- No. 51 Fuyang Road, Dalang Town, Dongguan City, Guangdong Province

- info@tongyimetal.com

- +8613650063736

| Alloy Designation | Main Component(%) | |||||||||||

| C | Si | Mu | P | S | Ni | Cr | Mo | Cu | Pb | N | more | |

| SUS303 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.20 | ≥0.15 | 8.00~10.00 | 17.00~19.00 | ≤0.60 | – | – | – | |

| SUS303CU | ≤0.15 | ≤1.00 | ≤3.00 | ≤0.20 | ≥0.15 | 8.00~10.00 | 17.00~19.00 | ≤0.60 | 1.50~3.50 | – | – | |

| SUS304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 8.00~10.50 | 18.00~20.00 | – | – | – | – | |

| SUS304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 9.00~13.00 | 18.00~20.00 | – | – | – | – | |

| 304FL | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 8.00~10.50 | 18.00~20.00 | – | – | – | – | |

| SUS310S | ≤0.08 | ≤1.50 | ≤2.00 | ≤0.045 | ≤0.030 | 19.00~22.00 | 24.00~26.00 | – | – | – | – | |

| SUS316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 | – | – | – | |

| SUS316L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 12.00~15.00 | 16.00~18.00 | 2.00~3.00 | – | – | – | |

| SUS316F | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≥0.10 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 | – | – | – | |

| SUS316Ti | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 | ≤0.1 | Ti:5×(C+N) ~ 0.70 | ||

| SUS321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 9.00~13.00 | 17.00~19.00 | – | – | – | – | |

| Alloy Designation | Main Component(%) | ||||||||||||||

| Main Component | Impurities(≤) | ||||||||||||||

| Ti | Al | Sn | Mo | Pd | Ni | Si | B | Fe | C | N | H | O | Other | ||

| Only | Total | ||||||||||||||

| TA1 | Margin | – | – | – | – | – | – | – | 0.2 | 0.08 | 0.03 | 0.015 | 0.18 | 0.1 | 0.4 |

| TA2 | Margin | – | – | – | – | – | – | – | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | 0.1 | 0.4 |

| TA3 | Margin | – | – | – | – | – | – | – | 0.3 | 0.08 | 0.05 | 0.015 | 0.35 | 0.1 | 0.4 |

| TA4 | Margin | – | – | – | – | – | – | – | 0.5 | 0.08 | 0.05 | 0.015 | 0.4 | 0.1 | 0.4 |

| TA5 | Margin | 3.3~4.7 | – | – | – | – | – | 0.005 | 0.3 | 0.08 | 0.04 | 0.015 | 0.15 | 0.1 | 0.4 |

| TA6 | Margin | 4.0~5.5 | – | – | – | – | – | – | 0.3 | 0.08 | 0.05 | 0.015 | 0.15 | 0.1 | 0.4 |

| TA7 | Margin | 4.0~6.0 | 2.0~3.0 | – | – | – | – | – | 0.5 | 0.08 | 0.05 | 0.015 | 0.2 | 0.1 | 0.4 |

| TA8 | Margin | – | – | – | 0.04~0.08 | – | – | – | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | 0.1 | 0.4 |

| TA9 | Margin | – | – | – | 0.12~0.25 | – | – | – | 0.25 | 0.08 | 0.03 | 0.015 | 0.2 | 0.1 | 0.4 |

| TA10 | Margin | – | – | 0.2~0.4 | – | 0.6~0.9 | – | – | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | 0.1 | 0.4 |

| Alloy Designation | Main Component(%) | |||||

| C | Si | Mn | P | S | more | |

| 1006 | Max 0.08 | 0.015~0.035 | 0.25~0.40 | ≤ 0.030 | ≤0.035 | – |

| 1008 | Max 0.10 | 0.015~0.035 | 0.30~0.50 | ≤ 0.030 | ≤0.035 | – |

| 1010 | 0.08~0.13 | 0.015~0.035 | 0.30~0.60 | ≤ 0.030 | ≤0.035 | – |

| 1015 | 0.13~0.18 | 0.015~0.035 | 0.30~0.60 | ≤ 0.030 | ≤0.035 | – |

| 1020 | 0.18~0.23 | 0.015~0.035 | 0.30~0.60 | ≤ 0.030 | ≤0.035 | – |

| 1021 | 0.18~0.23 | 0.015~0.035 | 0.60~0.90 | ≤ 0.030 | ≤0.035 | – |

| 1022 | 0.18~0.23 | 0.015~0.035 | 0.70~1.00 | ≤ 0.030 | ≤0.035 | – |

| 1025 | 0.22~0.28 | 0.015~0.035 | 0.30~0.60 | ≤ 0.030 | ≤0.035 | – |

| 1030 | 0.27~0.33 | 0.015~0.035 | 0.60~0.90 | ≤ 0.030 | ≤0.035 | – |

| 1035 | 0.32~0.38 | 0.015~0.035 | 0.60~0.90 | ≤ 0.030 | ≤0.035 | – |

| 1045 | 0.42~0.48 | 0.015~0.035 | 0.60~0.90 | ≤ 0.030 | ≤0.035 | – |

| 1050 | 0.47~0.53 | 0.015~0.035 | 0.60~0.90 | ≤ 0.030 | ≤0.035 | – |

| 1055 | 0.52~0.58 | 0.015~0.035 | 0.60~0.90 | ≤ 0.030 | ≤0.035 | – |

| 1060 | 0.55~0.65 | 0.015~0.035 | 0.60~0.90 | ≤ 0.030 | ≤0.035 | – |

| Alloy Designation | Main Component(%) | |||||||||||||

| C | Si | Mn | Cr | Ni | Al | Ti | Cu | Mo | P | S | Fe | Nb | more | |

| Incoloy 800 | ≤0.10 | ≤ 1.0 | ≤1.5 | 19.0~23.0 | 30~35 | 0.15~0.60 | 0.15~0.60 | ≤0.75 | ≤0.02 | ≤0.015 | ≥39.5 | |||

| Incoloy 800H | 0.05~0.10 | ≤ 1.0 | ≤1.5 | 19.0~23.0 | 30~35 | 0.15~0.60 | 0.15~0.60 | ≤0.75 | ≤0.02 | ≤0.015 | ≥39.5 | Al+Ti: 0.30~1.20 | ||

| Incoloy 825 | ≤0.05 | ≤ 0.50 | ≤1.0 | 19.5~23.5 | 38~46 | ≤0.20 | 0.60~1.20 | 1.5~3.0 | 2.5~3.5 | ≤0.030 | ≥22 | |||

| Inconel 600 | ≤0.15 | ≤ 0.50 | ≤1.0 | 14.0~17.0 | ≥72 | ≤0.50 | ≤0.015 | 6.0~10 | ||||||

| Inconel 625 | ≤0.10 | ≤0.50 | ≤0.50 | 20.0~30.0 | ≥58 | ≤0.40 | ≤0.40 | 8.0~10 | ≤0.015 | ≤0.015 | ≤5.0 | 3.15~4.15 | Co: ≤1.0 | |

| Monel 400 | ≤0.3 | ≤ 0.50 | ≤2.0 | ≥63 | 28~34 | ≤0.024 | ≤2.5 | |||||||

316L stainless steel pipe is a low-carbon molybdenum-alloyed austenitic stainless steel that offers excellent corrosion resistance and good weldability. Due to its low carbon content, carbide precipitation at grain boundaries is minimized after welding or stress relief, maintaining outstanding corrosion resistance in various environments. It is widely used in industries requiring high corrosion resistance, such as chemical processing, marine engineering, and pharmaceuticals.

316L stainless steel pipe exhibits stronger resistance to pitting and crevice corrosion in chloride-containing environments. Its good high-temperature strength and creep resistance make it suitable for applications in high-temperature environments. The excellent formability and weldability also make it ideal for manufacturing complex components.

It should be noted that although 316L has exceptional corrosion resistance, it may not perform as well as higher-alloyed stainless steels in certain strongly oxidizing acids. Therefore, material selection should be reasonably evaluated based on specific usage environments and requirements.

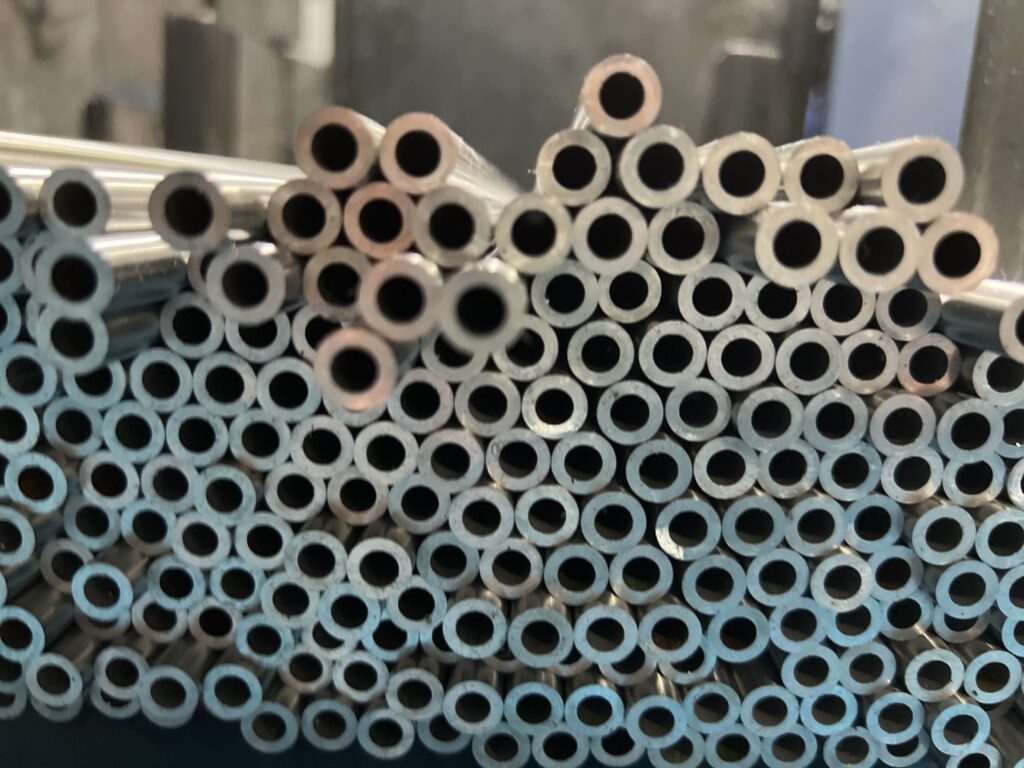

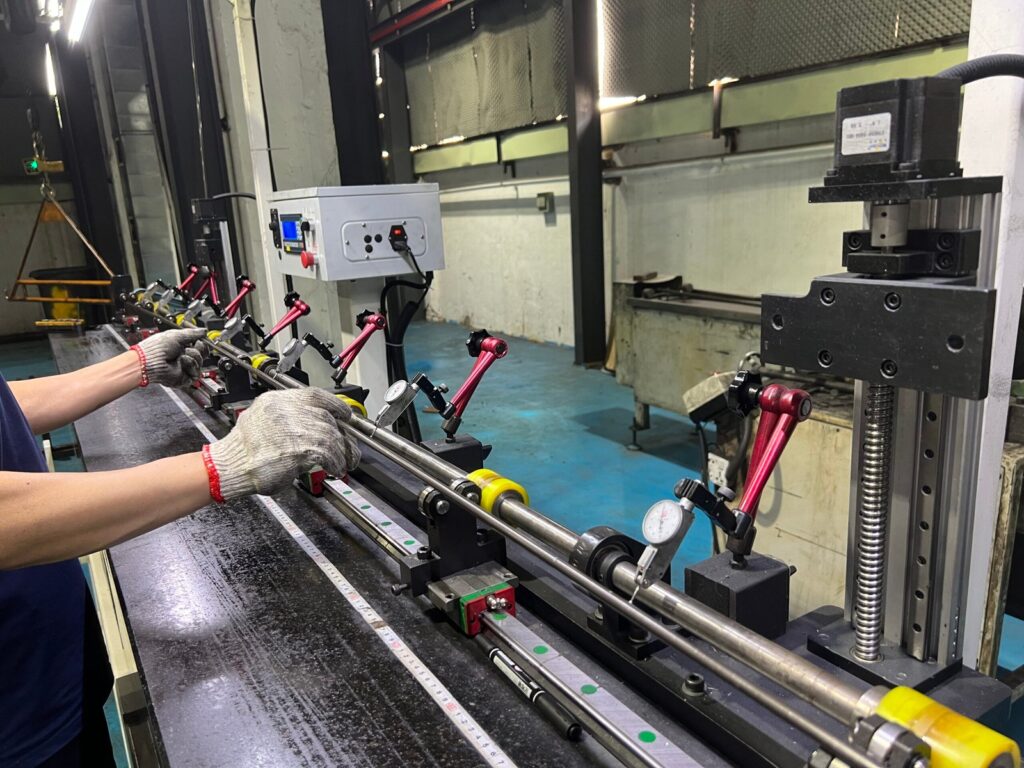

Tongyi Metal’s stainless steel pipes are produced using advanced manufacturing processes and strict quality control, ensuring that the pipes exhibit high precision, high straightness, and a high-quality surface finish. These characteristics make our products highly suitable for various applications, including precision manufacturing, fluid transportation, and structural support.

Straightness of stainless steel pipes can reach a maximum of ≤ 0.05mm, which can effectively reduce equipment wear and improve processing stability.

Maximum precision of outer diameter tolerance can reach ≤ 0.005mm, which improves the efficiency of mechanical processing and reduces assembly errors

Stainless steel pipe length can be customized according to requirements to avoid unnecessary cutting and waste, and reduce costs

Uniform thickness of stainless steel pipes makes subsequent processing more convenient and reduces processing difficulty

Customized seamless tubes meet your specific processing needs, offering flexible size and specification options to ensure optimal performance and adaptability. Our custom seamless steel pipes can be tailored to your specific requirements for tolerance, straightness, length, and wall thickness, ensuring the best results in various application scenarios. This approach enhances your processing efficiency while maximizing cost savings.

Our company’s products are suitable for various fields such as digital products, electrical appliances, medical, office equipment, power clocks, electromechanical, robotics, automotive, electronics, etc. We strive to create high-quality products in the industry.

Guangdong tongyi metal technology co., ltd. Is a leading brand specializing in the production of precision special steel. We offer a wide range of standard products and excel in providing custom steel grades, shape customization, and bulk orders to meet the stringent requirements of precision hardware parts processing. driving technological innovation and delivering high-quality metal materials and solutions to our clients.

We have 168 imported high-precision equipment and more than 30 core technicians.

Up to 30000 tons of metal materials can be produced annually

We collaborate with over 10000 strategic partners globally

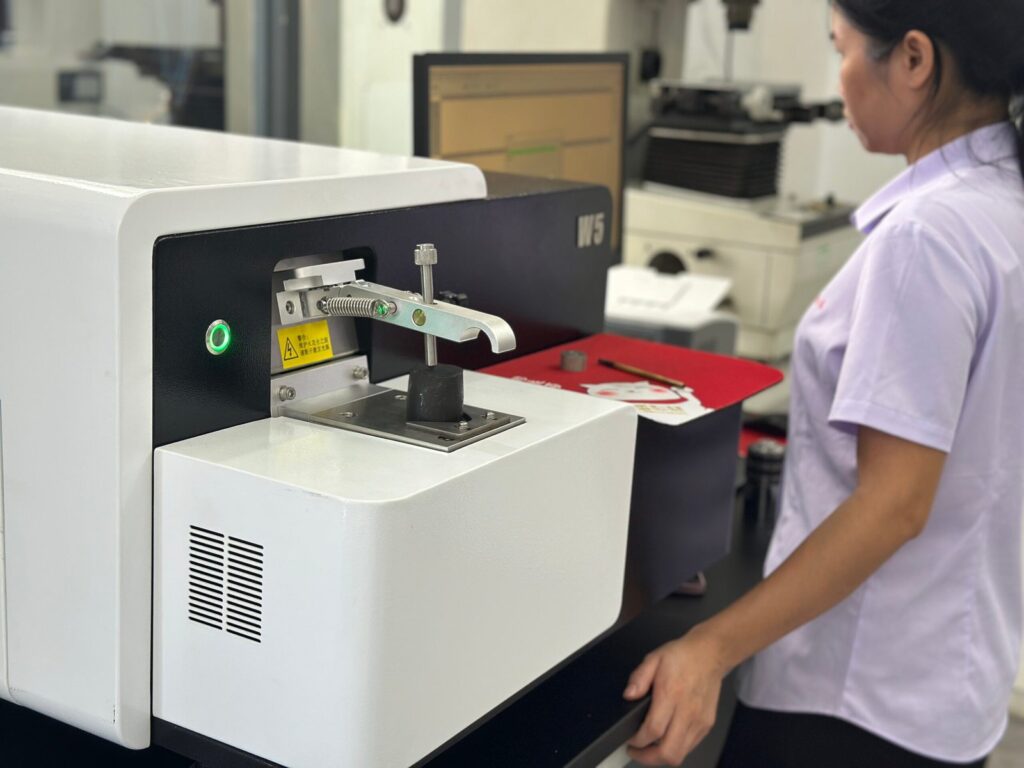

The company has more than 100 production equipment imported from japan and 38 core technicians. Strictly implement iso9001 management system in the production process, import high-precision testing equipment can provide accurate data support to win customer trust and support with high quality and fast delivery.

The same metal has 68 sets of measuring equipment imported from Japan, such as Mitoyo micrometer, straightness test, hardness tester, spectrometer, magnetic detector, etc. The outer diameter accuracy of the material is measured once every 5 minutes, and the quality is all qualified before packaging and shipping.

The same metal has 15 years of stainless steel rod/wire material research and development, design, production experience, foreign large strength manufacturers. Customized matching material solutions according to customer needs in various industries.

offers clear and concise answers to the most frequently asked questions about our stainless steel bars, ensuring you get the information you need quickly and efficiently.

We offer a variety of stainless steel, titanium alloy, quenched and tempered steel bars and wires, including 303, 304, 316, 410, and more. We can also customize the composition according to your requirements.

Yes, we can customize the length of stainless steel bars according to the specific requirements of our customers, reducing material waste and lowering costs.

Our stainless steel bars are widely used in various industries, including construction, automotive, medical devices, food processing, and aerospace.

We offer a variety of surface treatment options, including polishing, brushing, pickling, and mirror finishing, to meet different application needs.

We adhere to the ISO9001 quality management system, conducting strict quality control at every stage from raw material procurement to the production process, and we also offer third-party inspection services.

Materials, appearance, dimensions, straightness, smoothness, etc. can be customized according to needs

Materials, appearance, dimensions, straightness, smoothness, etc. can be customized according to needs