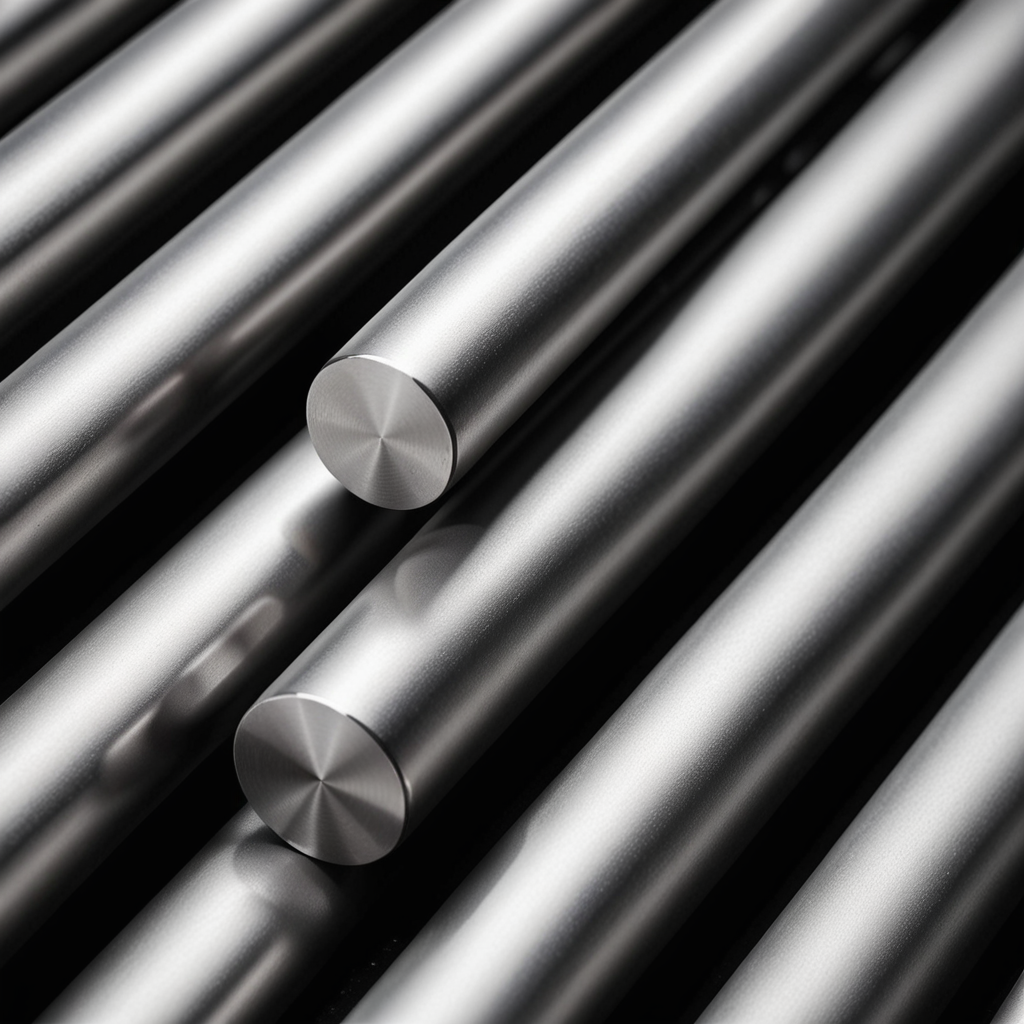

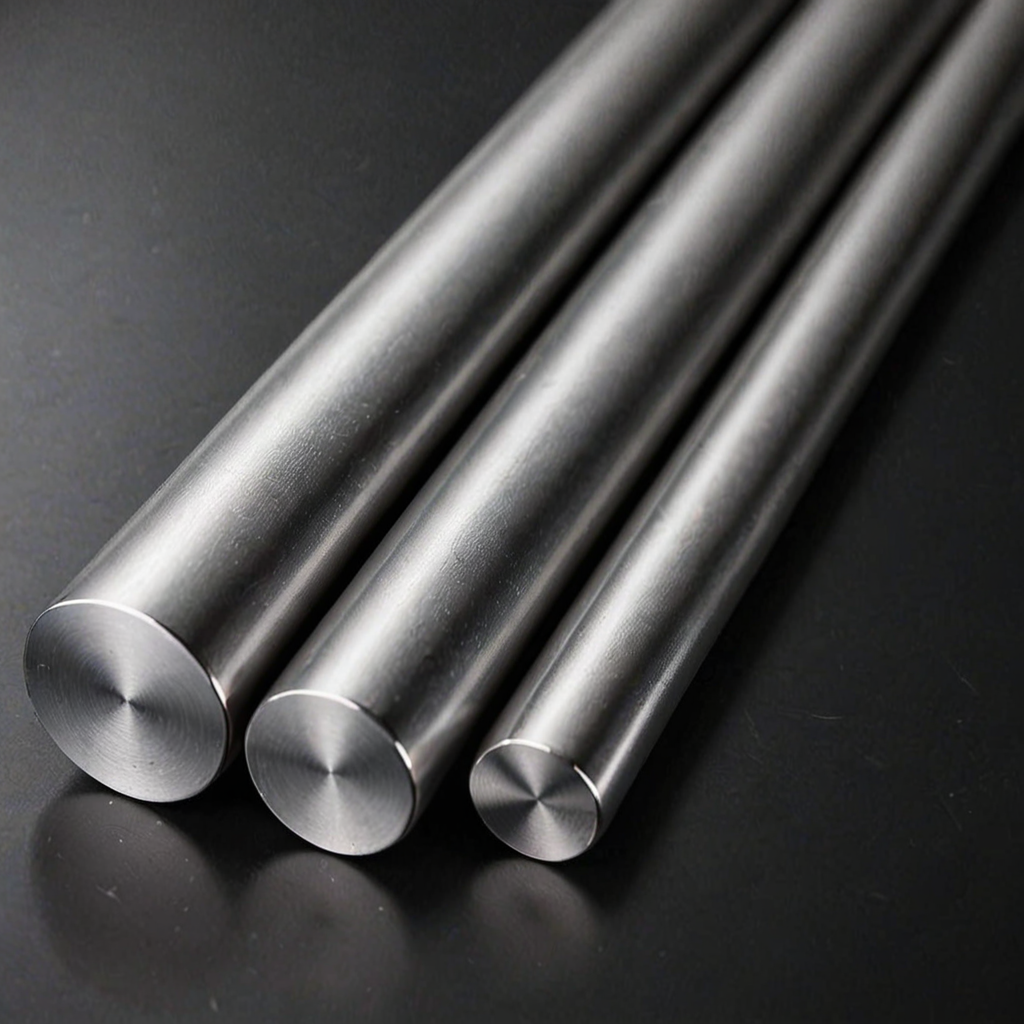

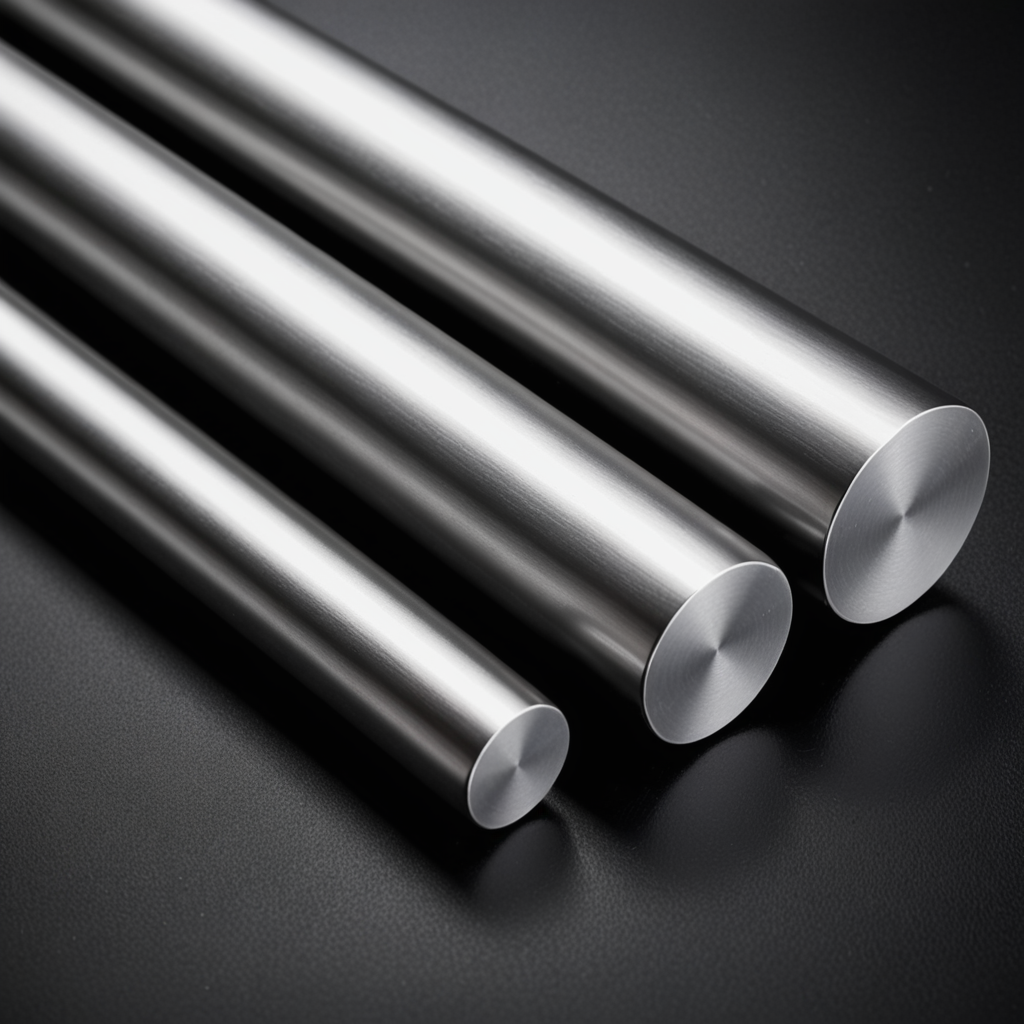

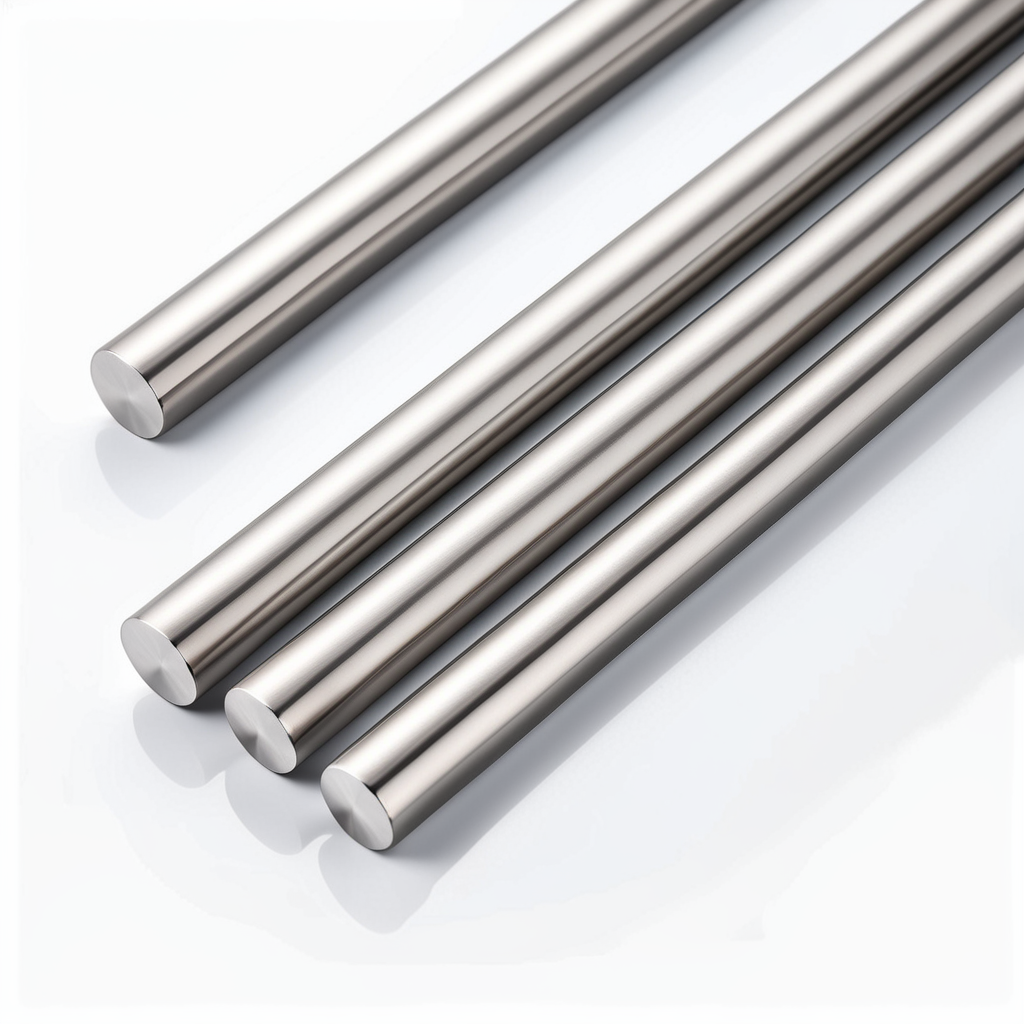

Precision parts manufacturing demands materials that offer excellent machinability, durability, and corrosion resistance. 303 stainless steel bars meet these requirements, making them a preferred choice in various industries. This article explores how 303 stainless steel bars are applied in precision machining and why they are ideal for such applications.

Why Choose 303 Stainless Steel Bars for Precision Machining?

303 stainless steel bars contain sulfur, which enhances their machinability, reducing tool wear and improving efficiency. Their corrosion resistance and excellent surface finish make them ideal for precision parts used in demanding environments.

Key Properties of 303 Stainless Steel Bars

| Property | Benefit in Precision Manufacturing |

|---|---|

| Excellent Machinability | Reduces tool wear and improves machining speed. |

| Corrosion Resistance | Enhances durability in harsh environments. |

| High Surface Finish | Minimizes post-processing and improves aesthetics. |

| Good Mechanical Strength | Ensures reliability in high-stress applications. |

Common Applications of 303 Stainless Steel Bars in Precision Parts

1. Aerospace Components

303 stainless steel bars are widely used in aerospace for manufacturing precision fasteners, fittings, and shafts. Their machinability ensures tight tolerances and smooth finishes, crucial for aerospace applications.

2. Automotive Industry

The automotive sector requires components with high wear resistance and precision. 303 stainless steel bars are commonly used for producing gears, shafts, and connectors, where accurate dimensions and a polished surface are essential.

3. Medical Equipment

Medical instruments require high precision and corrosion resistance. 303 stainless steel is commonly used in surgical tools and dental instruments due to its excellent surface finish and biocompatibility.

4. Electronics & Electrical Components

Precision connectors and electronic parts demand materials that provide accurate shaping and conductivity. 303 stainless steel ensures tight tolerances, making it an excellent choice for electronic applications.

5. Industrial Machinery & Automation

303 stainless steel bars are used in precision mechanical components, such as bearings, bushings, and custom fasteners. Their wear resistance and strength make them ideal for automated manufacturing systems.

Advantages of Using 303 Stainless Steel Bars in Precision Parts

- High machining efficiency: Faster production with less tool wear.

- Consistent quality: Ensures uniform dimensions and surface finish.

- Cost-effectiveness: Reduces manufacturing costs by minimizing tool replacement and material waste.

- Durability: Provides long-lasting performance in high-precision applications.

303 stainless steel bars play a vital role in precision parts manufacturing, offering excellent machinability, corrosion resistance, and a high-quality surface finish. Industries such as aerospace, automotive, medical, and electronics benefit significantly from their properties. If you require high-quality stainless steel bars for precision machining, Tongyi Metal provides reliable and cost-effective solutions tailored to your needs.