In recent years, the rapid development of the automotive industry has significantly expanded the application of steel, leading to increased market demand and a rise in the consumption of free cutting steel. As automotive technologies evolve, the importance of fastener technology in China has become a key area of focus.

To meet the ever-increasing demands for safety, energy efficiency, noise reduction, and lower emissions in modern vehicles, the quality of fasteners is under greater scrutiny than ever before. This shift has prompted manufacturers to be more selective when choosing raw materials, with fastener technology advancing toward lighter weight, greater load-bearing capacity, and improved aesthetics.

Advancements in Fastener Technology

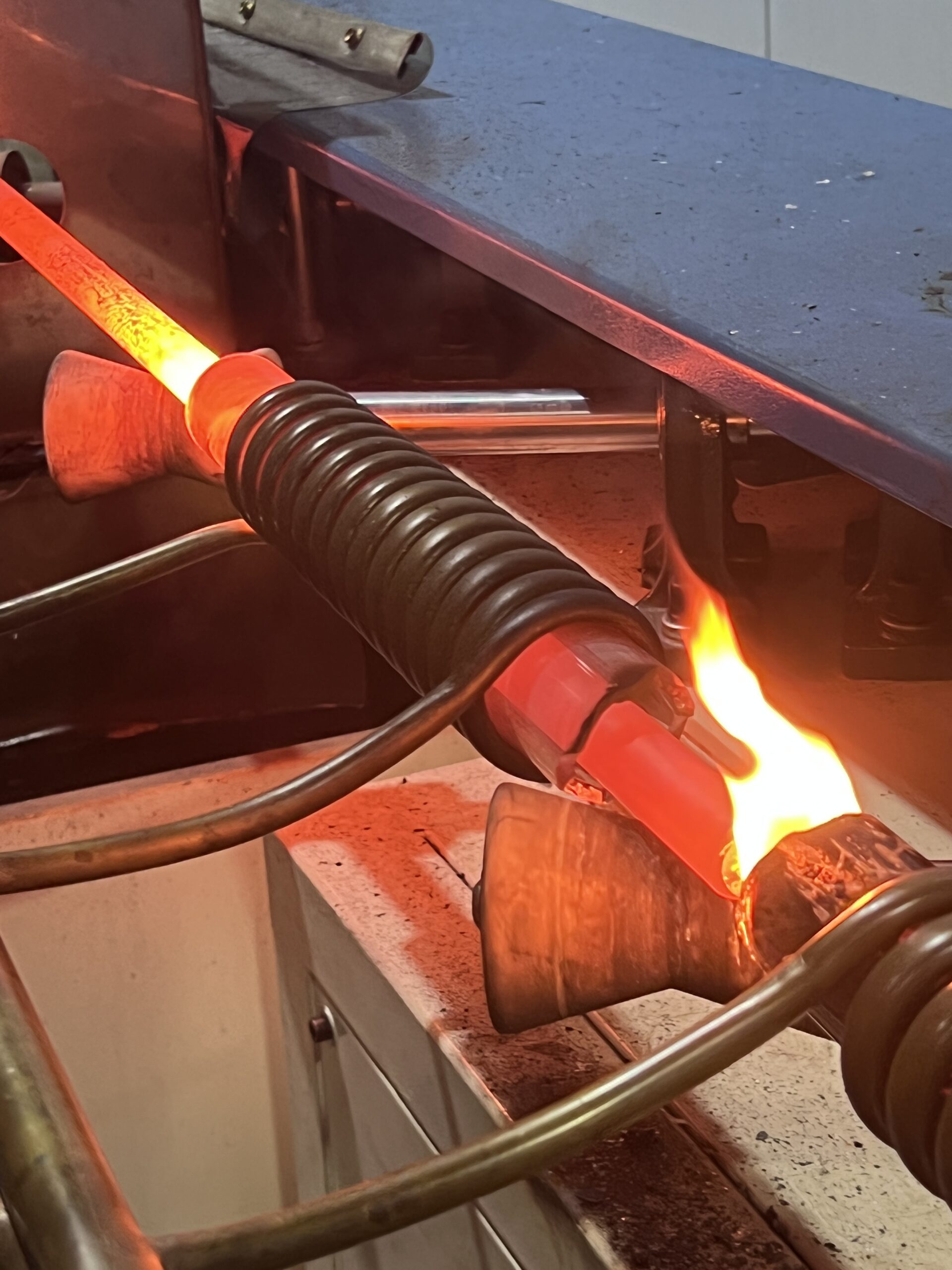

Threaded fasteners often undergo various strengthening treatments to enhance their load-bearing capabilities. After heat treatment, for example, the strength of these fasteners can increase by as much as 75%.

For threaded fasteners that require quenching and tempering, careful consideration must be given to the material’s hardenability. This ensures an adequate hardening depth or the use of a coolant with a slower cooling rate, which can minimize the risk of quenching-related cracks, residual stress, or deformation.

Fasteners that are machined require materials with good cutting performance to improve tool life and production efficiency. In these cases, free cutting steel is often the preferred choice.

Increasing Demand for Free Cutting Steel

With the rapid expansion of China’s automotive industry, the demand for free cutting steel continues to grow. Currently, free cutting steel accounts for about 2.1% of the total weight of a typical automobile, making it the third most-used automotive steel after carbon steel (5.8%) and alloy steel (3.7%).

At present, China’s annual demand for free cutting steel in the automotive sector is approximately 100,000 tons (excluding agricultural machinery and tractors). This is still significantly behind Japan, where the demand reaches around 1 million tons per year. These figures highlight the potential for further growth in China’s free cutting steel market.

Key Applications of Free Cutting Steel in Automobiles

Free cutting steel is widely used in the production of numerous automotive components, such as:

- Crankshafts

- Connecting rods

- Supporting rods

- Steering bars

- Running parts

- Washers

- Flanges

- Gear brakes

- Shafts

- Racks

- Spark plugs

As the automotive industry in China continues to grow, the role of free cutting steel will become increasingly important, driving further advancements in fastener technology and automotive manufacturing.