Machining 303 Stainless Steel: What You Need to Know

If you’re looking for a stainless steel that’s easy to machine and resistant to corrosion, 303 stainless steel is a great choice. It’s used in many industries, including automotive, medical, and food processing. Whether you’re new to machining or have experience, understanding the key points of machining 303 stainless steel can make your job easier.

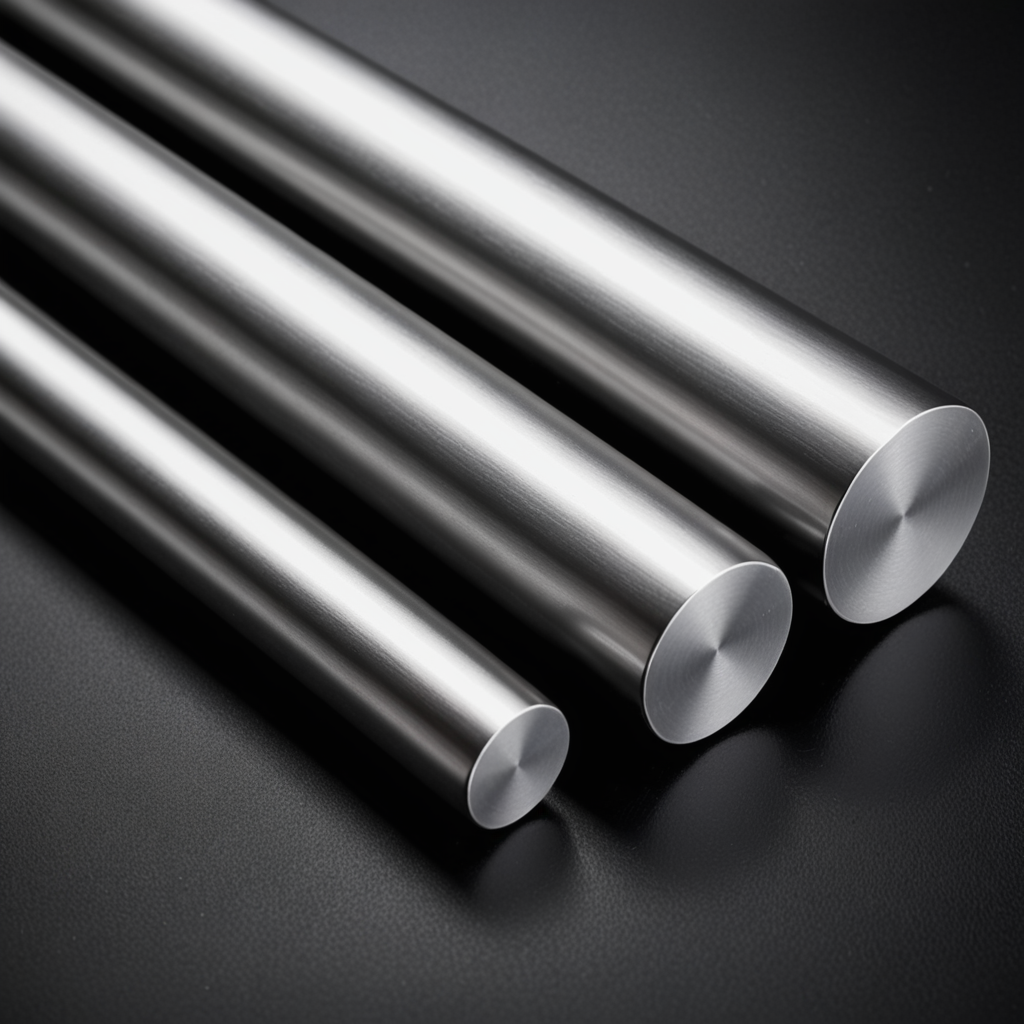

Why Choose 303 Stainless Steel?

303 stainless steel is a type of austenitic stainless steel. It is especially easy to machine, making it a popular choice for precise work. It’s easier to cut and form than 304 stainless steel. This makes it perfect for jobs that require exact dimensions.

Here are some key reasons to choose 303 stainless steel:

- Easy to Machine: Thanks to sulfur added to the alloy, 303 stainless steel is easier to machine compared to other stainless steels. This helps you achieve precision cuts without too much effort.

- Corrosion-Resistant: It resists corrosion well and can maintain its strength even in harsh environments.

- Affordable: While 303 is cost-effective, it still offers good performance, making it a popular choice for a wide range of applications.

Tips for Machining 303 Stainless Steel

- Choose the Right Tools Tool choice is important when machining 303 stainless steel. Carbide tools are good for high-speed machining, while high-speed steel (HSS) tools are better for regular machining. The right tool for the job can make the process more efficient and precise.

- Control the Cutting Speed The right cutting speed is essential for good results. Cutting at speeds between 80 and 200 feet per minute (SFM) is ideal. Going too fast can cause tool wear, while going too slow can lower efficiency.

- Use Coolants or Lubricants Machining generates heat. Using coolants or lubricants helps keep the temperature down, reducing tool wear and improving the quality of the finished part.

- Maintain a Steady Feed Rate The feed rate should stay consistent. A feed rate that’s too fast can result in a rough surface, while one that’s too slow can increase friction and slow down the process. A balanced feed rate is key to good results.

- Avoid Workpiece Hardening 303 stainless steel can harden during machining, especially if cooling is inadequate. Workpiece hardening can cause the tools to wear out more quickly and lead to poor surface quality.

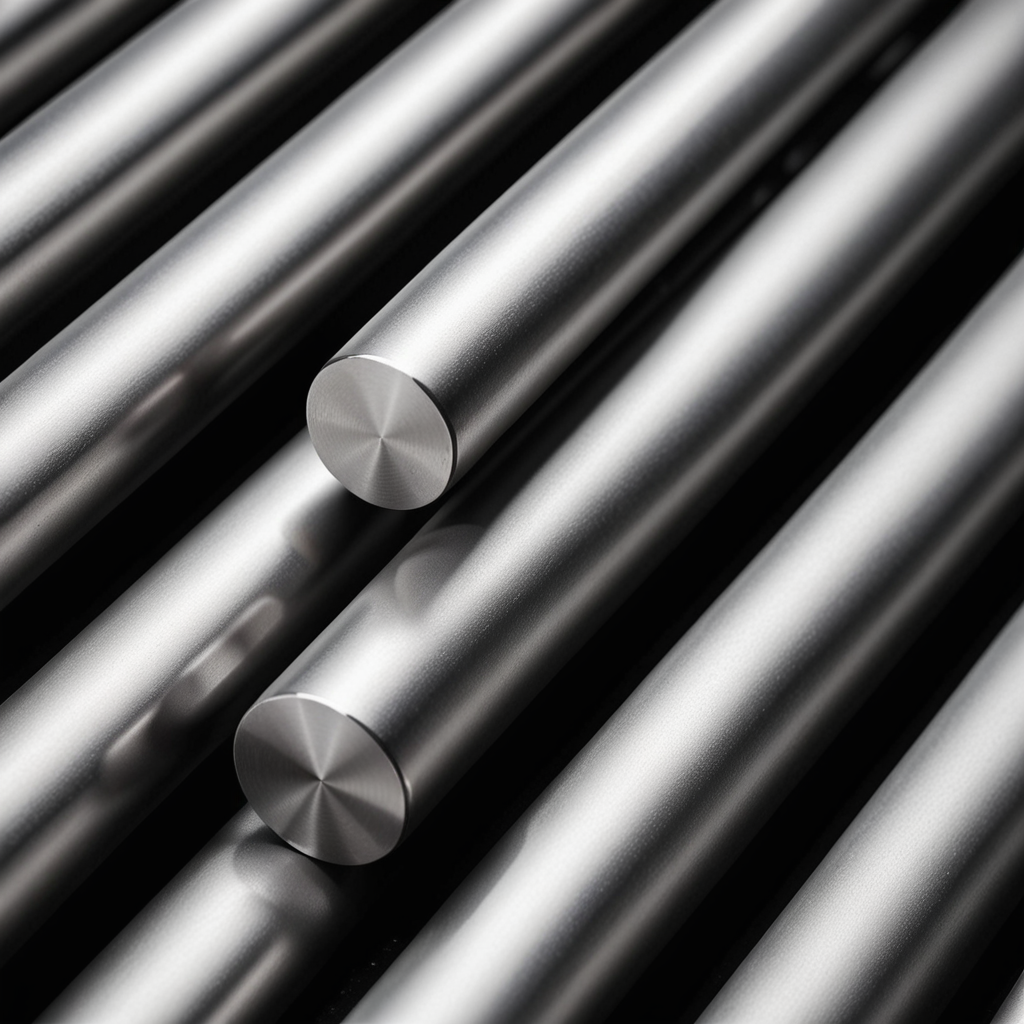

Common Challenges in Machining 303 Stainless Steel Rods

While 303 stainless steel is relatively easy to machine, there are still some challenges to watch out for:

- Workpiece Hardening: If the workpiece overheats or cooling fluids are not used properly, a hardened layer can form on the surface, making further machining harder.

- Tool Wear: Even though 303 stainless steel is easier to machine, it still causes more tool wear than other materials like carbon steel. Choosing the right tools and settings helps minimize this issue.

- Surface Quality: Incorrect cutting speed or tool choice can result in a rough surface, which may require additional work.

Where is 303 Stainless Steel Used?

303 stainless steel is widely used in industries that require precision and strong resistance to corrosion. Here are some common applications:

- Medical Devices: Thanks to its excellent corrosion resistance, 303 stainless steel is used in medical tools and implants.

- Automotive: 303 stainless steel is used in automotive parts like bolts, gears, and brackets, where it needs to handle high strength and temperature.

- Food Processing: It is also used in food processing equipment because of its resistance to corrosion and ease of cleaning.

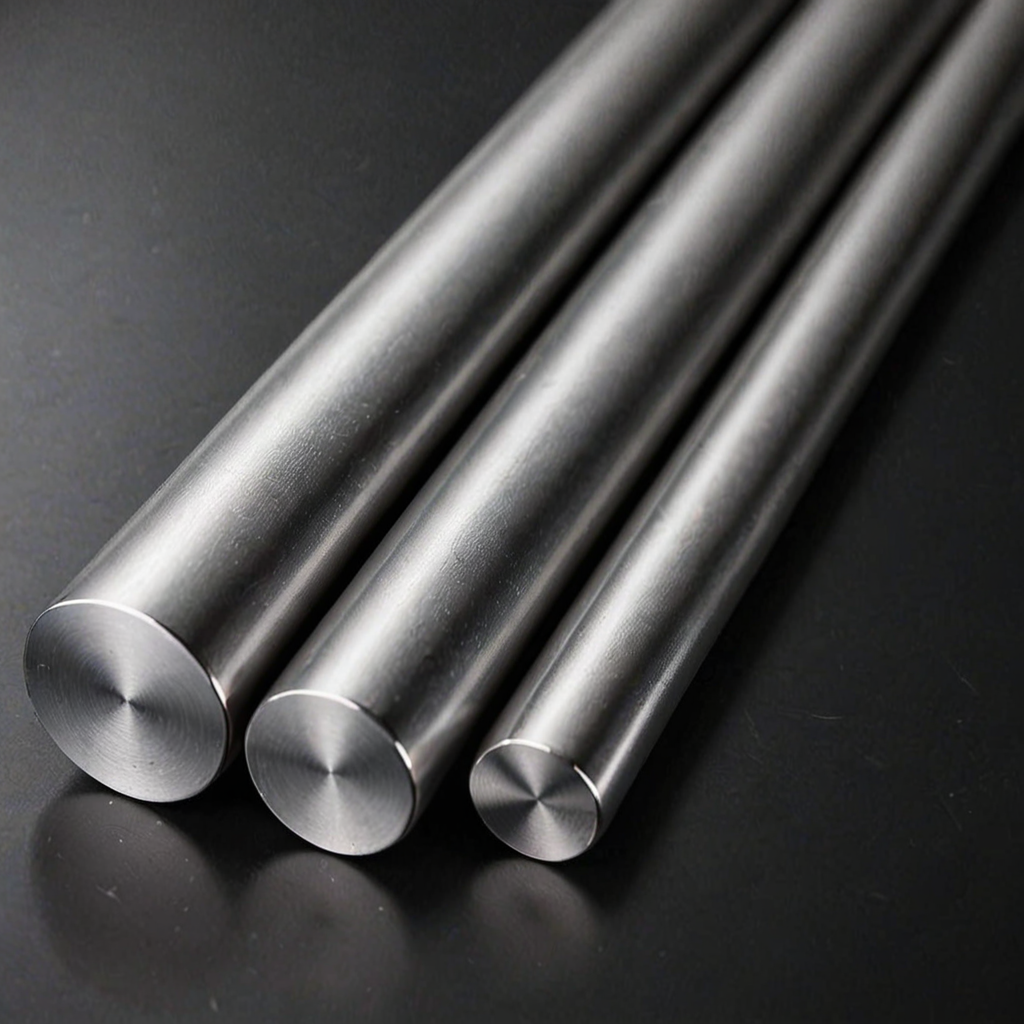

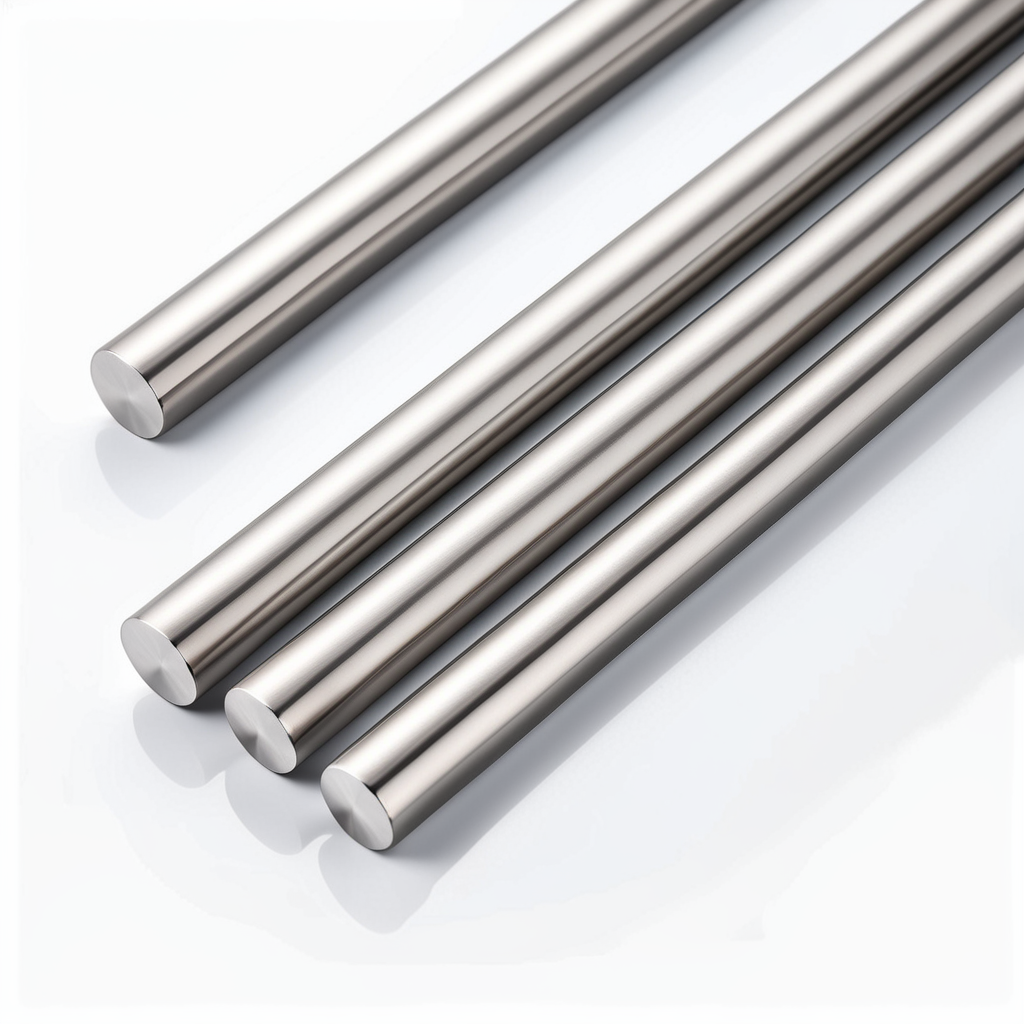

Why Choose Tongyi Metal’s 303 Stainless Steel Bars?

If you need high-quality 303 stainless steel bars, Tongyi Metal is your best option. Our 303 stainless steel bars are easy to machine and perfect for precise work. We also offer customization options to meet your specific needs, including size, hardness, and other factors. Whether you’re working on automotive parts or need stainless steel for medical devices, Tongyi Metal has you covered.

Our products are of excellent quality, delivered on time, and offer great value for money.

In short, machining 303 stainless steel is a fairly simple task, but it’s important to pay attention to details like tool selection, cutting speed, and cooling. By following the right techniques, you can achieve high-quality results.

If you need top-notch 303 stainless steel bars for your project, Tongyi Metal can provide you with the best products and services to help you complete your work smoothly.