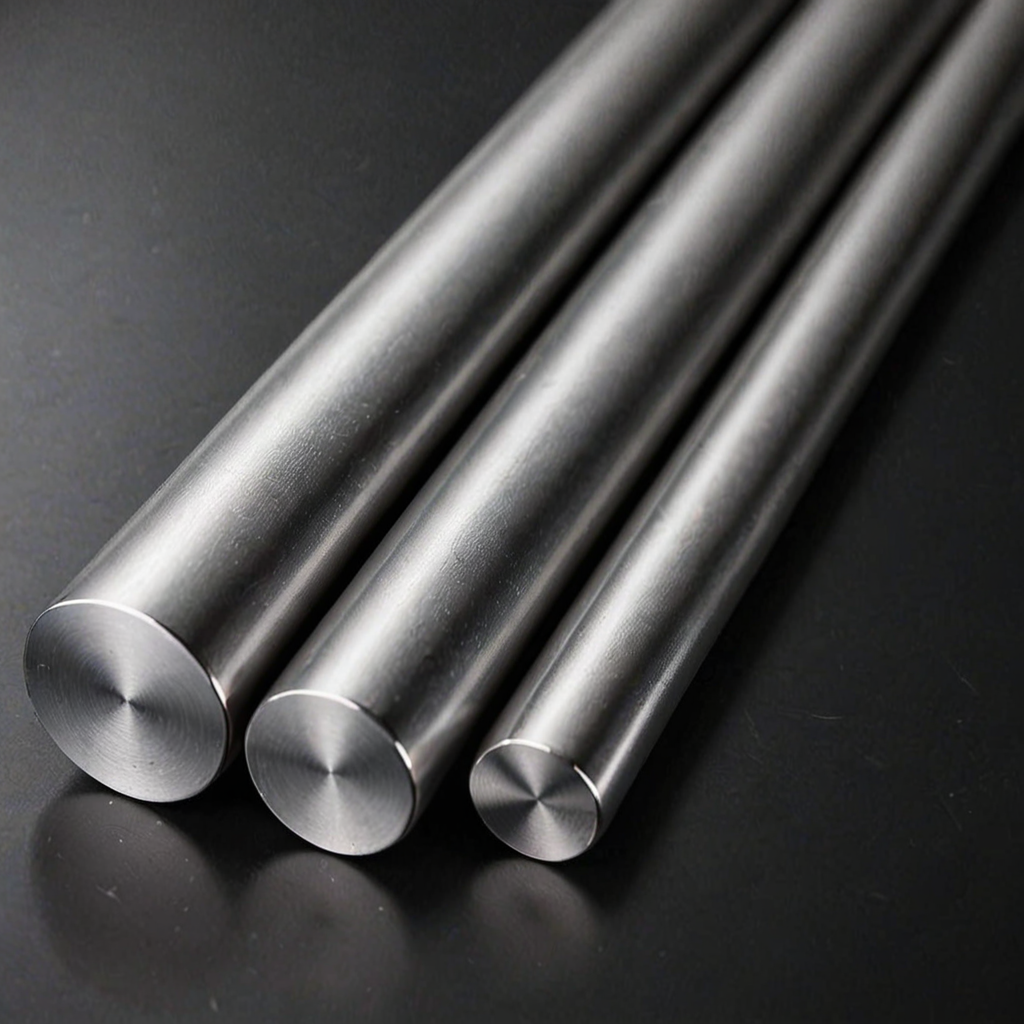

- Superior Machinability One of the main reasons for choosing 303 stainless steel bars is their ease of machining. Unlike other stainless steels, 303 contains sulfur and phosphorus, which help to reduce friction during cutting. This makes machining faster and more efficient, reducing wear on tools and improving overall productivity. Whether you’re cutting, drilling, or turning, 303 stainless steel bars make the job easier and more cost-effective.

- Excellent Corrosion Resistance 303 stainless steel bars offer excellent resistance to rust and corrosion, which is crucial in industries where exposure to moisture, chemicals, or salty environments is common. This is why many manufacturers in sectors such as medical, automotive, and food processing rely on 303 stainless steel bars for their durability and long-lasting performance.

- Strength and Durability While not as strong as some other stainless steel alloys, 303 stainless steel bars still offer significant strength and resistance to wear and tear. These bars are perfect for components that must withstand regular handling, mechanical stress, or harsh environments without failing.

- Versatility The versatility of 303 stainless steel bars makes them suitable for a wide variety of applications. From manufacturing precision fasteners and screws to producing components for machinery in industries like automotive, medical, and food processing, 303 stainless steel bars can be machined to meet the exact specifications needed for various products.

Benefits of Choosing 303 Stainless Steel Bars

| Benefit | Explanation |

|---|---|

| Machining Efficiency | The presence of sulfur and phosphorus makes machining easier and faster. |

| Corrosion Resistance | 303 bars resist rust and corrosion in moist and harsh environments. |

| Long-lasting Durability | They resist wear and tear, offering longevity in high-stress applications. |

| Cost-Effective | 303 stainless steel provides great performance at a competitive price. |

| Ideal for Precision | 303 stainless steel bars maintain accuracy and quality when machined to tight tolerances. |

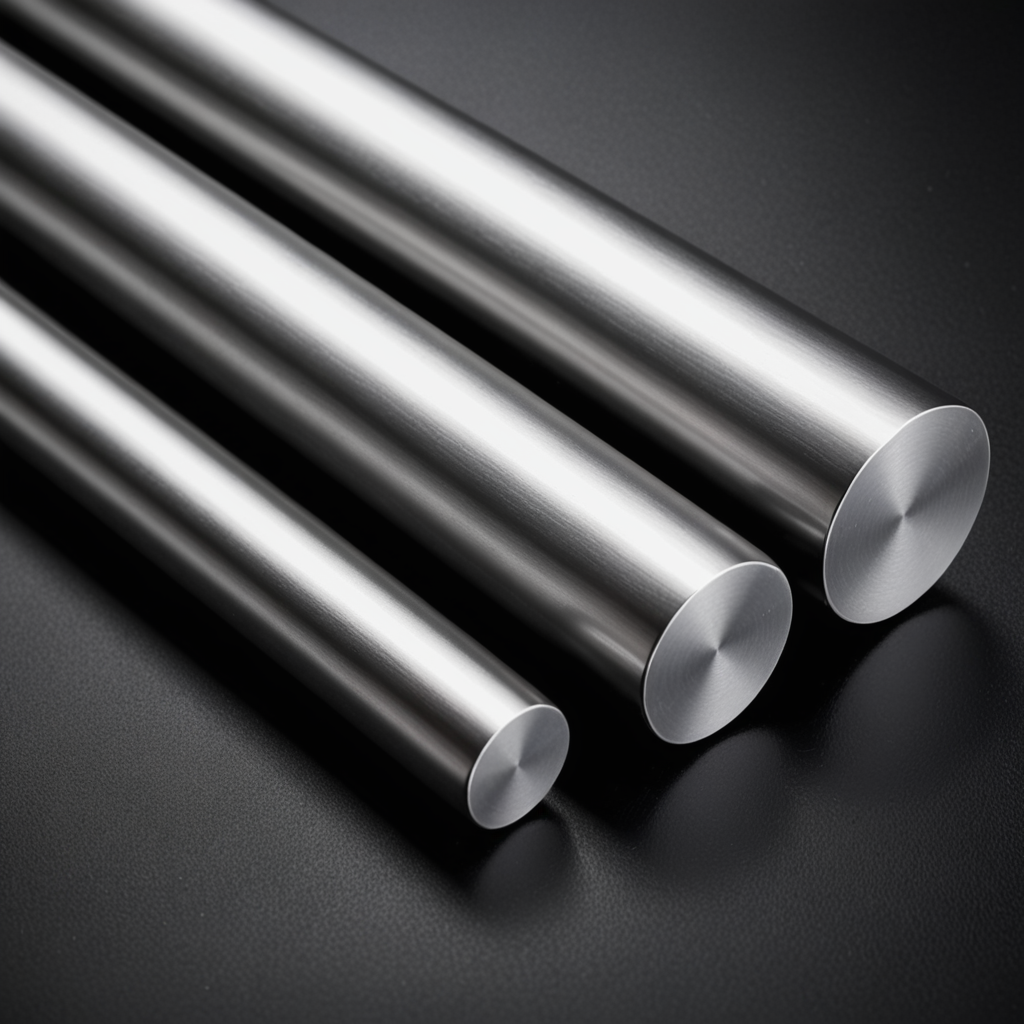

How to Get the Best Results When Machining 303 Stainless Steel Bars

To get the best performance from 303 stainless steel bars, following a few key machining tips is important:

- Use the Right Tools Make sure to use carbide or high-speed steel (HSS) tools, as these materials are best suited for machining stainless steel. These tools will ensure smoother cuts and prolong tool life.

- Control Cutting Speed Cutting speed is crucial when working with 303 stainless steel bars. Typically, cutting speeds between 80 and 200 feet per minute (SFM) are ideal. Too fast, and you risk excessive tool wear; too slow, and it can reduce machining efficiency.

- Use Coolants and Lubricants To keep things cool and prevent overheating, use the right coolants and lubricants during the machining process. These reduce friction and help ensure a smoother cutting process.

- Maintain Consistent Feed Rates Maintaining steady feed rates helps ensure that the surface finish remains smooth and consistent. Feed rates that are too high can lead to poor surface finishes, while rates that are too low can cause overheating.

Applications of 303 Stainless Steel Bars

303 stainless steel bars are used in a wide range of industries where precision, corrosion resistance, and durability are crucial. Here are some of the most common applications:

- Automotive: Components such as fasteners, shafts, and bolts.

- Medical: Surgical instruments, medical devices, and equipment that need to withstand sterilization.

- Food Processing: Equipment like food handling parts that must be resistant to corrosion and easy to clean.

303 stainless steel bars are the ideal choice for precision machining. Their excellent machinability, corrosion resistance, and versatility make them perfect for a variety of industries. With Tongyi Metal’s premium 303 stainless steel bars, you get a high-performance material at a competitive price, ensuring that your machining projects are both efficient and cost-effective.