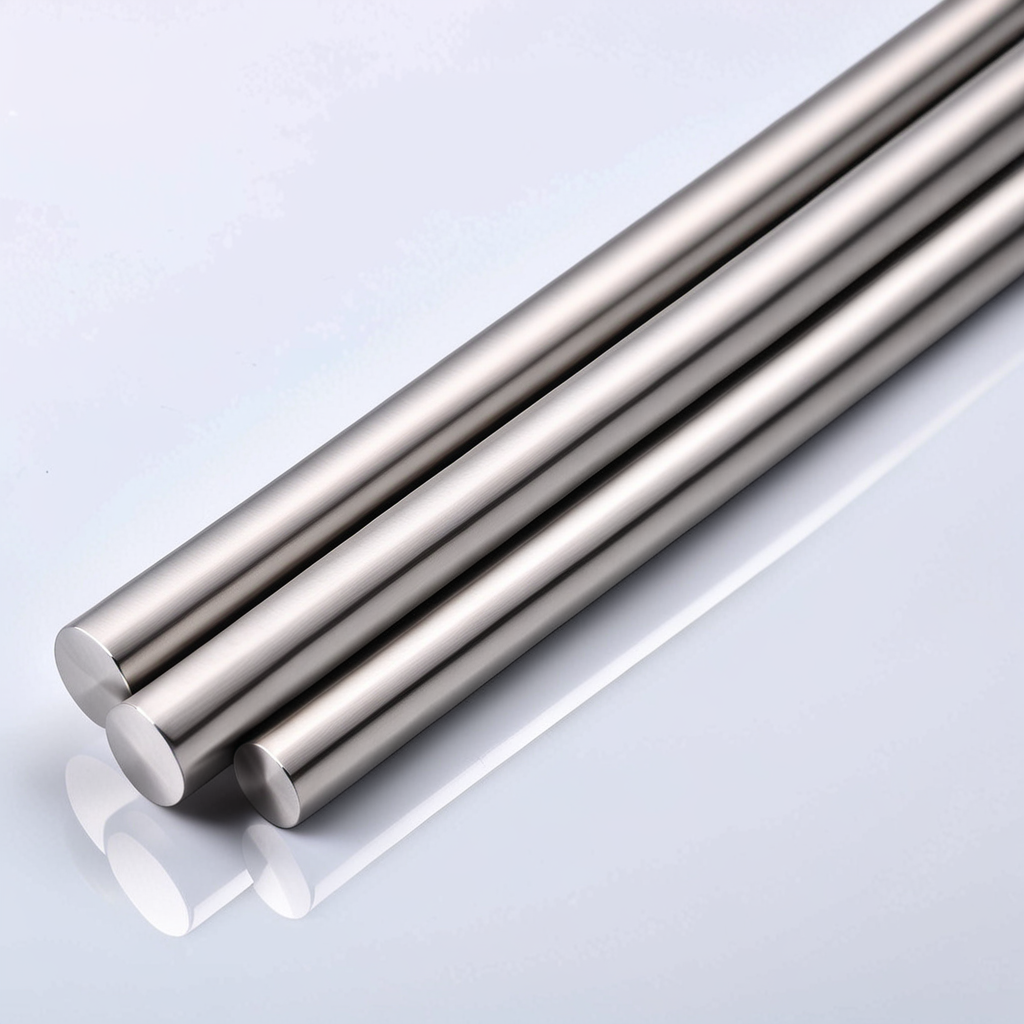

When selecting the right stainless steel bar for your project, 304 and 316 stainless steel bars are two common choices. Both play a vital role in various industrial applications, but their properties and suitable applications differ. Understanding these differences can help you make the best choice for your project. This article will explore the key differences, benefits, and applications of both types of stainless steel bars, assisting you in making an informed decision.

1. Characteristics and Applications of 304 Stainless Steel Bar

304 stainless steel bar is one of the most commonly used austenitic stainless steels, containing approximately 18% chromium and 8% nickel, providing good corrosion resistance and oxidation resistance. This makes 304 stainless steel bars suitable for use in many environments, particularly in mild and neutral conditions.

Key Features:

- Corrosion Resistance: 304 stainless steel bars perform excellently in most standard environments, making them ideal for general use.

- Machinability: 304 stainless steel bars are easy to process and weld, making them suitable for various industrial processing like cutting, bending, and forming.

- Strength and Toughness: The strength of 304 stainless steel bars is moderate, making them suitable for applications with medium loads.

Typical Applications:

304 stainless steel bars are widely used in food processing equipment, medical instruments, architectural decoration, and chemical containers. It is particularly ideal for applications requiring high corrosion resistance.

2. Characteristics and Applications of 316 Stainless Steel Bar

316 stainless steel bar, an austenitic stainless steel that contains molybdenum (Mo), offers superior corrosion resistance compared to

304 stainless steel bars. This makes 316 stainless steel bars especially suitable for harsher environments, such as those with chloride exposure or marine applications.

Key Features:

- Enhanced Corrosion Resistance: With the addition of molybdenum, 316 stainless steel bars provide superior performance in chloride or seawater environments.

- High Temperature Resistance: 316 stainless steel bars maintain their strength and stability in high-temperature environments.

- Machinability: Compared to 304 stainless steel bars, 316 stainless steel bars are more challenging to process, requiring specialized equipment.

Typical Applications:

316 stainless steel bars are widely used in marine, chemical engineering, pharmaceutical industries, and other applications where higher corrosion resistance and oxidation resistance are required, such as seawater cooling systems, wastewater treatment facilities, and chemical reactors.

3. Comparison Between 304 Stainless Steel Bar and 316 Stainless Steel Bar

When choosing between 304 stainless steel bar and 316 stainless steel bar, it’s crucial to consider the specific use environment and project requirements. Here’s a comparison of the key differences:

| Feature |

304 Stainless Steel Bar |

316 Stainless Steel Bar |

| Corrosion Resistance |

Good, suitable for standard environments |

Superior, ideal for harsh environments |

| Operating Temperature |

Medium temperature, suitable for regular industrial use |

Excellent performance in high-temperature environments |

| Machining Difficulty |

Easy to machine |

More difficult, requires specialized equipment |

| Cost |

Lower |

Higher |

| Typical Applications |

Food, medical, architectural, etc. |

Marine, chemical, pharmaceutical industries |

4. Which is Best for Your Project?

When to Choose 304 Stainless Steel Bar:

If your project involves regular environments and does not require extreme corrosion resistance, 304 stainless steel bar is an excellent choice. Its lower cost and good machinability make it the preferred option for many industrial applications, particularly in household appliances, food equipment, and architectural decoration.

When to Choose 316 Stainless Steel Bar:

If your project requires enhanced corrosion resistance, especially in seawater, chemical exposure, or high-temperature environments, 316 stainless steel bar is the best option. It is widely used in marine equipment, chemical reactors, and pharmaceutical industries, where ensuring material longevity and stability in extreme conditions is essential.

5. Conclusion

Choosing between 304 stainless steel bar and 316 stainless steel bar depends primarily on the corrosion resistance, machinability, and operating environment required for your project. 304 stainless steel bar is ideal for general industrial and everyday applications, while

316 stainless steel bar is the better choice for extreme environments.

If you need more technical support or pricing information regarding stainless steel bars, feel free to contact us. We offer professional advice and solutions to help you make the most informed decision when selecting stainless steel bars for your project.