Potential Applications of 304 Stainless Steel Rods in Aerospace

The aerospace industry demands materials with exceptional strength, corrosion resistance, and durability under extreme conditions. 304 stainless steel rods, known for their excellent mechanical properties and oxidation resistance, offer a cost-effective alternative to specialty alloys. This article explores the potential applications of 304 stainless steel in aerospace engineering.

Why 304 Stainless Steel for Aerospace?

304 stainless steel is widely used due to its:

- High strength-to-weight ratio

- Excellent corrosion resistance

- Good machinability and weldability

- Cost-effectiveness compared to aerospace-grade alloys

Comparison of 304 Stainless Steel with Other Aerospace Materials

| Material | Strength | Corrosion Resistance | Temperature Resistance | Cost |

|---|---|---|---|---|

| 304 Stainless Steel | Moderate | Excellent | Up to 870°C (1600°F) | Low |

| Titanium Alloys | High | Excellent | Up to 980°C (1800°F) | High |

| Aluminum Alloys | Low | Moderate | Up to 660°C (1220°F) | Moderate |

| Nickel Alloys | Very High | Excellent | Up to 1100°C (2000°F) | Very High |

Key Aerospace Applications of 304 Stainless Steel Rods

1) Structural Components

304 stainless steel rods can be used in secondary structures, such as fasteners, brackets, and support frames, where corrosion resistance is critical.

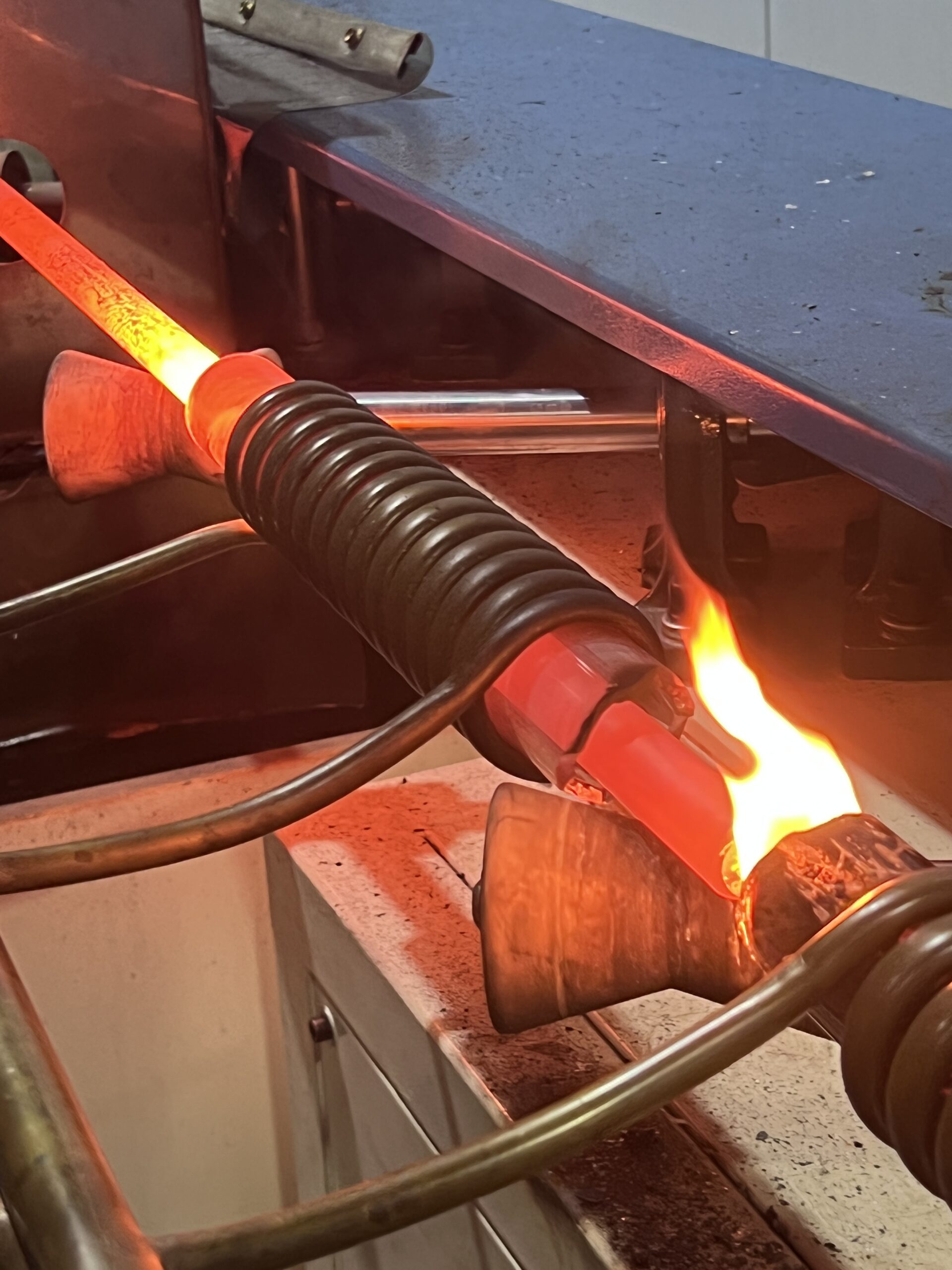

2) Exhaust and Engine Systems

With its high-temperature oxidation resistance, 304 stainless steel is suitable for exhaust ducts, heat shields, and other engine components.

3) Fuel and Hydraulic Systems

The excellent corrosion resistance of 304 stainless steel makes it ideal for fuel line tubing and hydraulic systems, where exposure to various chemicals is common.

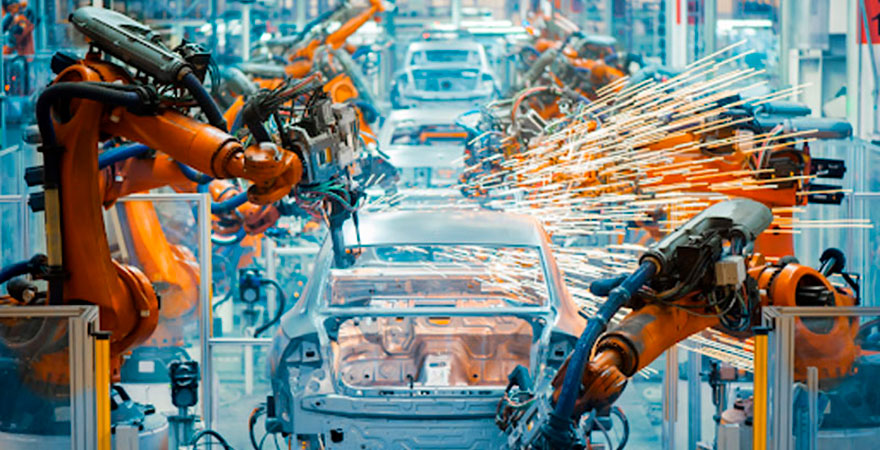

4) Aerospace Tooling and Ground Equipment

304 stainless steel rods are often used in the production of aerospace tooling, maintenance equipment, and ground support structures due to their durability.

Limitations of 304 Stainless Steel in Aerospace

Despite its advantages, 304 stainless steel has limitations:

- Not as strong as titanium or nickel alloys

- Susceptible to carbide precipitation at high temperatures

- Heavier than aluminum, which can limit its use in weight-sensitive applications

304 stainless steel rods offer a cost-effective solution for various aerospace applications, particularly in non-structural and high-corrosion environments. While not a complete replacement for titanium or nickel-based alloys, 304 stainless steel remains an essential material in the aerospace industry.

Looking for high-quality 304 stainless steel rods? Contact us today