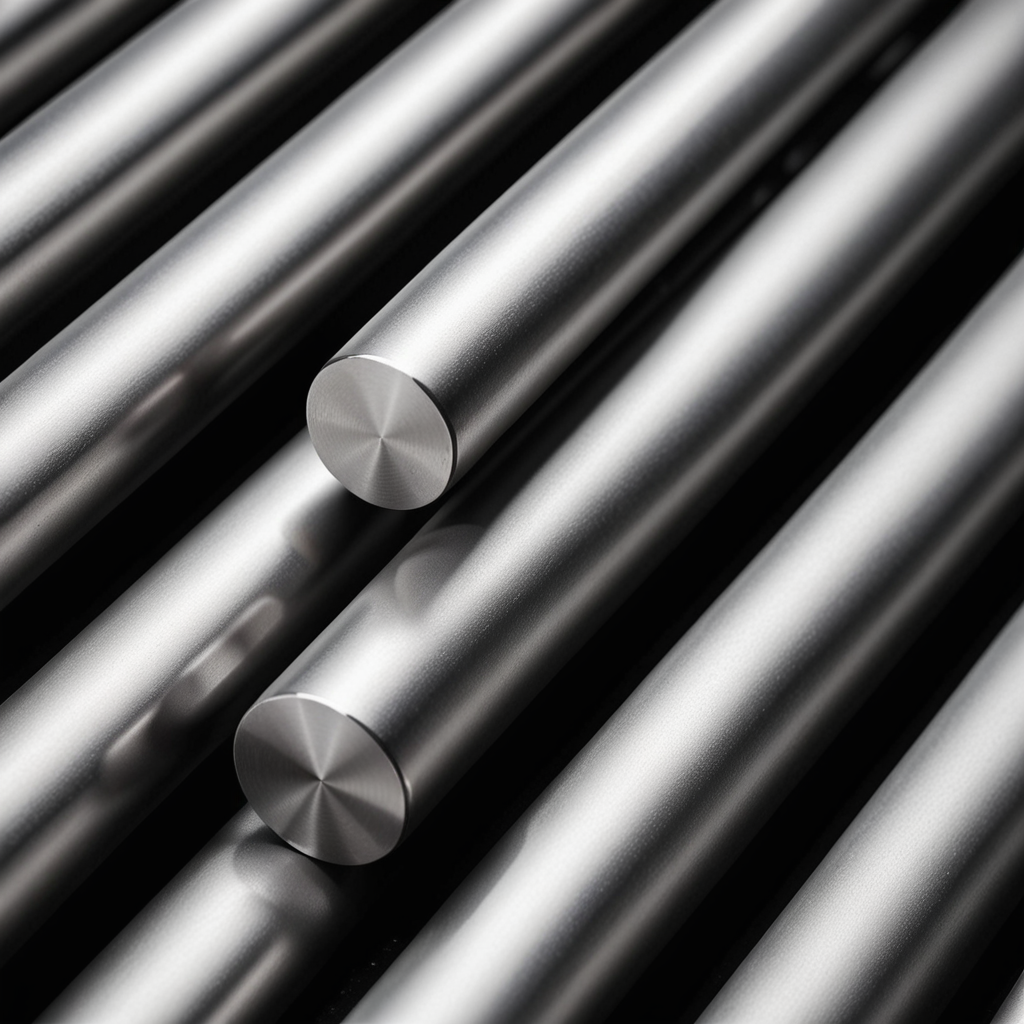

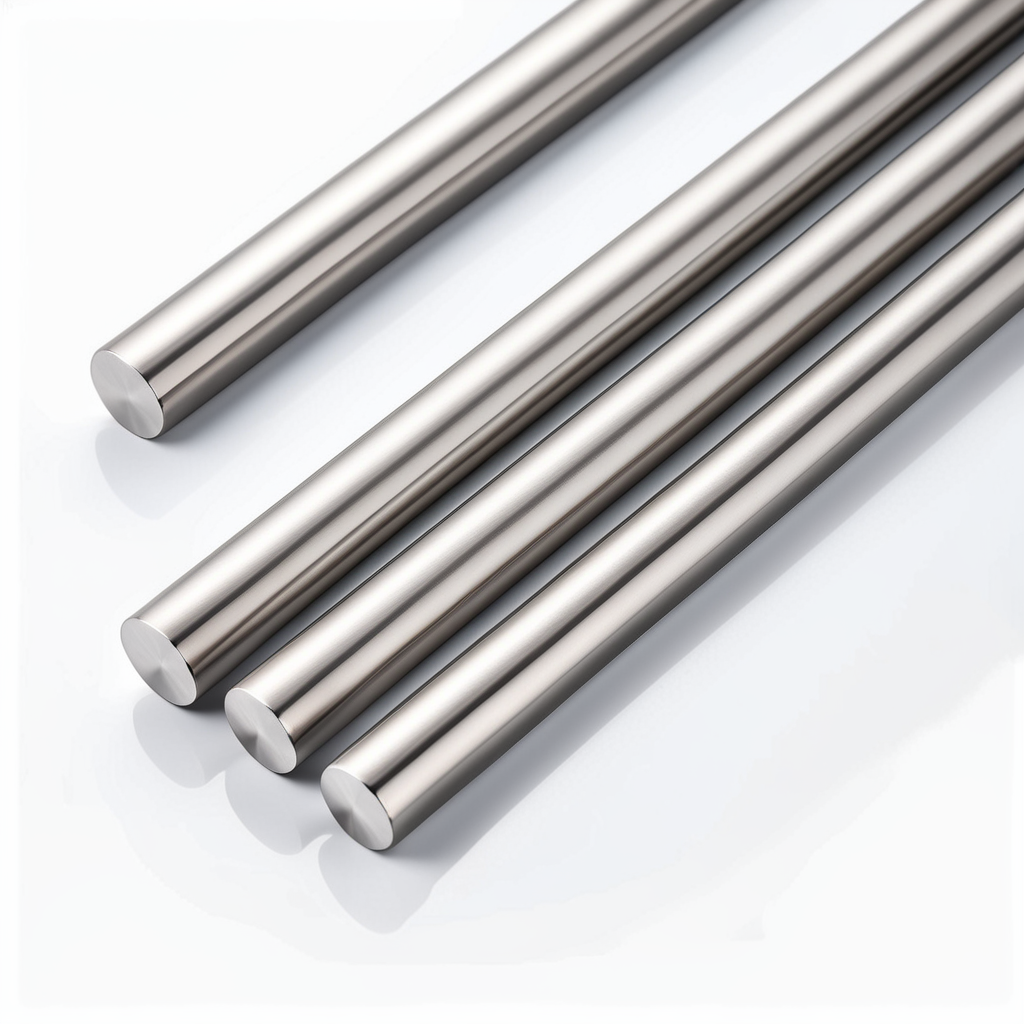

With advancements in technology, high-precision titanium alloy rods have become an essential material in the medical industry. Their unique properties make them indispensable in various medical devices and implants. In this article, we will explore the specific applications of titanium alloy rods in the medical field and why this material is so crucial in healthcare.

Superior Properties of Titanium Alloys

Titanium alloys are known for their high strength, low density, corrosion resistance, and excellent biocompatibility with the human body. These attributes make titanium alloy rods ideal for use in medical devices and implants that require long-term contact with human tissues.

Compared to traditional metal materials, titanium alloy rods offer better fatigue resistance, meaning they can withstand high pressure and stress environments for long periods. This makes titanium alloys widely used in surgical instruments, joint replacements, and orthopedic implants.

Applications of High-Precision Titanium Alloy Rods in the Medical Field

- Orthopedic Implants

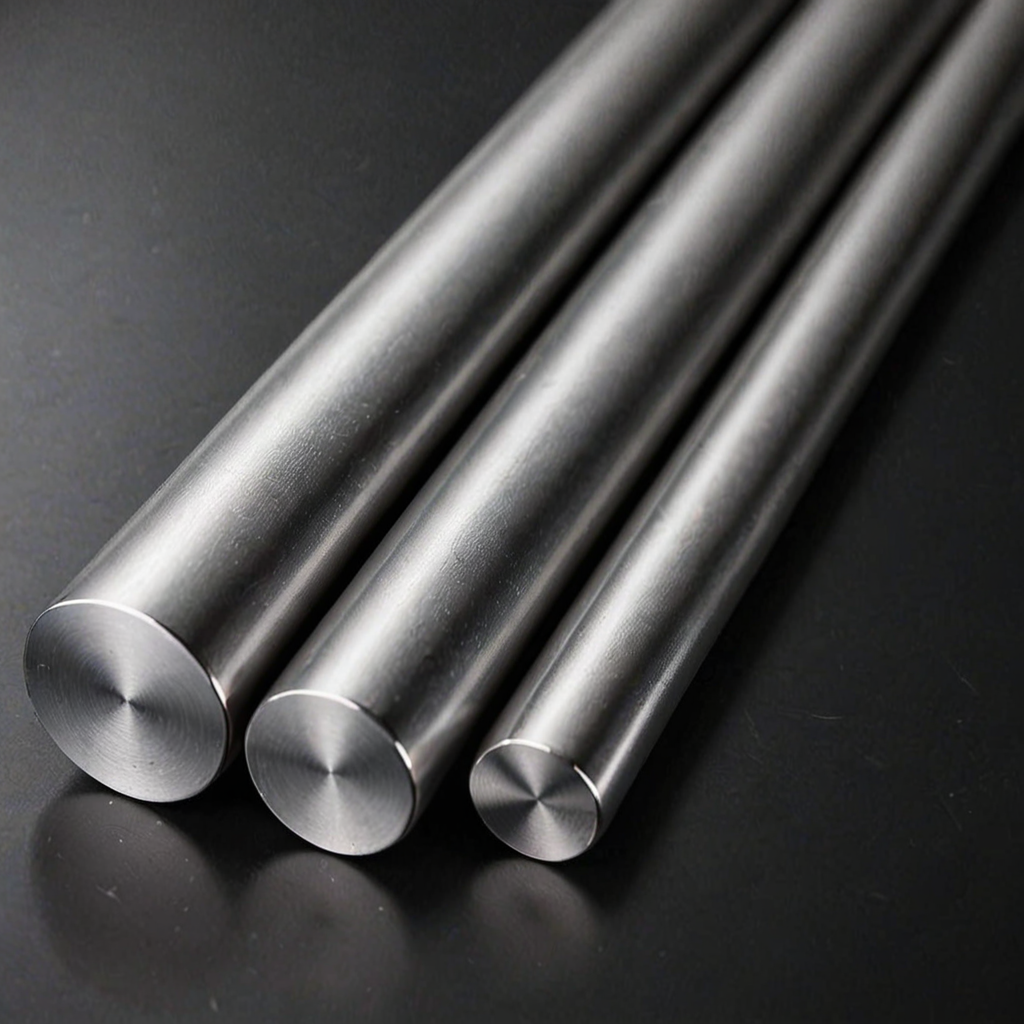

In orthopedic surgeries, titanium alloy rods are used to make bone screws, plates, and other implants. Due to the biocompatibility of titanium alloys, they integrate well with human bones, promoting faster recovery for patients. The high strength and lightweight properties of titanium alloy rods ensure that the implants remain stable under pressure, reducing the risk of post-surgery complications. - Joint Replacement Surgery

Titanium alloys are among the top choices for manufacturing artificial joints. Their wear resistance and low density enable patients to maintain mobility without discomfort from the weight of the implants. Additionally, the corrosion resistance of titanium alloys ensures that the joint implants remain in good condition for extended periods, significantly increasing their lifespan. - Dental Implants

In dentistry, titanium alloy rods are commonly used for dental implants. They not only offer excellent mechanical properties but also fuse well with the jawbone, enhancing the stability and durability of the implant. The corrosion resistance of titanium ensures that the implant performs well in the oral environment, reducing the risk of infection or implant failure. - Surgical Instruments

Many high-precision surgical tools such as scalpels and surgical scissors are made from titanium alloy rods. Titanium alloys are lightweight, durable, and reduce the risk of adverse reactions during surgery. Additionally, these tools are easy to sterilize and can be reused, improving cost-efficiency for medical institutions.

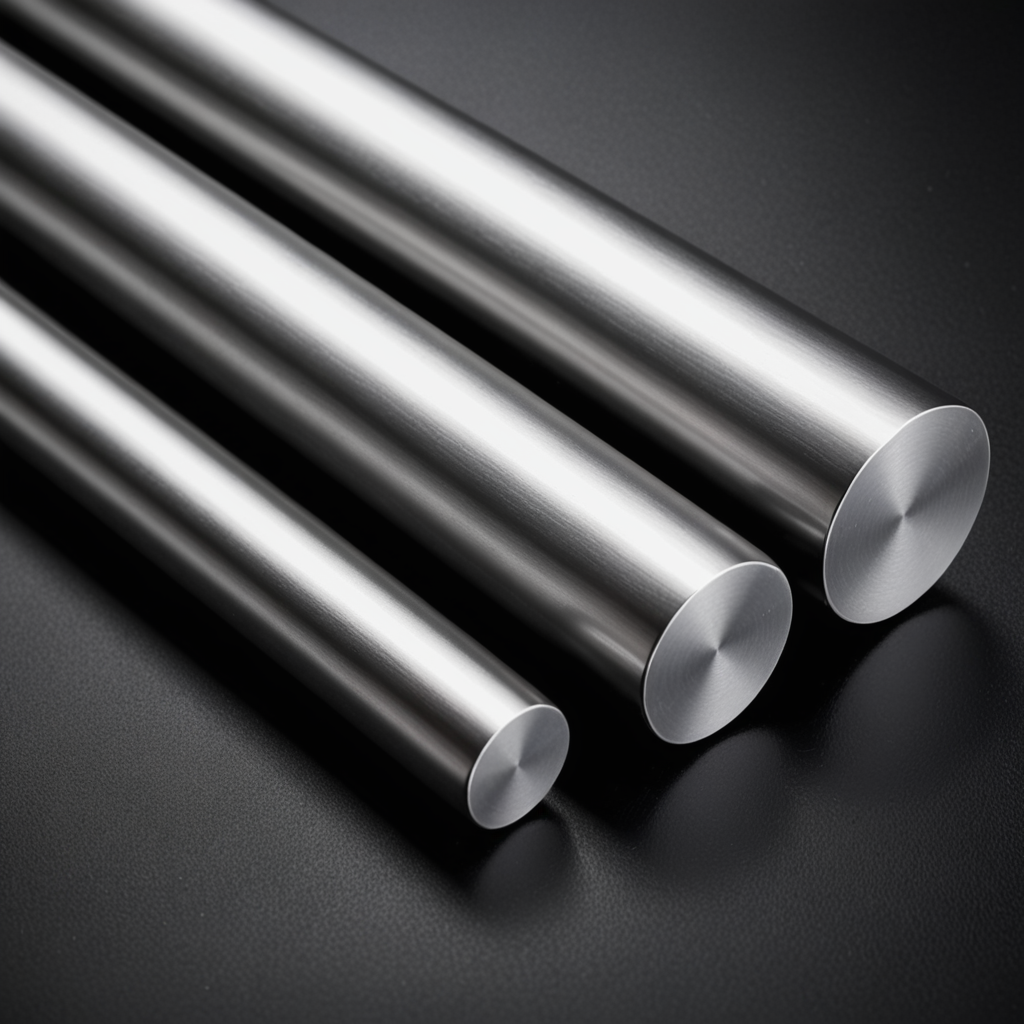

Why Choose High-Precision Titanium Alloy Rods?

- Exceptional Biocompatibility

Titanium alloys are known for their excellent biocompatibility, allowing them to interact with human tissue without triggering rejection. This makes them an ideal material for long-term implants like artificial joints and dental implants. - High Strength and Low Density

Titanium alloy rods offer the perfect combination of strength and lightweight properties, making them suitable for medical devices that need to withstand high pressure over long periods. Their lightweight nature reduces the burden on patients while still providing the necessary support for bones and joints. - Corrosion and Wear Resistance

Whether used inside the body or in external environments, titanium alloys exhibit strong corrosion resistance, able to withstand exposure to bodily fluids and external elements. This significantly enhances the lifespan of implants and medical devices. Additionally, their wear resistance ensures they do not deteriorate quickly, even with prolonged use. - Precision Machinability

Titanium alloy rods can be precisely manufactured using advanced CNC machining technologies, allowing for the creation of complex medical components. The high precision not only ensures the quality of the device but also enhances patient comfort and the success rate of medical procedures.

Future Outlook: Titanium Alloy in the Medical Industry

As medical technology continues to advance, the demand for materials with enhanced properties will increase. With its exceptional characteristics, titanium alloys will continue to play a significant role in the medical industry. From more intricate implant designs to advanced surgical instruments, high-precision titanium alloy rods have the potential to meet the growing demands of the healthcare sector.

Additionally, with ongoing research and development into new titanium alloys, the scope of their applications will expand further, offering solutions to a wide range of medical challenges.

Conclusion

High-precision titanium alloy rods are now extensively used in various medical fields such as orthopedic implants, joint replacements, dental implants, and surgical instruments. Their biocompatibility, strength, corrosion resistance, and precision machinability make them an ideal choice in the medical industry. As the demand for more precise and durable medical devices grows, titanium alloys will play an increasingly important role in improving patient outcomes.

If you’re looking for materials that can enhance the quality of medical devices, high-precision titanium alloy rods are undoubtedly a reliable choice. Whether in design or production, titanium alloys provide unparalleled performance for your products.