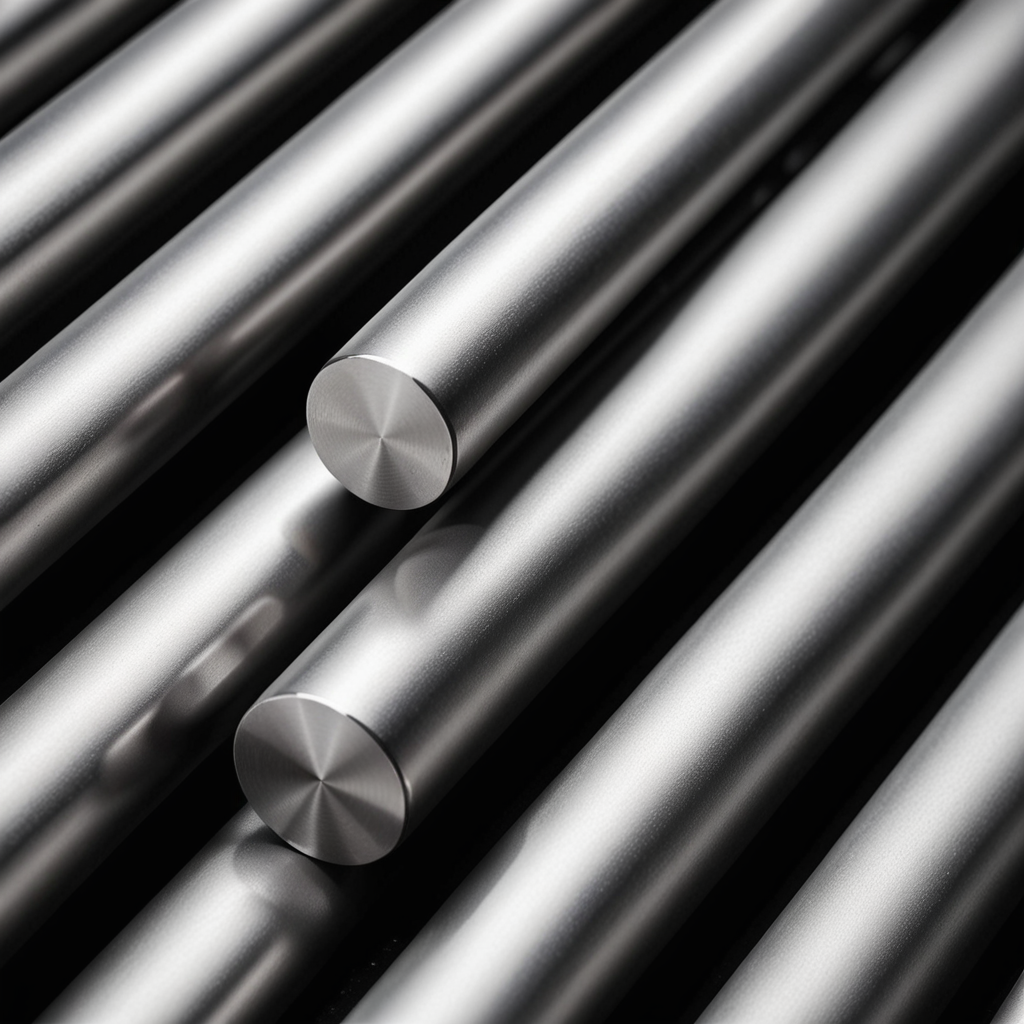

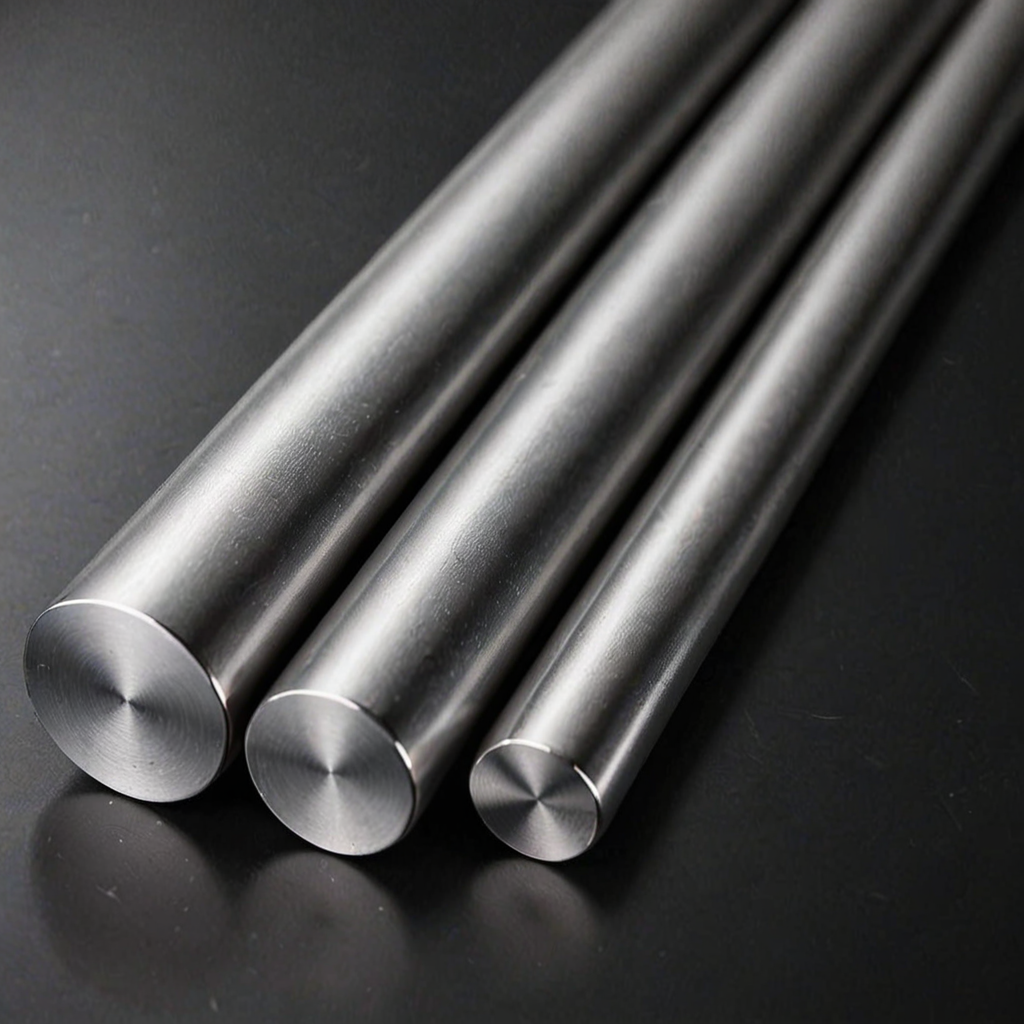

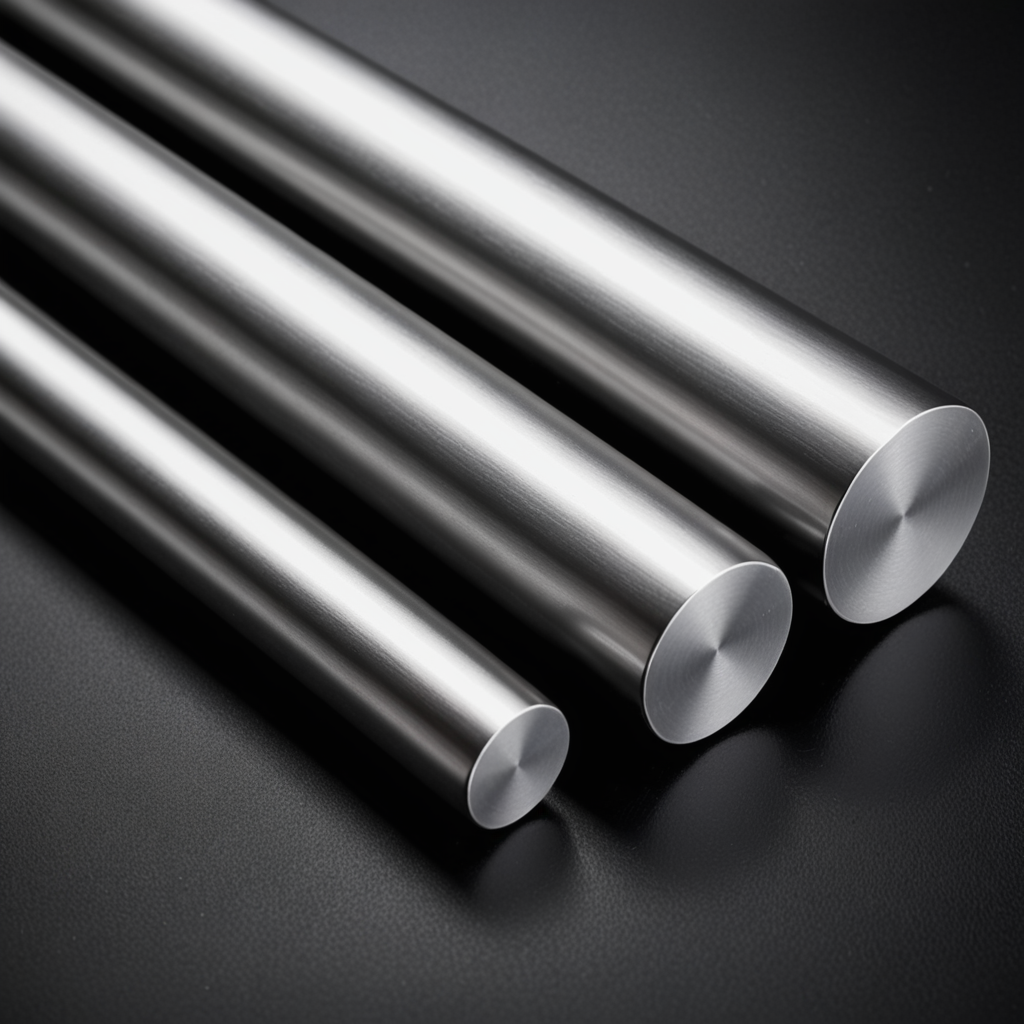

303 stainless steel bars are widely used in various industries due to their excellent machinability, corrosion resistance, and durability. They are ideal for precision machining and manufacturing components that require high accuracy. This article explores the properties of 303 stainless steel bars and their applications across different industries.

Key Characteristics of 303 Stainless Steel Bars

| Feature | Description |

|---|---|

| Machinability | Excellent due to sulfur content, ideal for CNC machining. |

| Corrosion Resistance | Good, but slightly lower than 304 stainless steel. |

| Strength & Hardness | High strength, but not as strong as 304. |

| Weldability | Limited due to sulfur content, requires special techniques. |

| Formability | Moderate, less flexible than 304 stainless steel. |

| Durability | Highly resistant to wear and mechanical stress. |

Applications of 303 Stainless Steel Bars in Different Industries

1. Precision Machining Industry

303 stainless steel is commonly used in CNC machining due to its excellent cutting performance. It allows manufacturers to produce complex and high-precision parts with minimal tool wear.

2. Automotive Industry

In the automotive sector, 303 stainless steel bars are used for fuel system components, sensors, and small precision parts. Their wear resistance and ease of machining make them ideal for such applications.

3. Aerospace Industry

303 stainless steel bars are utilized in aircraft fittings and fasteners, where precision and durability are crucial. Although 304 stainless steel is preferred for higher corrosion resistance, 303 is chosen when machining efficiency is the priority.

4. Medical Equipment Manufacturing

303 stainless steel is used in surgical instruments and medical tools. It provides high precision and durability, but for implantable medical devices, 304 or 316 stainless steel is preferred due to superior corrosion resistance.

5. Food Processing Equipment

Although 304 stainless steel is more common in food-grade applications, 303 stainless steel is still used for non-contact components that require precision machining.

6. Marine Industry

Due to its resistance to wear and corrosion, 303 stainless steel is used in marine fittings, fasteners, and non-critical structural components. However, 304 or 316 stainless steel is preferred in highly corrosive environments.

Why Choose 303 Stainless Steel from Tongyi Metal?

At Tongyi Metal, we provide high-quality 303 stainless steel bars with superior machinability, durability, and precision. Whether you need materials for automotive, aerospace, medical, or industrial applications, we ensure consistent quality and competitive pricing.

303 stainless steel bars offer great machinability, good corrosion resistance, and durability, making them ideal for precision machining, automotive, aerospace, and more. If you need high-quality 303 stainless steel, contact Tongyi Metal for reliable solutions tailored to your needs.