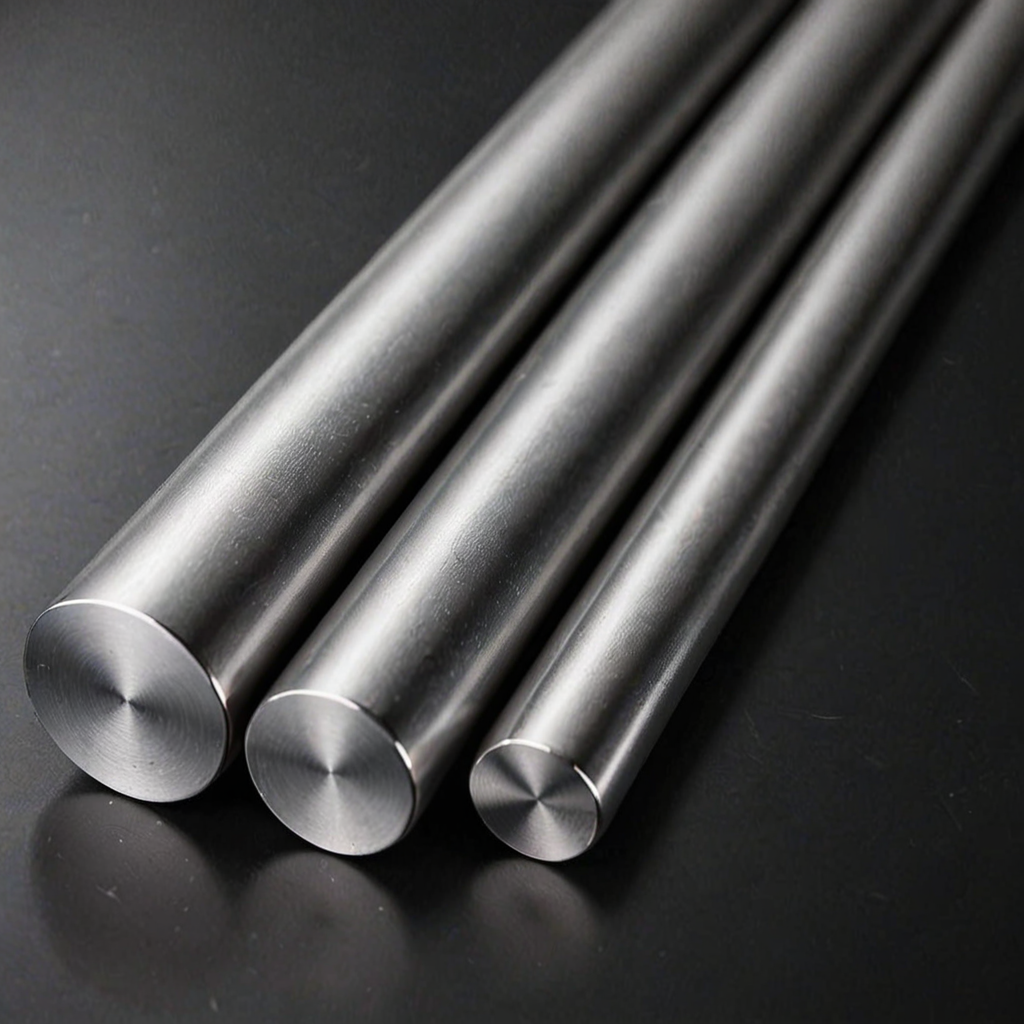

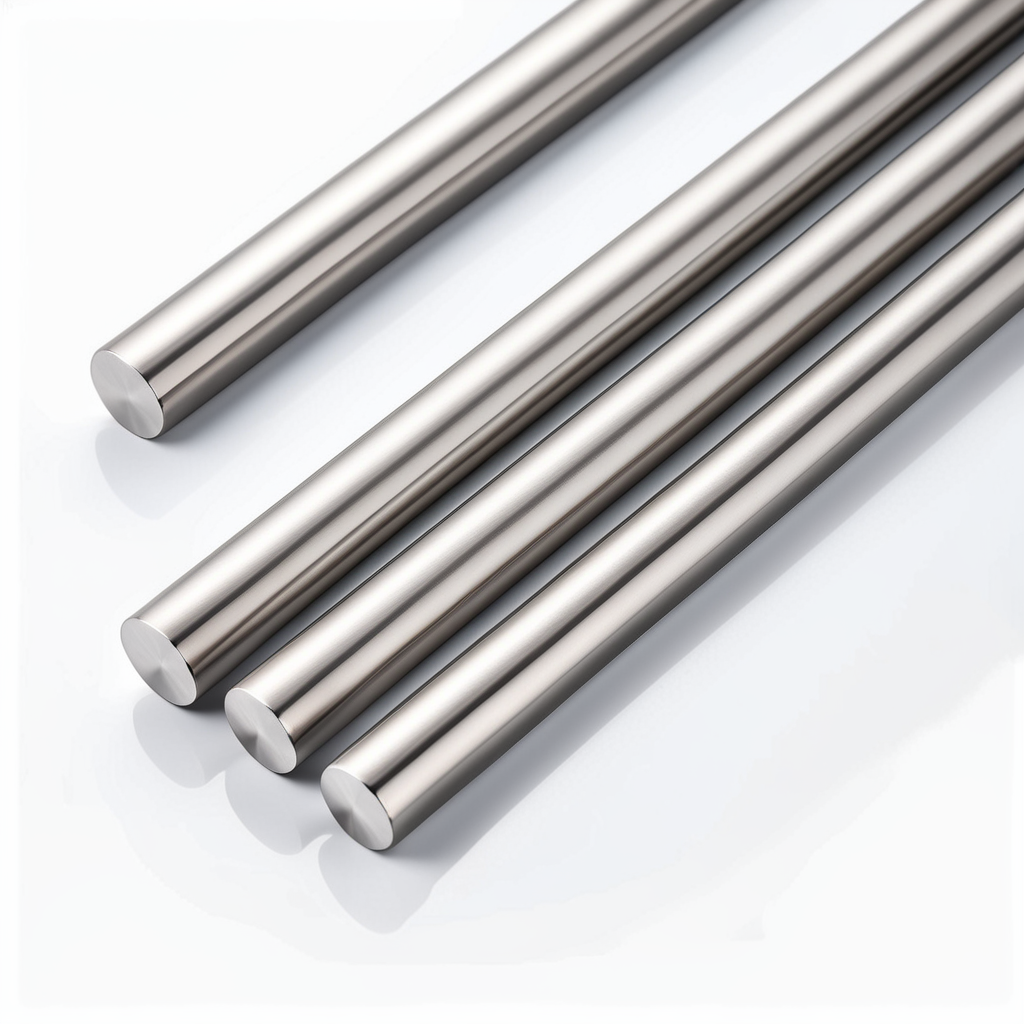

Selecting the right 303 stainless steel bar can significantly enhance machining efficiency, reduce tool wear, and improve final product quality. This article explores the key factors to consider when choosing 303 stainless steel rods, helping manufacturers make the best decision for their applications.

Key Factors in Choosing 303 Stainless Steel Bars

| Factor | Details |

|---|---|

| Diameter & Size | Choose the appropriate diameter for precision and material stability during machining. |

| Surface Finish | Smooth finishes reduce friction and improve cutting performance. |

| Tolerance & Straightness | High straightness and tight tolerances minimize machining errors. |

| Sulfur Content | Higher sulfur improves machinability but may slightly reduce corrosion resistance. |

| Hardness & Strength | Consider the required balance between hardness and flexibility for the application. |

| Supplier Quality | Reliable suppliers, like Tongyi Metal, ensure consistent quality and performance. |

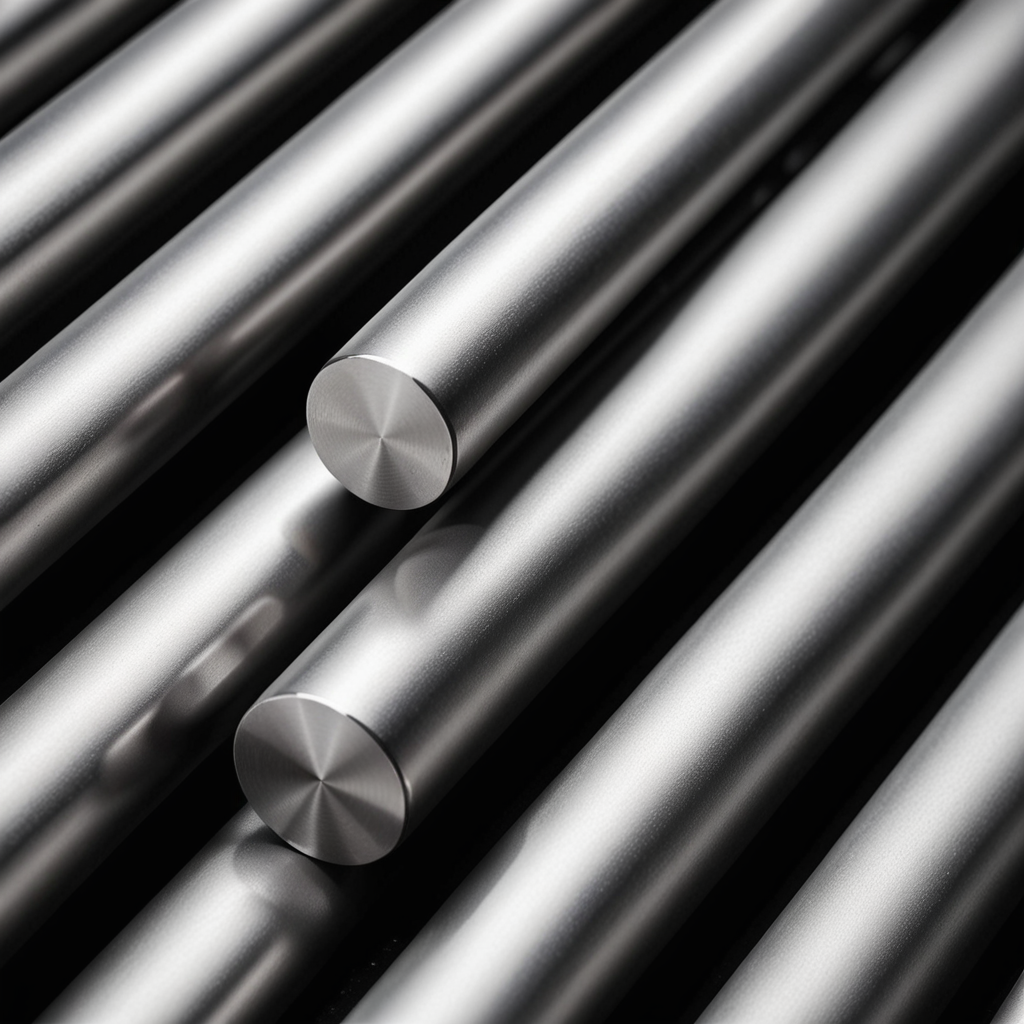

Why Surface Finish Matters

A high-quality surface finish enhances machinability by reducing cutting resistance. For precision machining, opt for polished or ground 303 stainless steel bars to minimize tool wear and improve consistency.

Tolerance and Straightness for Precision

Tight tolerances ensure uniformity, crucial for CNC machining. Straight bars prevent alignment issues and improve cutting accuracy. Tongyi Metal’s 303 stainless steel bars are produced with strict tolerance control, making them ideal for precision applications.

Machinability & Sulfur Content

303 stainless steel contains sulfur to improve machinability. However, higher sulfur content can slightly affect corrosion resistance. When selecting a 303 stainless steel rod, balance machinability and durability based on your manufacturing needs.

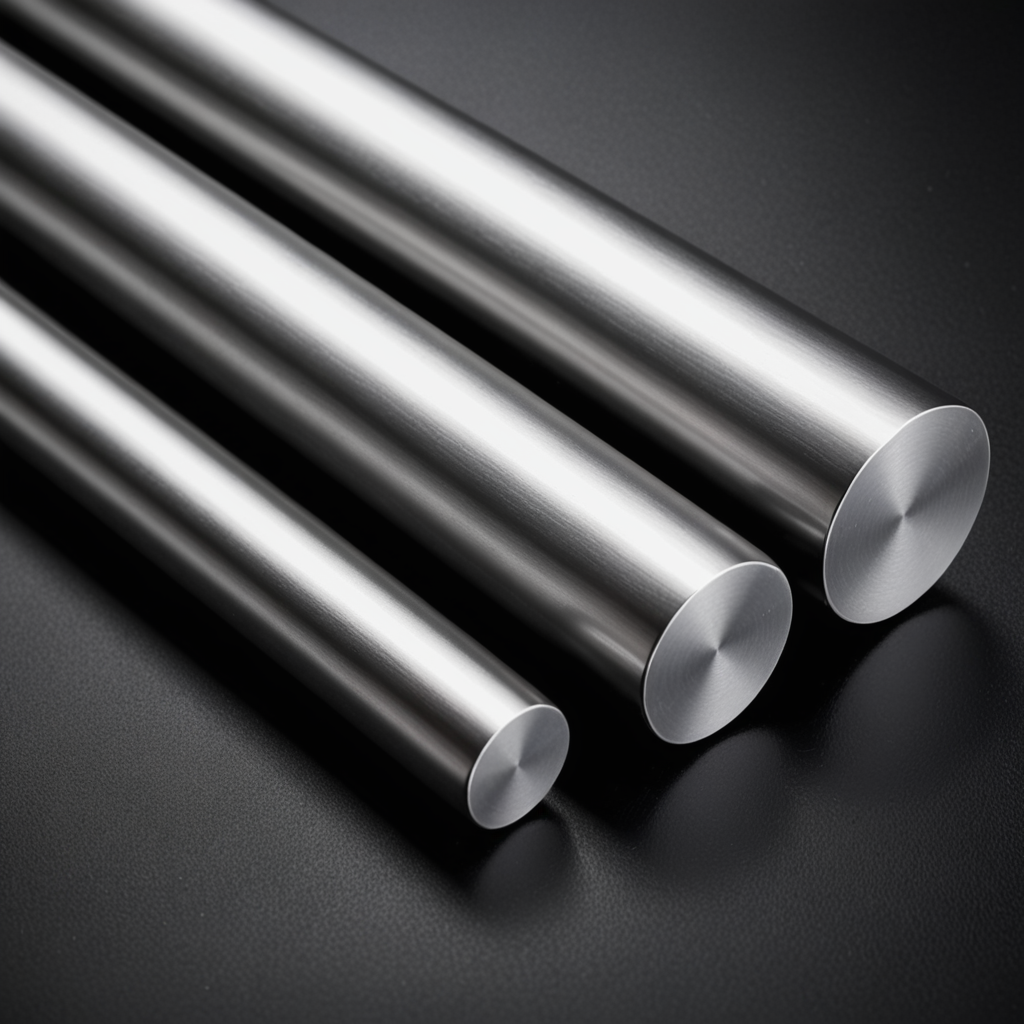

Choosing a Trusted Supplier

Reliable suppliers ensure consistent material quality. Tongyi Metal provides high-precision 303 stainless steel bars, ensuring optimal machining performance for industries like automotive, aerospace, and medical manufacturing.

Choosing the right 303 stainless steel bar involves considering size, surface finish, tolerance, sulfur content, and supplier reliability. Tongyi Metal offers premium 303 stainless steel rods designed for high machining efficiency, precision, and durability. Contact us today for expert guidance!