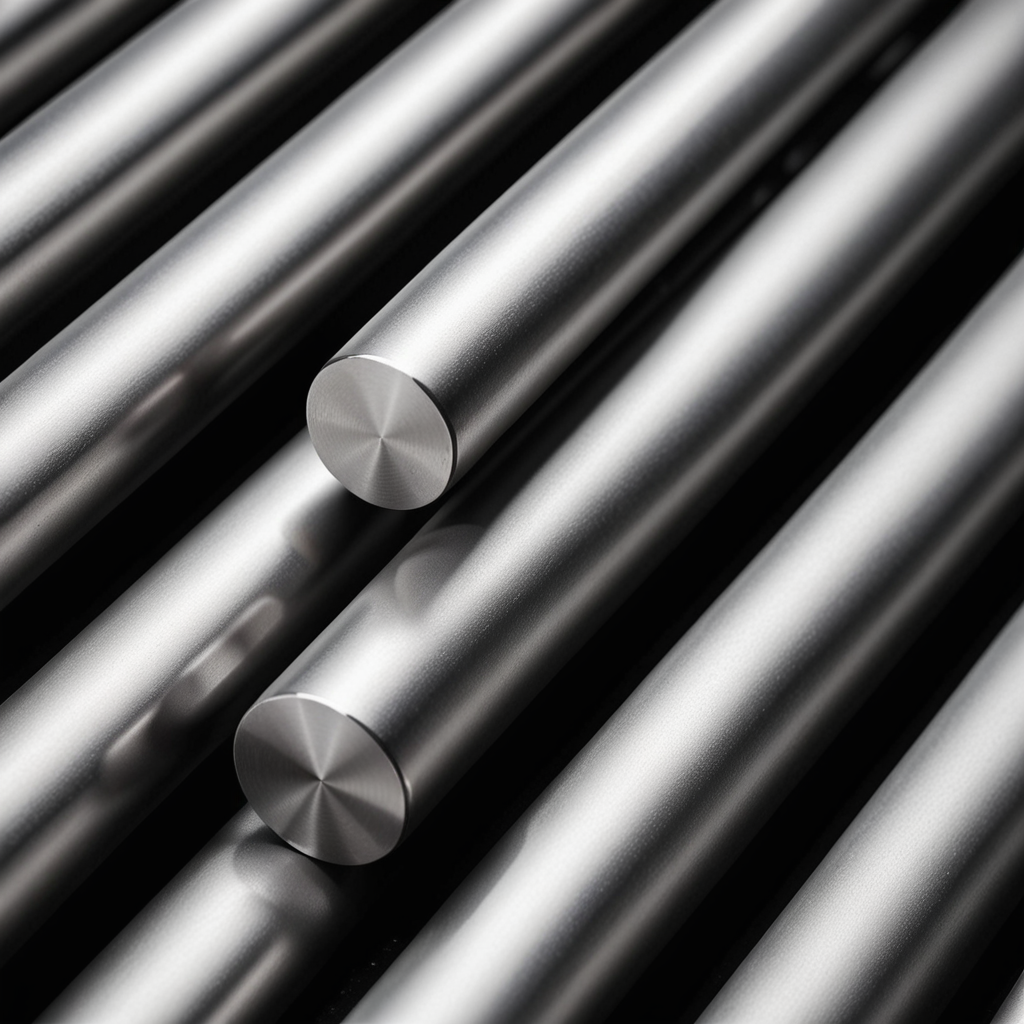

Stainless steel rods are used across various industries due to their strength, corrosion resistance, and versatility. However, selecting the right stainless steel rod depends on factors like the operating environment, required strength, and machinability. This guide will help you understand how to choose the best stainless steel rod for your specific industry needs.

Factors to Consider When Choosing a Stainless Steel Rod

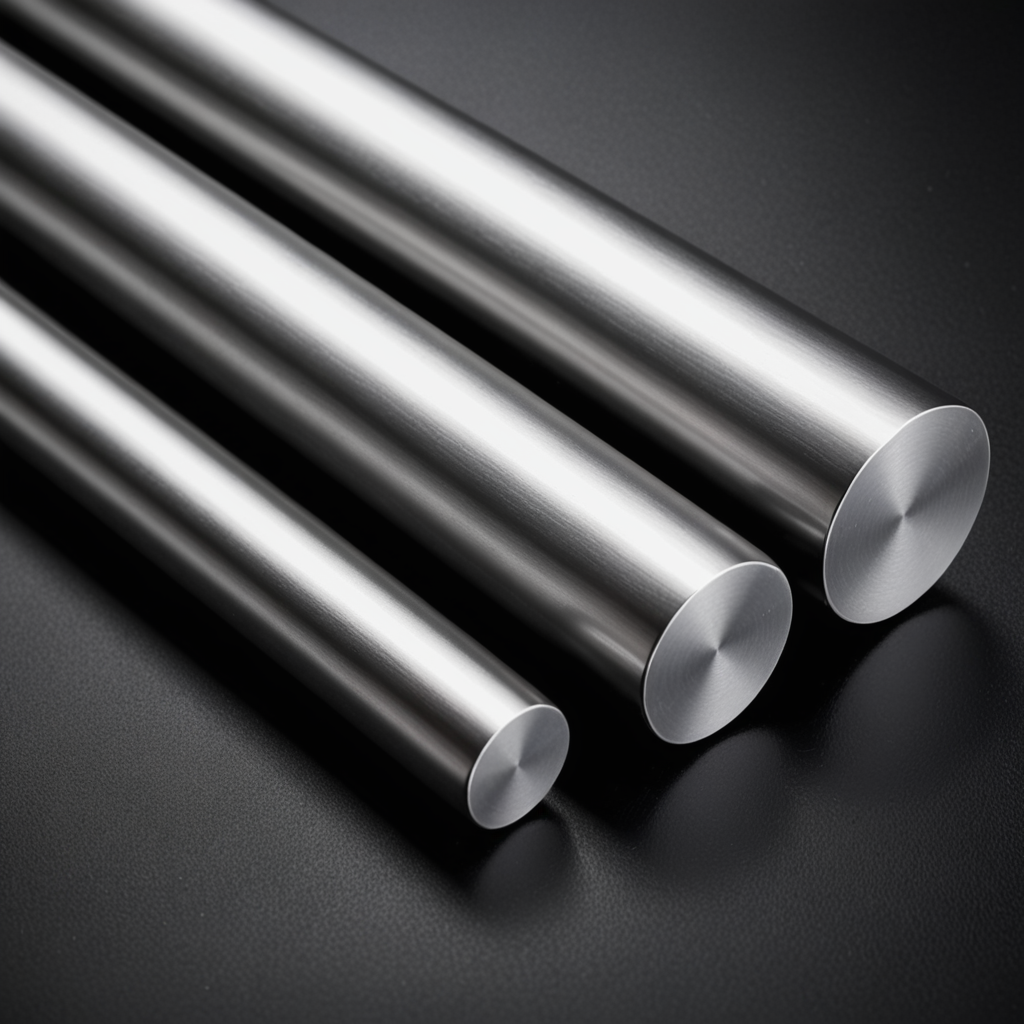

- Corrosion Resistance – Essential for environments exposed to moisture, chemicals, or saltwater.

- Strength & Durability – High-strength rods are needed for heavy-duty applications.

- Machinability – Some grades are easier to cut and shape, reducing production costs.

- Temperature Resistance – Important for industries with extreme heat exposure.

Comparison of Stainless Steel Rod Grades

| Grade | Corrosion Resistance | Strength | Machinability | Best Applications |

|---|---|---|---|---|

| 303 | Moderate | Medium | Excellent | Precision machining, fasteners |

| 304 | High | High | Good | Food processing, medical, construction |

| 316 | Excellent | High | Moderate | Marine, chemical, and medical industries |

| 410 | Moderate | Very High | Fair | Automotive, industrial tools |

| 420 | Moderate | Very High | Low | Cutlery, surgical instruments |

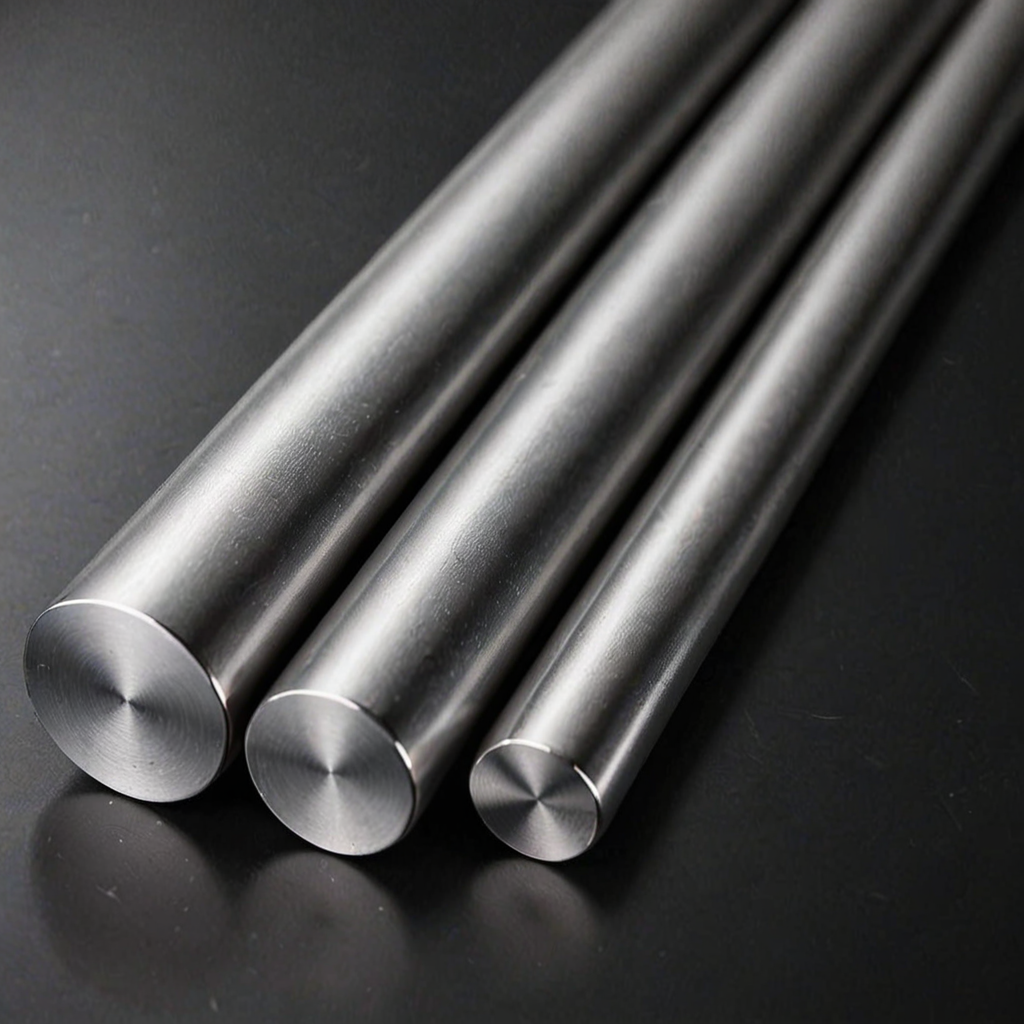

Best Stainless Steel Rods for Different Industries

- Aerospace Industry – 316 stainless steel for high strength and corrosion resistance.

- Automotive Industry – 410 stainless steel for durability and wear resistance.

- Medical Industry – 304 and 316 stainless steel for biocompatibility and sterilization safety.

- Food Processing Industry – 304 stainless steel for hygiene and corrosion resistance.

- Marine Industry – 316 stainless steel for superior saltwater resistance.

Choosing the right stainless steel rod depends on your industry’s specific requirements. Whether you need high corrosion resistance, superior strength, or excellent machinability, selecting the right grade ensures optimal performance and longevity. Evaluate your needs carefully to make the best choice for your application.