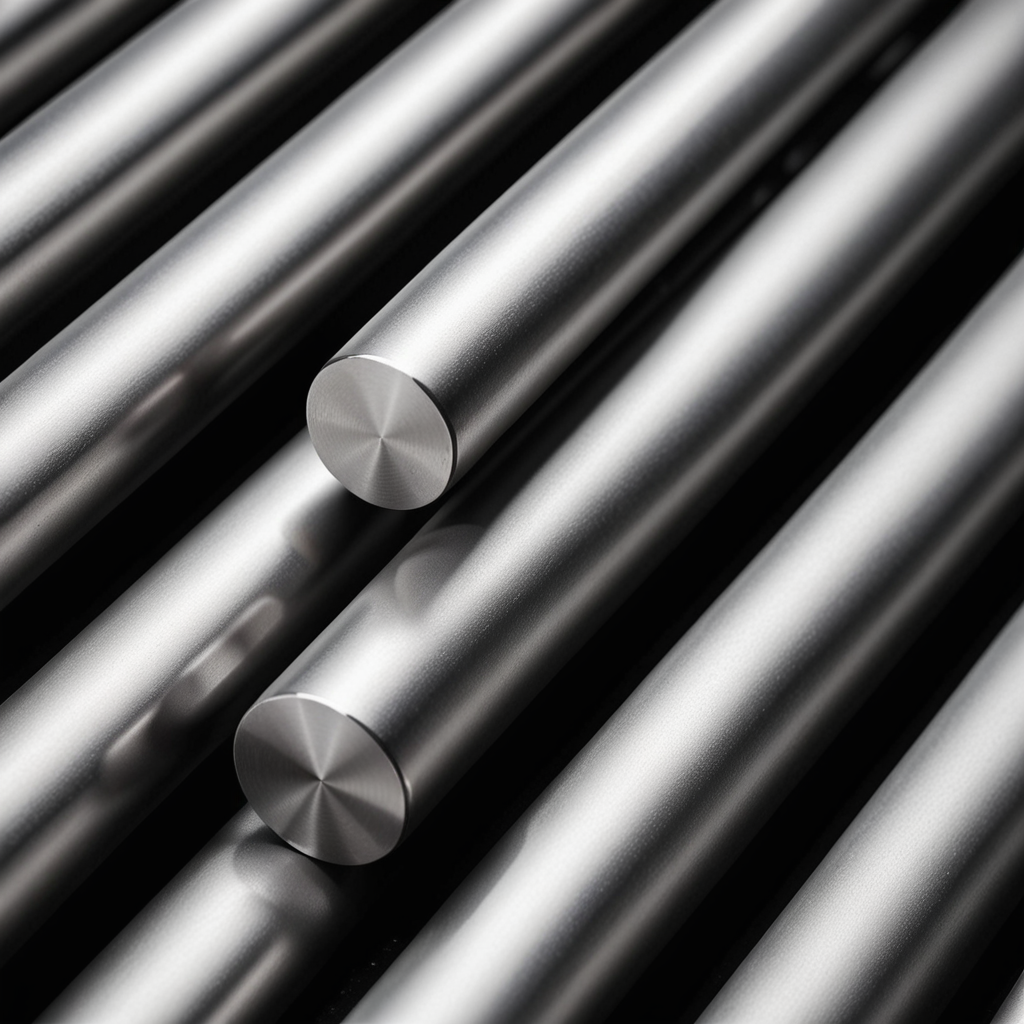

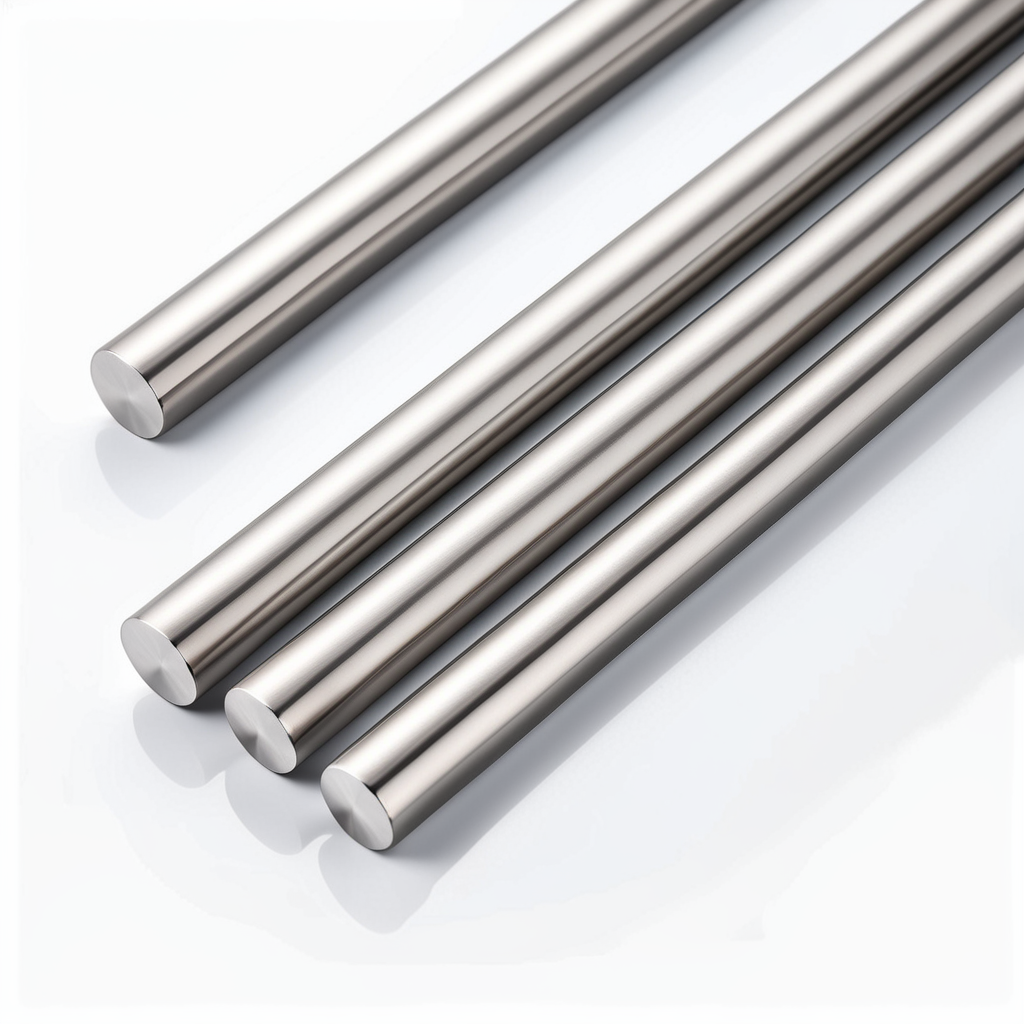

Selecting the right material is key to manufacturing success. 303 stainless steel bars offer excellent machinability, corrosion resistance, and durability, making them a top choice for precision machining. In this article, we’ll explore how 303 stainless steel bars enhance both product quality and production efficiency.

Why 303 Stainless Steel Bars?

303 stainless steel bars contain sulfur, improving their machinability compared to other stainless steel grades. This feature makes them ideal for applications requiring intricate details and smooth finishes. They also resist corrosion, ensuring long-lasting performance in various environments.

Benefits of 303 Stainless Steel Bars

| Feature | Benefit |

|---|---|

| Superior Machinability | Reduces tool wear, increases cutting speed, and lowers production costs. |

| Corrosion Resistance | Ensures product longevity, even in harsh environments. |

| High Surface Finish | Produces smooth, precise components with minimal post-processing. |

| Consistent Performance | Improves production stability and reduces material waste. |

How 303 Stainless Steel Enhances Quality & Efficiency

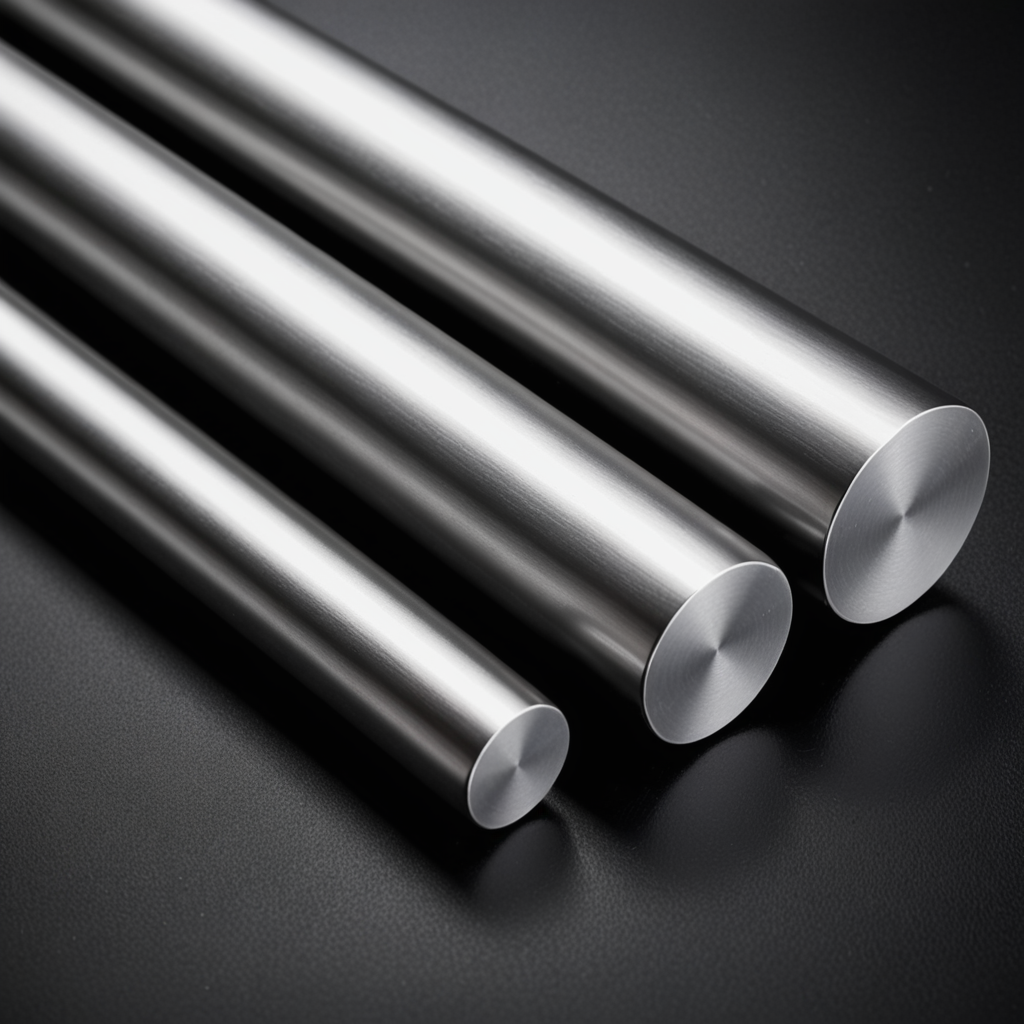

1. Faster Machining, Lower Costs

The high sulfur content in 303 stainless steel reduces cutting resistance. This allows for faster machining speeds, reducing cycle times and improving production rates. Manufacturers can complete more parts in less time, lowering overall costs.

2. Better Surface Finish, Higher Product Quality

303 stainless steel produces smoother surfaces, reducing the need for extensive finishing. This is crucial for precision components used in aerospace, automotive, and medical applications, where high accuracy is required.

3. Longer Tool Life, Less Downtime

Materials that wear down cutting tools quickly lead to frequent tool changes and increased downtime. 303 stainless steel’s machinability reduces tool wear, extending tool life and ensuring continuous production.

4. Enhanced Corrosion Resistance

Products made from 303 stainless steel last longer because they resist rust and oxidation. This reduces maintenance costs and enhances customer satisfaction by delivering durable, high-quality parts.

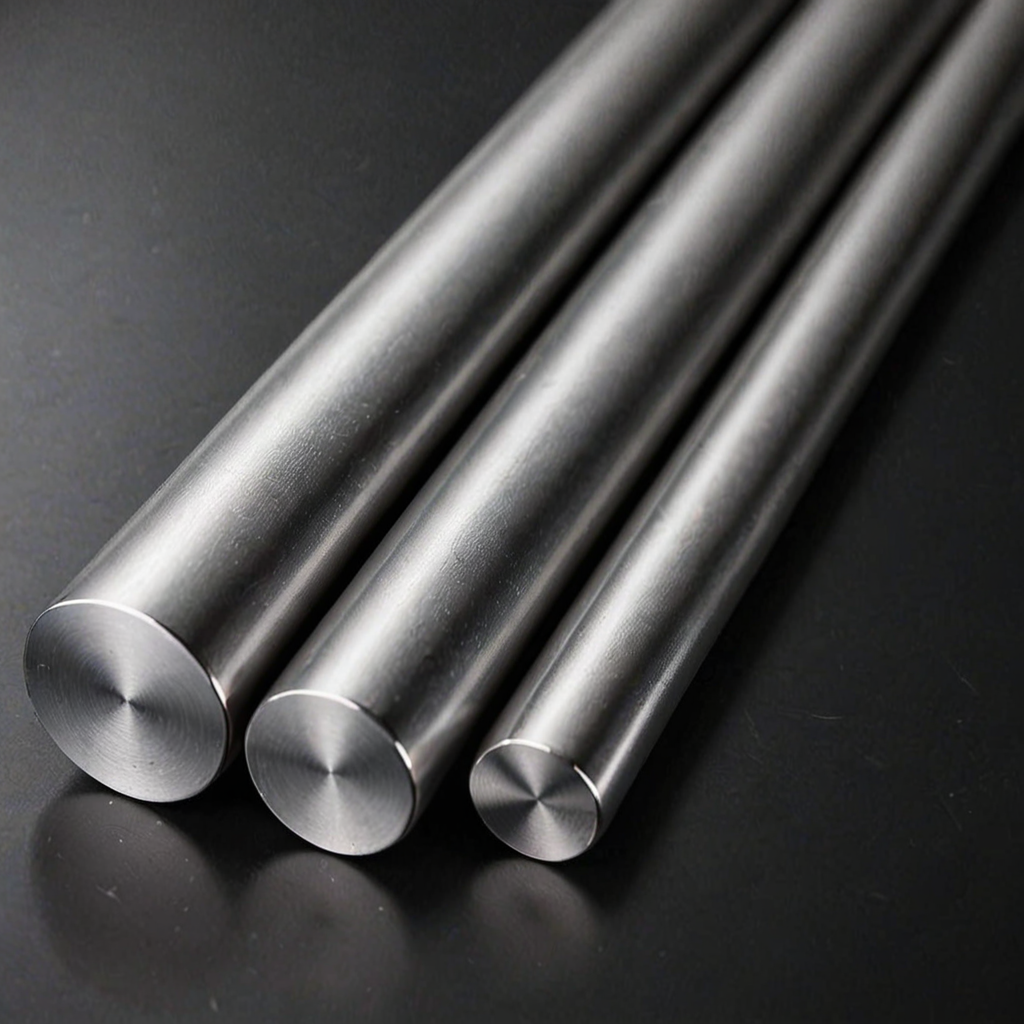

Applications of 303 Stainless Steel Bars

303 stainless steel bars are widely used in industries that require precision machining. Common applications include:

- Aerospace: High-precision fasteners and fittings.

- Automotive: Shafts, gears, and connectors.

- Medical: Surgical instruments and dental tools.

- Electronics: Connectors and precision components.

Using 303 stainless steel bars improves both production efficiency and product quality. Their superior machinability, corrosion resistance, and smooth surface finish make them a reliable choice for precision machining. If you’re looking for high-quality stainless steel bars, Tongyi Metal provides durable and cost-effective solutions tailored to your needs.