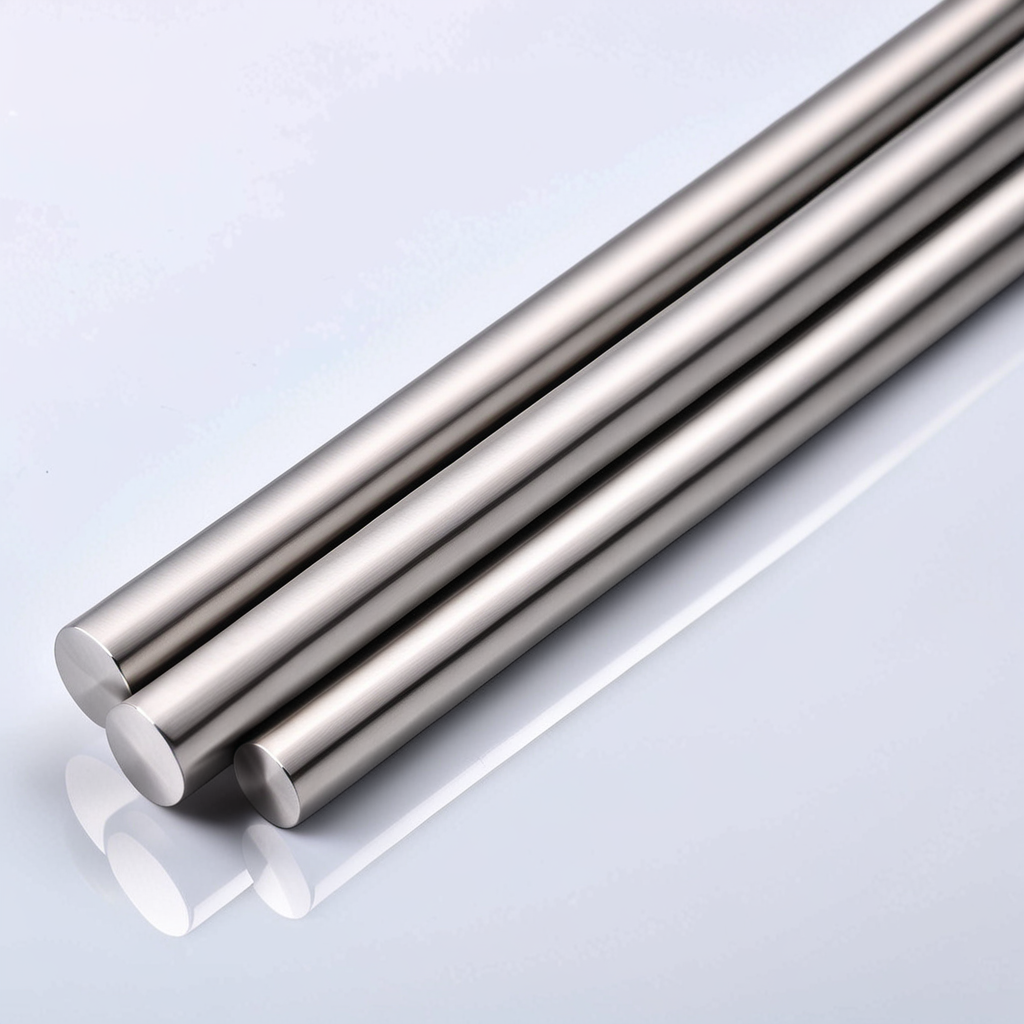

Stainless Steel Bars Applications and Common Specifications: A Complete Guide

Stainless steel bars are indispensable in many industries due to their superior properties such as corrosion resistance, strength, and versatility. These bars are used in applications ranging from manufacturing to aerospace. In this guide, we’ll explore the various applications and specifications of stainless steel bars to help you choose the best material for your project.

1. Key Applications of Stainless Steel Bars

Stainless steel bars find widespread use across various industries. Here are the most common applications:

- Manufacturing & Machining: Stainless steel bars are frequently used to produce precision components such as shafts, gears, and machine parts. Their durability and ease of machining make them ideal for creating high-quality mechanical components.

- Automotive Industry: Stainless steel bars are integral to automotive manufacturing. They are used in exhaust systems, chassis parts, and engine components due to their strength and corrosion resistance, which are crucial for automotive applications.

- Aerospace & Aviation: Aerospace applications require materials that can withstand extreme conditions. Stainless steel bars, especially 316 stainless steel, are used in aircraft components due to their exceptional resistance to corrosion and ability to endure high temperatures.

- Food Processing: Stainless steel bars, especially grades like 304 and 316, are commonly used in food processing equipment. Their resistance to corrosion and ease of cleaning make them perfect for machinery in the food industry.

2. Common Stainless Steel Bar Specifications

When selecting stainless steel bars, it’s important to consider the following specifications:

- Diameter: Stainless steel bars come in a variety of diameters, ranging from 6mm to 50mm or more. Smaller diameters are ideal for precision components, while larger bars are used in more substantial applications.

- Length: Stainless steel bars typically come in lengths from 1 meter to 6 meters. Custom lengths are available to meet specific requirements. Longer bars are suited for larger components, while shorter bars are perfect for high-precision parts.

- Surface Treatment: The surface finish of stainless steel bars affects both aesthetics and performance. Common finishes include brushed, polished, and bright finishes. A quality finish improves corrosion resistance and enhances the overall appearance.

- Material Grade: The grade of stainless steel used in bars affects their performance in different environments. For example, 304 stainless steel bars are commonly used for general purposes, while 316 stainless steel bars are ideal for environments exposed to harsh chemicals or seawater.

3. How to Choose the Right Stainless Steel Bar Material

Selecting the right stainless steel bar depends on your project’s specific requirements. Here are key factors to consider:

- Corrosion Resistance: For environments exposed to moisture, chemicals, or seawater, 316 stainless steel bars offer superior corrosion resistance. This grade is ideal for harsh applications such as marine environments or chemical processing.

- Strength and Durability: If your project requires high strength, stainless steel bars with higher tensile strength are essential. 304 stainless steel provides excellent strength for most applications, but 316 bars offer additional strength in extreme conditions.

- Cost Considerations: While 304 stainless steel bars are more affordable, 316 bars are priced higher due to their superior resistance to corrosion. Balance your project’s needs with your budget when making a selection.

- Custom Specifications: If you have specific requirements in terms of length, diameter, or surface finish, stainless steel bars can be custom-made. Work with a trusted supplier to ensure that the material meets your needs.

4. Types of Stainless Steel Bars

There are various types of stainless steel bars, each suited for different applications. Below are the most common ones:

- 304 Stainless Steel Bars: Known for their strength and corrosion resistance, 304 stainless steel bars are widely used in food processing, automotive manufacturing, and general mechanical applications. Their versatility makes them a go-to choice for many industries.

- 316 Stainless Steel Bars: For applications where corrosion resistance is crucial, 316 stainless steel bars are the best option. These bars are particularly well-suited for use in chemical processing, marine environments, and other challenging conditions.

- 430 Stainless Steel Bars: As a more affordable option, 430 stainless steel bars provide moderate corrosion resistance. They are commonly used in automotive, household appliances, and decorative applications, but are less durable than 304 or 316 grades.

5. Conclusion

Choosing the right stainless steel bar is essential to ensuring the success of your project. By understanding the different types and specifications, you can select the best material for your specific needs. Whether you are working on manufacturing, automotive, aerospace, or food processing applications, stainless steel bars offer strength, durability, and corrosion resistance to meet the demands of various industries.

For more information or to get expert advice on selecting the right stainless steel bars, contact Tongyi Metal, your trusted supplier of high-quality stainless steel bars.