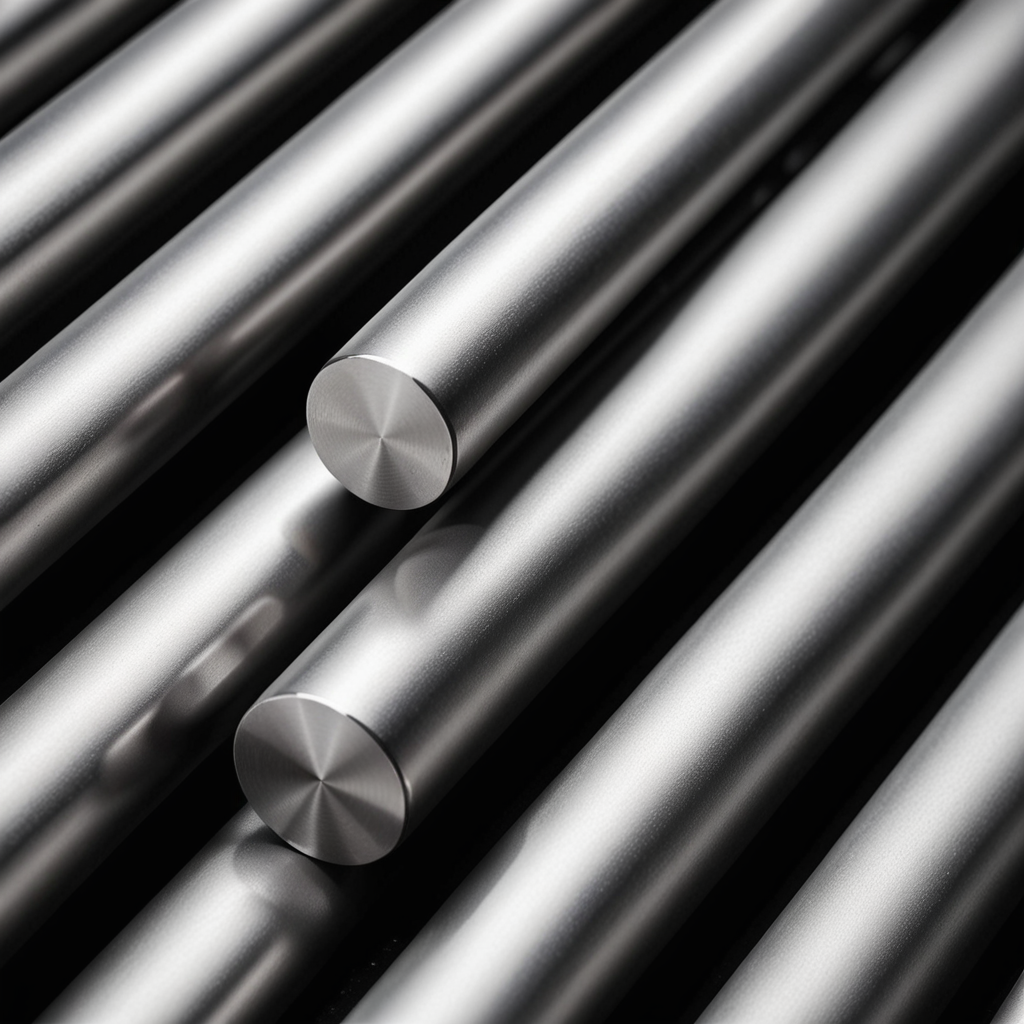

Stainless steel rods are widely used across different industries due to their excellent strength, corrosion resistance, and durability. From aerospace to medical manufacturing, these rods play a crucial role in ensuring high performance and reliability. This article explores the most common applications of stainless steel rods in various fields.

Why Use Stainless Steel Rods?

Stainless steel rods offer several advantages:

- Corrosion Resistance – Ideal for harsh environments, preventing rust and degradation.

- High Strength – Suitable for heavy-duty applications requiring durability.

- Excellent Machinability – Some grades allow easy shaping and forming.

- Heat Resistance – Performs well in high-temperature environments.

Industry-Wise Applications of Stainless Steel Rods

| Industry | Application | Why Stainless Steel? |

|---|---|---|

| Aerospace | Aircraft components, landing gear | High strength, lightweight, and corrosion resistance |

| Automotive | Engine parts, exhaust systems | Heat resistance and durability under extreme conditions |

| Medical | Surgical instruments, orthopedic implants | Biocompatibility, sterilization resistance, and strength |

| Food Processing | Equipment, conveyor belts | Non-reactive, hygienic, and easy to clean |

| Marine | Shipbuilding, offshore structures | Excellent resistance to saltwater corrosion |

| Construction | Structural reinforcements, bridges | Strength, weather resistance, and longevity |

| Electronics | Connectors, precision components | Electrical conductivity and machinability |

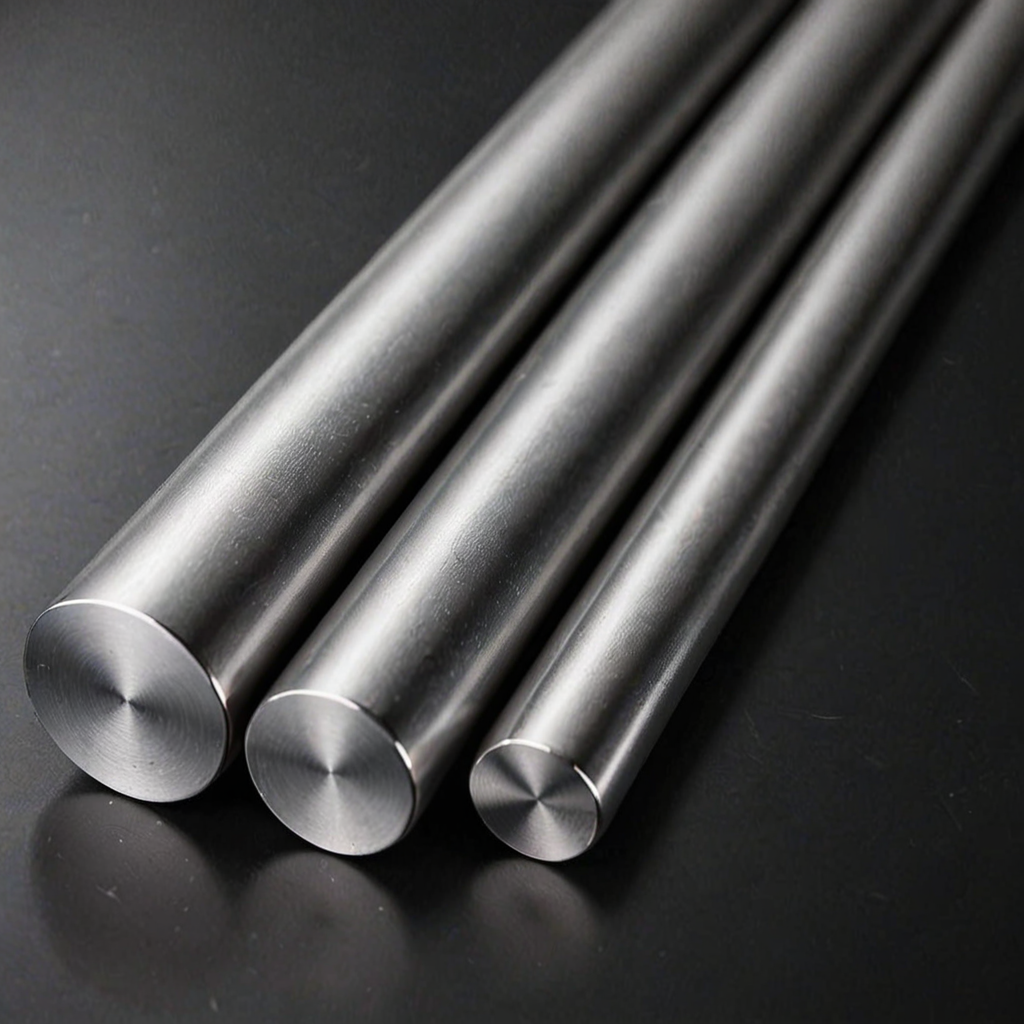

Choosing the Right Stainless Steel Rod

Selecting the right stainless steel rod depends on the application. For high machinability, 303 stainless steel is ideal, while 304 stainless steel offers better corrosion resistance. 316 stainless steel is perfect for marine applications due to its superior saltwater resistance.

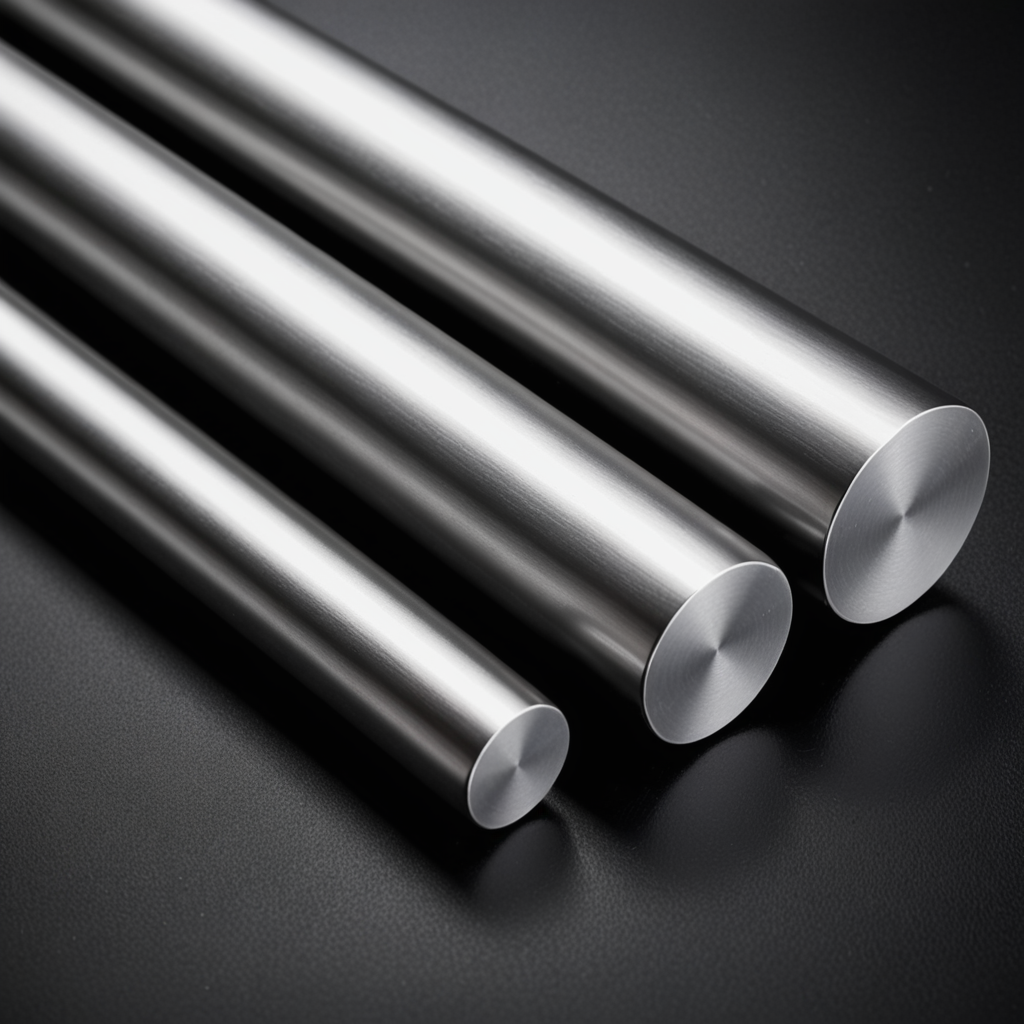

Stainless steel rods are essential in many industries, providing strength, corrosion resistance, and reliability. Whether used in aerospace, medical, or construction, they enhance performance and longevity. Choosing the right grade ensures optimal results for your specific needs.