Top 10 Common Stainless Steel Grades: A Complete Guide

Stainless steel is widely used across industries like manufacturing and machining due to its excellent corrosion resistance, mechanical properties, and versatility. For wholesale buyers and machining manufacturers, selecting the right stainless steel grade is crucial. This guide provides a detailed overview of the top ten common stainless steel grades, their characteristics, processing performance, and applications to help you make the best choice for your needs.

1. 304 Stainless Steel

| 304 | Cr | Ni | C | Mn | Si | P | S |

| 18.0-20.0 | 8.0-10.5 | ≤0.08 | ≤2.00 | ≤1.00 | ≤0.045 | ≤0.030 |

Product Features:

304 stainless steel is the most common austenitic stainless steel, composed of 18% chromium and 8% nickel. Known for its excellent corrosion resistance and oxidation resistance, it is ideal for general applications.

Processing Performance:

304 stainless steel is easy to cut, weld, and form, making it suitable for a wide range of industrial processes. It has good ductility, but processing under extreme conditions may present challenges.

Applications:

Widely used in industries such as food processing, medical equipment, chemical containers, and building decoration. It’s ideal for environments requiring both corrosion resistance and aesthetic appeal.

2. 316 Stainless Steel

| 316 | Cr | Ni | Mo | C | Mn | Si | P | S |

| 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | ≤0.08 | ≤2.00 | ≤1.00 | ≤0.045 | ≤0.030 |

Product Features:

316 stainless steel contains molybdenum (Mo), enhancing its corrosion resistance in marine and chemical environments, particularly in chloride-rich settings.

Processing Performance:

While slightly harder than 304, 316 stainless steel performs well during welding and is excellent for use in high-temperature and corrosive environments.

Applications:

Common in marine, chemical, pharmaceutical, and food processing industries, it’s perfect for seawater cooling systems, sewage treatment, and chemical reactors.

3. 430 Stainless Steel

| 430 | Cr | Ni | C | Mn | Si | P | S |

| 16.0-18.0 | ≤0.75 | ≤0.12 | ≤1.00 | ≤1.00 | ≤0.045 | ≤0.030 |

Product Features:

A ferritic stainless steel, 430 stainless steel contains 16-18% chromium and offers moderate corrosion resistance. It is magnetic and ideal for less demanding applications.

Processing Performance:

430 stainless steel is harder than austenitic grades, but it is easy to process and form. However, it’s not suitable for environments with severe corrosion.

Applications:

Used in automotive parts, household appliances, and general industrial equipment where lower corrosion resistance is acceptable.

4. 304L Stainless Steel

| 304L | Cr | Ni | C | Mn | Si | P | S |

| 18.0-20.0 | 8.0-12.0 | ≤0.03 | ≤2.00 | ≤1.00 | ≤0.045 | ≤0.030 |

Product Features:

304L is a low-carbon variant of 304 stainless steel, reducing the risk of carbon precipitation during welding and improving its welding performance.

Processing Performance:

304L maintains high corrosion resistance even in welded structures, making it ideal for high-quality welding tasks.

Applications:

Used in industries requiring corrosion resistance and high-quality welding, such as chemical equipment, nuclear energy, and the pharmaceutical industry.

5. 316L Stainless Steel

| 316L | Cr | Ni | Mo | C | Mn | Si | P | S |

| 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | ≤0.03 | ≤2.00 | ≤1.00 | ≤0.045 | ≤0.030 |

Product Features:

316L is the low-carbon version of 316, offering improved corrosion resistance and welding properties in chloride and acidic environments.

Processing Performance:

316L performs well in high-temperature and corrosive environments, maintaining its corrosion resistance even after welding.

Applications:

Commonly used in chemical reactors, seawater treatment plants, and food processing equipment.

6. 310 Stainless Steel

| 310 | Cr | Ni | C | Mn | Si | P | S |

| 24.0-26.0 | 19.0-22.0 | ≤0.25 | ≤2.00 | ≤1.50 | ≤0.045 | ≤0.030 |

Product Features:

310 stainless steel is high in chromium and nickel, providing exceptional resistance to high temperatures and oxidation.

Processing Performance:

Due to its high alloy composition, 310 stainless steel is difficult to process and requires specialized equipment, but it excels in high-temperature environments.

Applications:

Mainly used in high-temperature environments, such as furnace walls, heat exchangers, and high-temperature pipelines.

7. 904L Stainless Steel

| 904L | Cr | Ni | Mo | C | Mn | Si | P | S |

| 19.0-23.0 | 23.0-28.0 | 4.0-5.0 | ≤0.02 | ≤2.00 | ≤1.00 | ≤0.045 | ≤0.030 |

Product Features:

904L is an austenitic stainless steel with high amounts of nickel and molybdenum, offering exceptional corrosion resistance, particularly in strong acid and chloride environments.

Processing Performance:

Due to its high nickel and molybdenum content, 904L is harder to process but provides unparalleled corrosion resistance in most acidic environments.

Applications:

Used in industries like petrochemical, pharmaceutical, and marine engineering.

8. 2205 Duplex Stainless Steel

| 2205 | Cr | Ni | Mo | C | Mn | Si | P | S |

| 21.0-23.0 | 4.5-6.5 | 2.5-3.5 | ≤0.03 | 1.0-2.0 | ≤0.80 | ≤0.035 | ≤0.015 |

Product Features:

2205 is a duplex stainless steel, combining the strengths of both austenite and ferrite structures, offering high strength and good resistance to stress corrosion cracking.

Processing Performance:

2205 is suitable for most welding and forming processes, but stronger equipment and longer processing time may be required due to its higher strength.

Applications:

Used in marine, oil & gas, and chemical processing industries where both high strength and corrosion resistance are essential.

9. 17-4 PH Stainless Steel

| 17-4PH | Cr | Ni | Cu | C | Mn | Si | P | S |

| 15.0-17.5 | 3.0-5.0 | 3.0-5.0 | ≤0.07 | ≤1.00 | ≤1.00 | ≤0.045 | ≤0.030 |

Product Features:

17-4 PH is a precipitation-hardened stainless steel known for its high strength and good corrosion resistance. It can achieve varying levels of hardness through heat treatment.

Processing Performance:

It can provide high hardness and strength, making it suitable for high-stress environments, but requires precise control during heat treatment.

Applications:

Used in aerospace, military, and chemical industries to manufacture high-strength components like valves, gears, and bearings.

10. 430F Stainless Steel

Product Features:

| 430F | Cr | Ni | C | Mn | Si | P | S |

| 16.0-18.0 | ≤0.75 | ≤0.12 | ≤1.00 | ≤1.00 | ≤0.045 | 0.60-0.80 |

430F stainless steel is a sulfurized version of 430, designed for precision machining. The addition of sulfur improves its cutting performance.

Processing Performance:

430F excels in automated machining and high-precision component manufacturing due to its excellent cutting performance.

Applications:

Used in the production of precision parts, such as automotive parts, gears, and mechanical components.

Understanding the characteristics and application scenarios of different stainless steel grades is essential for wholesale buyers and machining manufacturers. By choosing the right stainless steel grade, you can enhance production efficiency and ensure the quality of your final product.

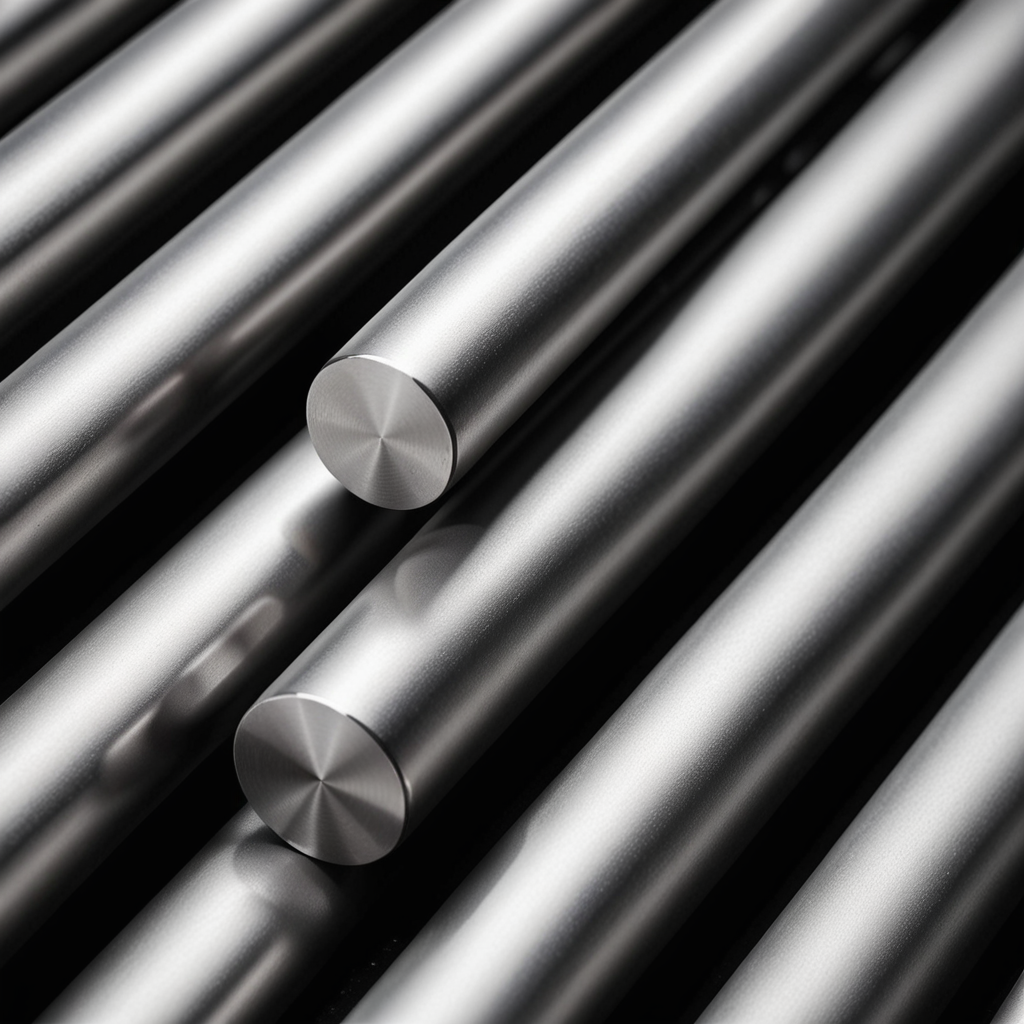

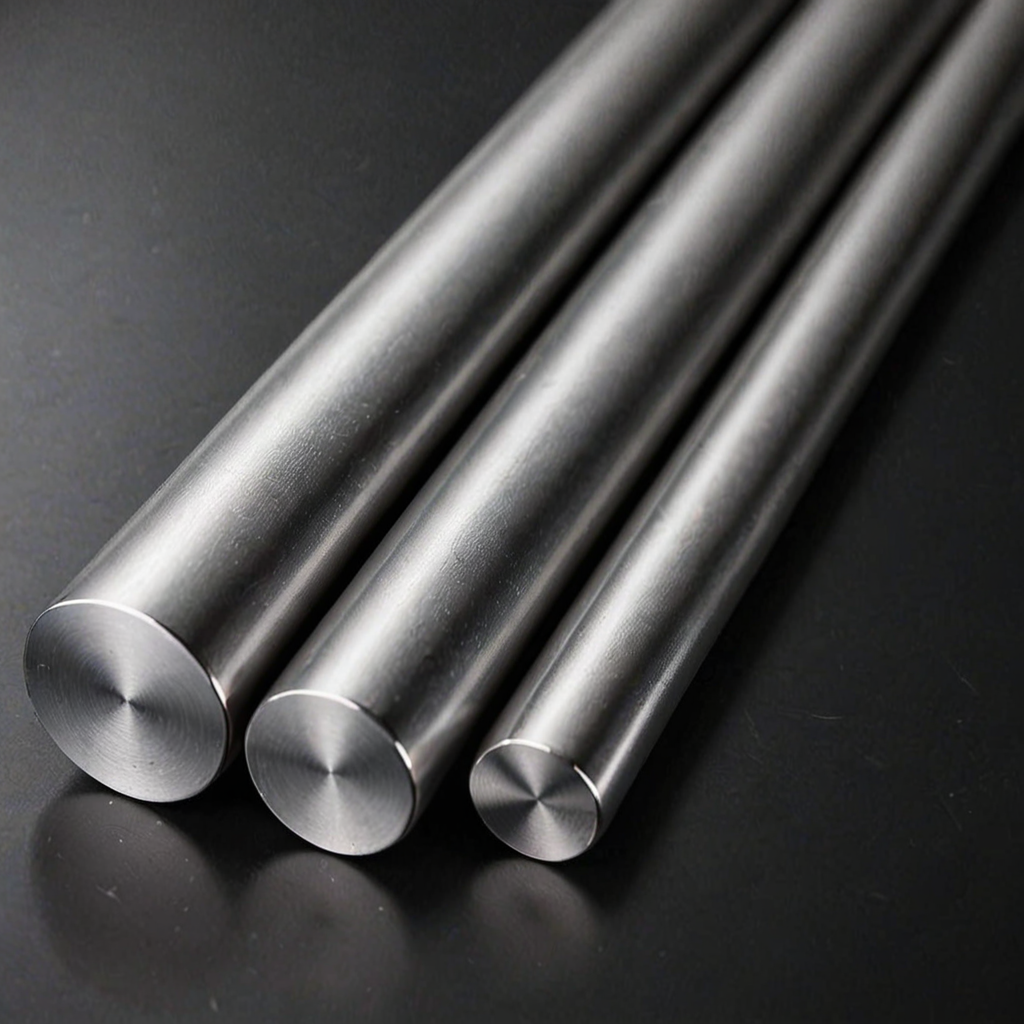

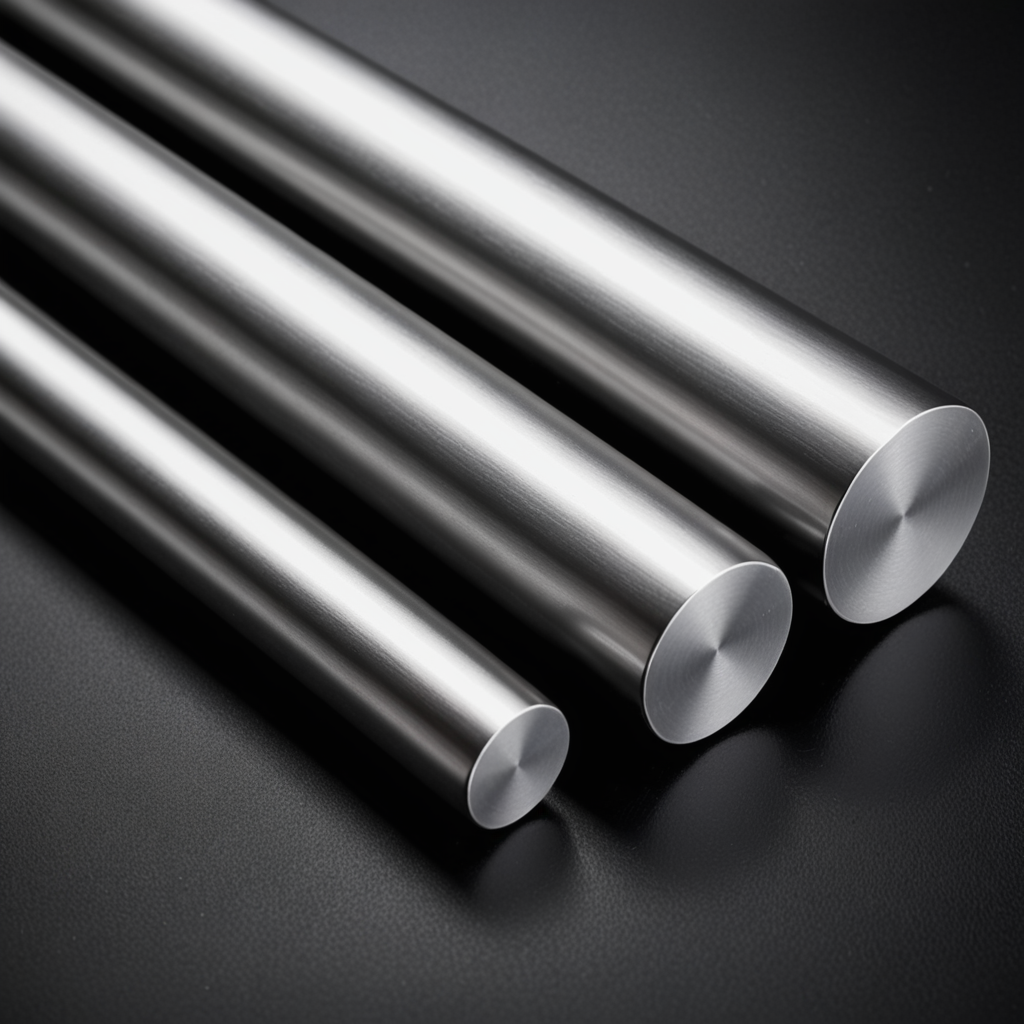

At Tongyi Metal, we specialize in the production of high-precision stainless steel products including stainless steel rods, tubes, and customized components. With an annual production capacity of 30,000 tons, we provide high-quality, high-accuracy products designed to meet the strict requirements of industries such as automotive, medical devices, machinery, and aerospace. Our products are well known for their superior dimensional accuracy, excellent surface finish, and the ability to customize lengths, hardness, and chemical compositions to meet your specific needs.

We offer a full range of services including cutting, grinding, and custom machining to provide you with tailored solutions that match your production requirements. Whether you’re looking for stainless steel for precision parts, small-scale production, or large-volume orders, we have the expertise and capability to deliver on time and within budget.

If you have any questions or need a detailed quotation, feel free to contact us. Tongyi Metal is committed to providing professional support and the most competitive pricing for all your stainless steel material needs.