Does Stainless Steel Rust? Tongyi Metal Explains Everything

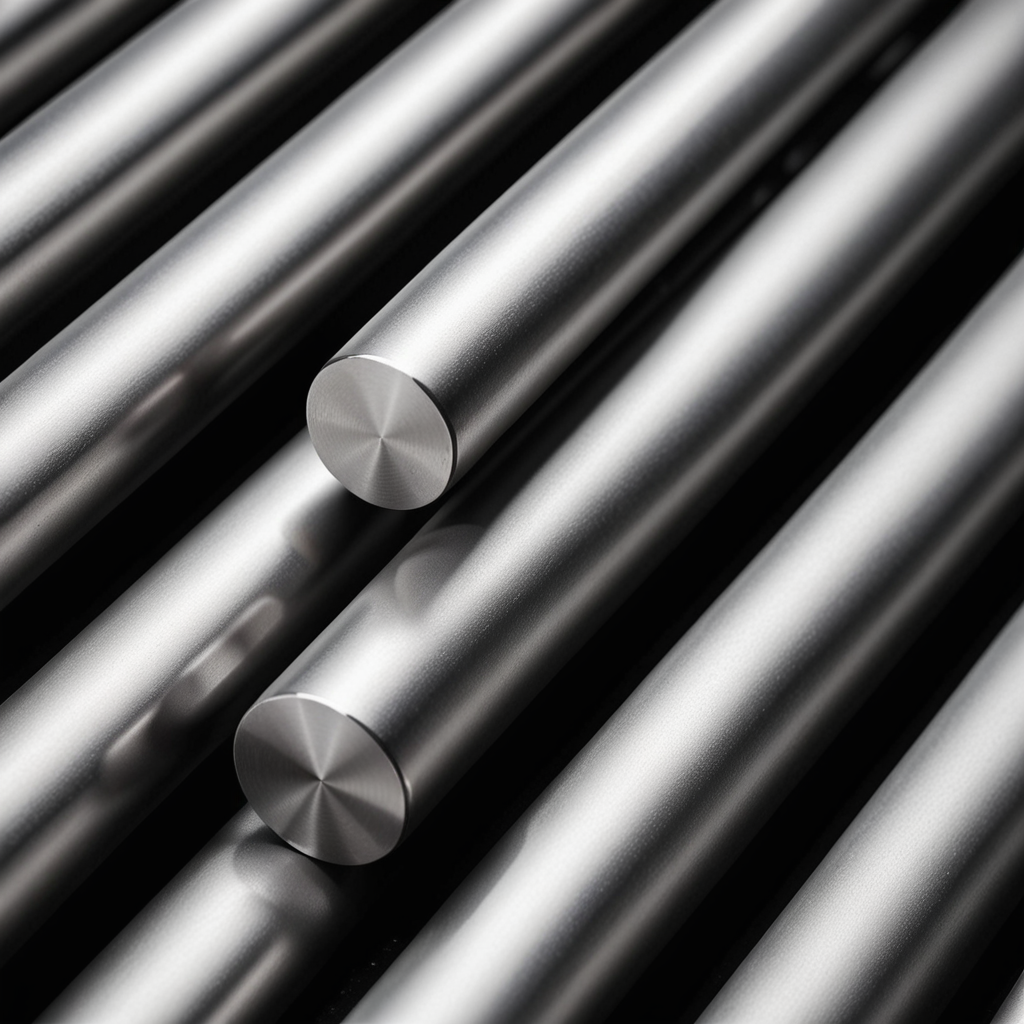

As a professional stainless steel rod manufacturer, Tongyi Metal often gets asked one common question: Does stainless steel rust?

While stainless steel is renowned for its excellent corrosion resistance, it’s not completely immune to rust. Under certain conditions, even stainless steel rods can develop rust spots. This article explores why stainless steel can rust, the factors that cause it, and how to prevent stainless steel rods from rusting to extend their lifespan.

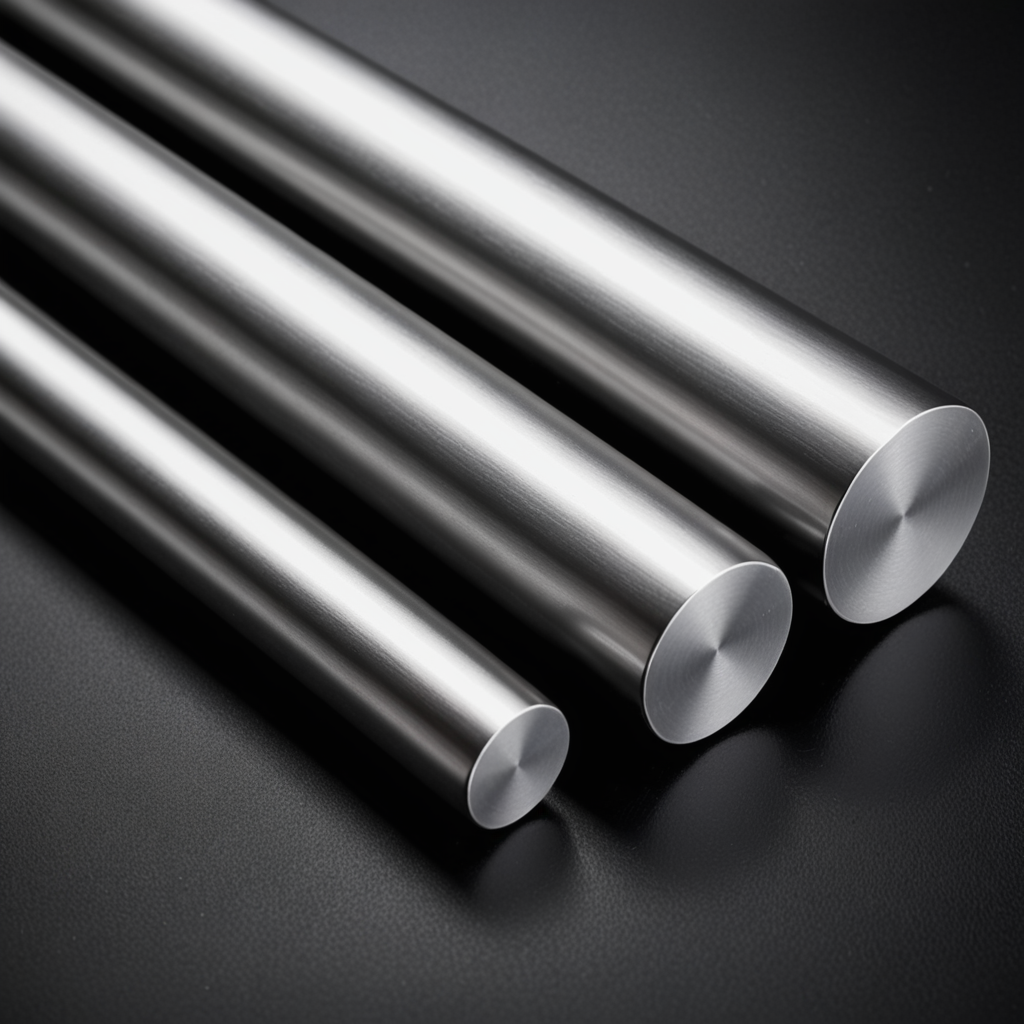

What is Stainless Steel?

Stainless steel is an alloy primarily composed of iron, chromium, and other elements such as nickel and molybdenum. Its rust resistance comes from chromium, which reacts with oxygen to form a thin, protective chromium oxide layer on the surface. This layer shields the iron beneath from further oxidation, preventing rust.

However, in specific environments, the protective layer can be compromised, causing rust spots to appear on stainless steel rods.

Why Do Stainless Steel Rods Rust?

Tongyi Metal summarizes the following common reasons why stainless steel rods may rust:

1. Environmental Factors

- High Humidity or Saltwater Exposure: In marine environments, salt can corrode the protective chromium oxide layer, especially on 304 stainless steel rods, making them prone to pitting.

- Chemical Corrosion: Acidic substances or chloride-based cleaners can damage the protective layer, leading to localized rusting.

2. Incorrect Material Selection

Lower-grade stainless steel rods, such as 430, contain less chromium and are less resistant to corrosion compared to 316 stainless steel rods. Choosing the wrong material can accelerate rusting in corrosive environments.

3. Surface Damage

Scratches or residual iron particles can damage the surface integrity of stainless steel rods, increasing the risk of rust formation.

4. Contamination or Improper Cleaning

External steel particles or uncleaned chemical residues can adhere to the stainless steel rod’s surface, leading to localized corrosion.

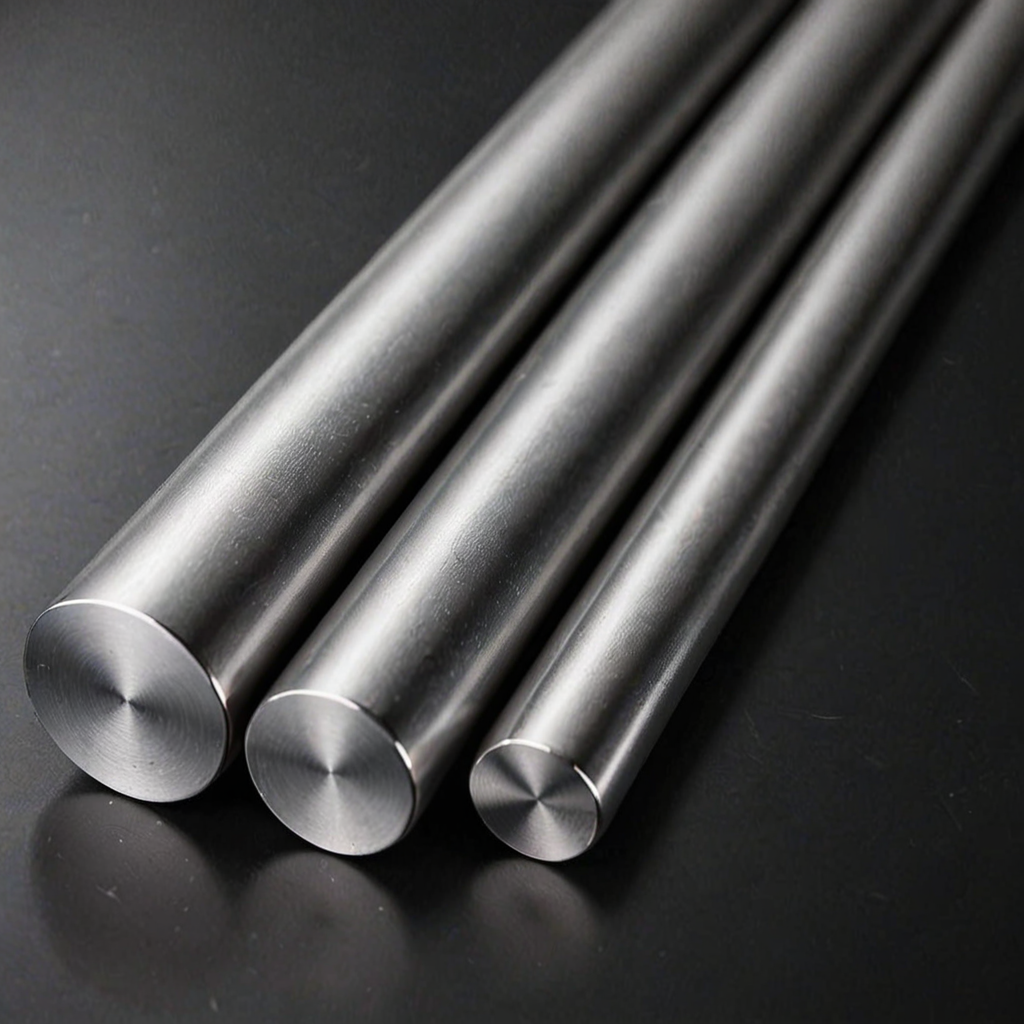

Which Stainless Steel Rods are More Rust-Resistant?

Tongyi Metal produces stainless steel rods in various grades. Below is a comparison of their rust resistance:

- 304 Stainless Steel Rods: Suitable for general industrial and household environments. They offer good corrosion resistance but may rust in high-salinity or acidic conditions.

- 316 Stainless Steel Rods: Enhanced with molybdenum, they provide superior resistance to saltwater corrosion, making them ideal for marine and chemical environments.

- 430 Stainless Steel Rods: A budget-friendly option with lower corrosion resistance, suitable for dry environments or applications with lower rust resistance requirements.

How to Prevent Stainless Steel Rods from Rusting

To ensure the performance and appearance of stainless steel rods, Tongyi Metal recommends the following measures:

1. Choose the Right Stainless Steel Rod Grade

Select a grade suitable for your application. For example, use 316 stainless steel rods in marine or highly corrosive environments.

2. Regular Cleaning

- Clean stainless steel rods with mild detergent and water regularly.

- Avoid using abrasive cleaning tools or products containing chlorine to prevent scratching the surface.

3. Optimize Storage Conditions

Store stainless steel rods in a dry, ventilated environment to minimize exposure to moisture.

4. Surface Passivation

Apply passivation treatments to enhance the protective layer on stainless steel rods and repair any damage to the oxide layer.

5. Prevent Contamination

Use dedicated tools and cleaning cloths for stainless steel rods to avoid contamination from other metals.

How to Remove Rust from Stainless Steel Rods

If rust spots appear on stainless steel rods, try the following methods:

- Baking Soda Paste: Mix baking soda with water to create a paste. Gently scrub the rust spots and rinse thoroughly.

- White Vinegar: Apply white vinegar to the rust spots using a soft cloth, let it sit briefly, and then rinse clean.

- Commercial Rust Removers: Use rust removers specifically designed for stainless steel and follow the instructions carefully.

Do All Stainless Steel Rods Rust?

Not all stainless steel rods are equally prone to rust. High-grade stainless steel rods, like 316, perform exceptionally well even in harsh environments. However, under extreme conditions, any stainless steel can show signs of corrosion. Therefore, selecting the appropriate grade and taking preventive measures are crucial.

Why Choose Tongyi Metal for Your Stainless Steel Rods?

As an experienced stainless steel rod manufacturer, Tongyi Metal is committed to delivering high-quality and durable stainless steel rods. We recommend the best stainless steel grade for your specific application and provide professional rust prevention solutions.

Whether you need stainless steel rods for food processing, architectural decoration, or marine engineering, Tongyi Metal offers top-quality products and tailored solutions to meet your needs.

Conclusion

While stainless steel rods are known for their excellent corrosion resistance, they can still rust under certain conditions. Understanding the causes of rust and implementing proper maintenance can significantly extend the lifespan of stainless steel rods.

If you have any questions about stainless steel rods or need a quote, feel free to contact Tongyi Metal. We are here to provide expert advice and high-quality products to meet all your requirements!