- No. 51 Fuyang Road, Dalang Town, Dongguan City, Guangdong Province

- info@tongyimetal.com

- +8613929471444

| Alloy Designation | Main Component(%) | |||||||||||

| C | Si | Mu | P | S | Ni | Cr | Mo | Cu | Pb | N | more | |

| SUS303 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.20 | ≥0.15 | 8.00~10.00 | 17.00~19.00 | ≤0.60 | – | – | – | |

| SUS303CU | ≤0.15 | ≤1.00 | ≤3.00 | ≤0.20 | ≥0.15 | 8.00~10.00 | 17.00~19.00 | ≤0.60 | 1.50~3.50 | – | – | |

| SUS304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 8.00~10.50 | 18.00~20.00 | – | – | – | – | |

| SUS304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 9.00~13.00 | 18.00~20.00 | – | – | – | – | |

| 304FL | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 8.00~10.50 | 18.00~20.00 | – | – | – | – | |

| SUS310S | ≤0.08 | ≤1.50 | ≤2.00 | ≤0.045 | ≤0.030 | 19.00~22.00 | 24.00~26.00 | – | – | – | – | |

| SUS316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 | – | – | – | |

| SUS316L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 12.00~15.00 | 16.00~18.00 | 2.00~3.00 | – | – | – | |

| SUS316F | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≥0.10 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 | – | – | – | |

| SUS316Ti | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 | ≤0.1 | Ti:5×(C+N) ~ 0.70 | ||

| SUS321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 9.00~13.00 | 17.00~19.00 | – | – | – | – | |

| Alloy Designation | Main Component(%) | ||||||||||||||

| Main Component | Impurities(≤) | ||||||||||||||

| Ti | Al | Sn | Mo | Pd | Ni | Si | B | Fe | C | N | H | O | Other | ||

| Only | Total | ||||||||||||||

| TA1 | Margin | – | – | – | – | – | – | – | 0.2 | 0.08 | 0.03 | 0.015 | 0.18 | 0.1 | 0.4 |

| TA2 | Margin | – | – | – | – | – | – | – | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | 0.1 | 0.4 |

| TA3 | Margin | – | – | – | – | – | – | – | 0.3 | 0.08 | 0.05 | 0.015 | 0.35 | 0.1 | 0.4 |

| TA4 | Margin | – | – | – | – | – | – | – | 0.5 | 0.08 | 0.05 | 0.015 | 0.4 | 0.1 | 0.4 |

| TA5 | Margin | 3.3~4.7 | – | – | – | – | – | 0.005 | 0.3 | 0.08 | 0.04 | 0.015 | 0.15 | 0.1 | 0.4 |

| TA6 | Margin | 4.0~5.5 | – | – | – | – | – | – | 0.3 | 0.08 | 0.05 | 0.015 | 0.15 | 0.1 | 0.4 |

| TA7 | Margin | 4.0~6.0 | 2.0~3.0 | – | – | – | – | – | 0.5 | 0.08 | 0.05 | 0.015 | 0.2 | 0.1 | 0.4 |

| TA8 | Margin | – | – | – | 0.04~0.08 | – | – | – | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | 0.1 | 0.4 |

| TA9 | Margin | – | – | – | 0.12~0.25 | – | – | – | 0.25 | 0.08 | 0.03 | 0.015 | 0.2 | 0.1 | 0.4 |

| TA10 | Margin | – | – | 0.2~0.4 | – | 0.6~0.9 | – | – | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | 0.1 | 0.4 |

| Alloy Designation | Main Component(%) | |||||

| C | Si | Mn | P | S | more | |

| 1006 | Max 0.08 | 0.015~0.035 | 0.25~0.40 | ≤ 0.030 | ≤0.035 | – |

| 1008 | Max 0.10 | 0.015~0.035 | 0.30~0.50 | ≤ 0.030 | ≤0.035 | – |

| 1010 | 0.08~0.13 | 0.015~0.035 | 0.30~0.60 | ≤ 0.030 | ≤0.035 | – |

| 1015 | 0.13~0.18 | 0.015~0.035 | 0.30~0.60 | ≤ 0.030 | ≤0.035 | – |

| 1020 | 0.18~0.23 | 0.015~0.035 | 0.30~0.60 | ≤ 0.030 | ≤0.035 | – |

| 1021 | 0.18~0.23 | 0.015~0.035 | 0.60~0.90 | ≤ 0.030 | ≤0.035 | – |

| 1022 | 0.18~0.23 | 0.015~0.035 | 0.70~1.00 | ≤ 0.030 | ≤0.035 | – |

| 1025 | 0.22~0.28 | 0.015~0.035 | 0.30~0.60 | ≤ 0.030 | ≤0.035 | – |

| 1030 | 0.27~0.33 | 0.015~0.035 | 0.60~0.90 | ≤ 0.030 | ≤0.035 | – |

| 1035 | 0.32~0.38 | 0.015~0.035 | 0.60~0.90 | ≤ 0.030 | ≤0.035 | – |

| 1045 | 0.42~0.48 | 0.015~0.035 | 0.60~0.90 | ≤ 0.030 | ≤0.035 | – |

| 1050 | 0.47~0.53 | 0.015~0.035 | 0.60~0.90 | ≤ 0.030 | ≤0.035 | – |

| 1055 | 0.52~0.58 | 0.015~0.035 | 0.60~0.90 | ≤ 0.030 | ≤0.035 | – |

| 1060 | 0.55~0.65 | 0.015~0.035 | 0.60~0.90 | ≤ 0.030 | ≤0.035 | – |

| NO. | JIS | Main Component(%) | ||||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | Pb | N | ||

| 12L14 | SUM24L | ≦0.15 | – | 0.85~1.15 | 0.04~0.09 | 0.26~0.35 | – | – | – | – | 0.10~0.35 | – |

| 1215 | SUM23 | ≦0.09 | – | 0.75~1.05 | 0.04~0.09 | 0.26~0.35 | – | – | – | – | – | – |

| 1215MS | – | ≦0.09 | – | 1.10~1.60 | 0.04~0.09 | 0.33~0.42 | – | – | – | – | – | – |

| 1141 | SUM42 | 0.37~0.45 | – | 1.35~1.65 | ≦0.04 | 0.08~0.13 | – | – | – | – | – | – |

| 1144 | SUM43 | 0.40~0.48 | – | 1.35~1.65 | ≦0.04 | 0.24~0.33 | – | – | – | – | – | – |

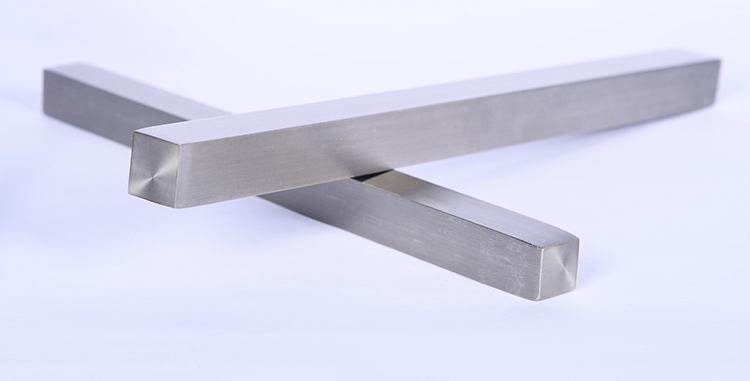

Tongyi metal stainless steel square bar features strict dimensional tolerances and excellent surface quality, usually produced through cold drawing or precision grinding processes. It is widely used in the fields of machining, automation equipment, precision instruments, and architectural decoration. Due to its outstanding precision and stability, it has become an indispensable material in high-end manufacturing and engineering structures.

The outer diameter tolerance is uniformly controlled within ± 0.02 mm to ensure the consistency of the size of each square rod, avoid errors or clearance problems during assembly, and thus improve assembly efficiency. Meanwhile, strict tolerance control can ensure its long-term stable operation in high-precision mechanical assembly and automation equipment.

The surface roughness can usually reach Ra0.6. After fine processes such as cold drawing, polishing, acid washing, etc., not only does the surface become smoother and smoother, but it also effectively removes the oxide layer, small burrs, and other defects on the surface. Widely used in industrial processing fields with strict surface requirements.

High precision stainless steel square bars have good tensile strength and compressive strength, and can withstand external forces that may be encountered during assembly without deformation or fracture. At the same time, it should also have good impact resistance to avoid fatigue failure under dynamic loads.

Our company’s products are suitable for various fields such as digital products, electrical appliances, medical, office equipment, power clocks, electromechanical, robotics, automotive, electronics, etc. We strive to create high-quality products in the industry.

Guangdong tongyi metal technology co., ltd. Is a leading brand specializing in the production of precision special steel. We offer a wide range of standard products and excel in providing custom steel grades, shape customization, and bulk orders to meet the stringent requirements of precision hardware parts processing. driving technological innovation and delivering high-quality metal materials and solutions to our clients.

We have 168 imported high-precision equipment and more than 30 core technicians.

Up to 30000 tons of metal materials can be produced annually

We collaborate with over 10000 strategic partners globally

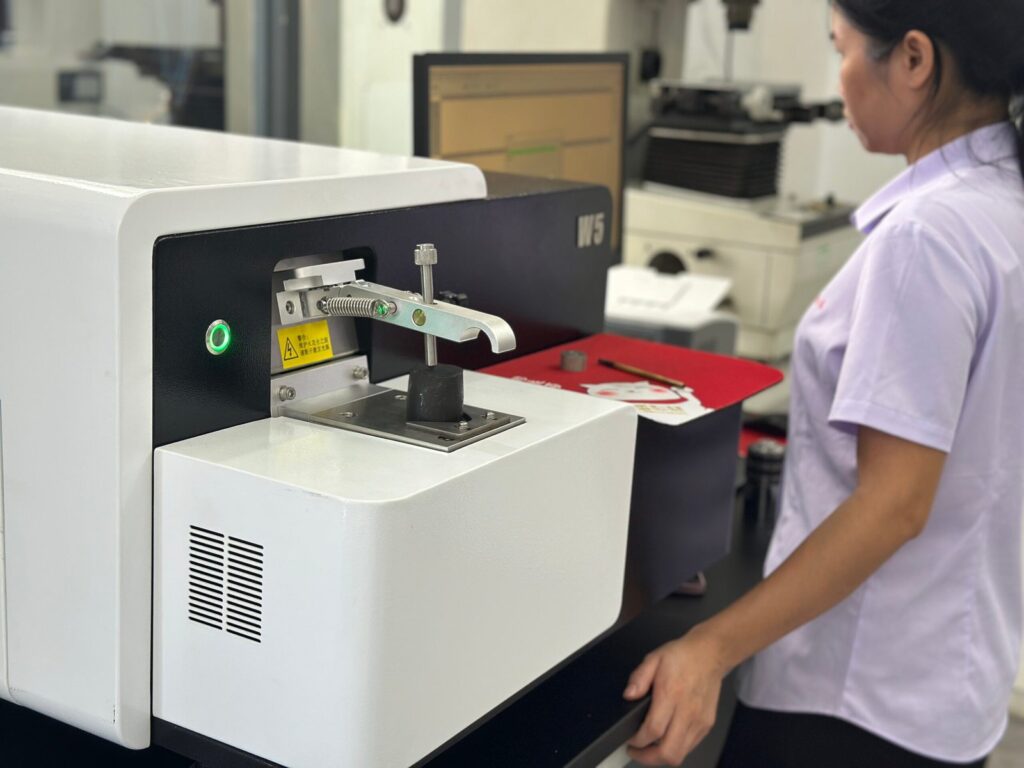

The company has more than 100 production equipment imported from japan and 38 core technicians. Strictly implement iso9001 management system in the production process, import high-precision testing equipment can provide accurate data support to win customer trust and support with high quality and fast delivery.

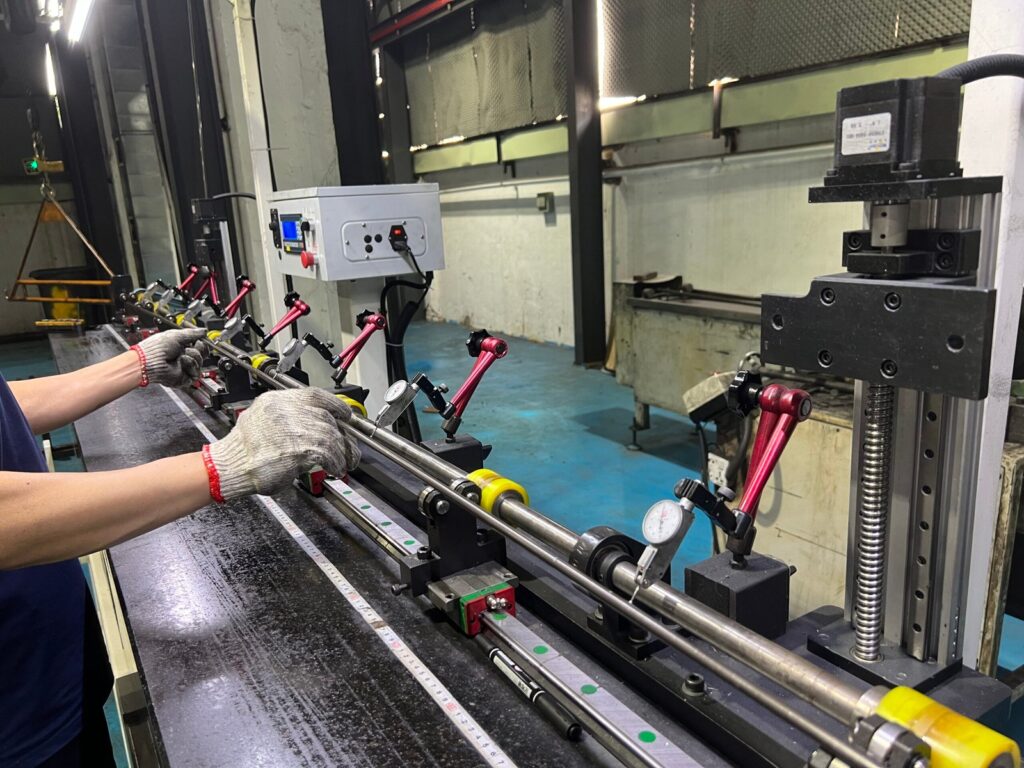

The same metal has 68 sets of measuring equipment imported from Japan, such as Mitoyo micrometer, straightness test, hardness tester, spectrometer, magnetic detector, etc. The outer diameter accuracy of the material is measured once every 5 minutes, and the quality is all qualified before packaging and shipping.

The same metal has 15 years of stainless steel rod/wire material research and development, design, production experience, foreign large strength manufacturers. Customized matching material solutions according to customer needs in various industries.

offers clear and concise answers to the most frequently asked questions about our stainless steel bars, ensuring you get the information you need quickly and efficiently.

We offer a variety of stainless steel, titanium alloy, quenched and tempered steel bars and wires, including 303, 304, 316, 410, and more. We can also customize the composition according to your requirements.

Yes, we can customize the length of stainless steel bars according to the specific requirements of our customers, reducing material waste and lowering costs.

Our stainless steel bars are widely used in various industries, including construction, automotive, medical devices, food processing, and aerospace.

We offer a variety of surface treatment options, including polishing, brushing, pickling, and mirror finishing, to meet different application needs.

We adhere to the ISO9001 quality management system, conducting strict quality control at every stage from raw material procurement to the production process, and we also offer third-party inspection services.

Materials, appearance, dimensions, straightness, smoothness, etc. can be customized according to needs

Materials, appearance, dimensions, straightness, smoothness, etc. can be customized according to needs