The drone motor shaft is a critical component with extremely high precision requirements, as it plays a key role in ensuring the performance and stability of drones. As a manufacturer specializing in customized high-precision stainless steel bars, we understand that the quality of these bars is essential for the production of durable and reliable motor shafts.

Our stainless steel bars offer processing accuracy of up to 0.004mm, ensuring excellent smoothness and straightness. This precision not only enhances the surface quality of the motor shaft but also optimizes the bearing assembly, contributing to greater stability and extending the shaft’s service life.

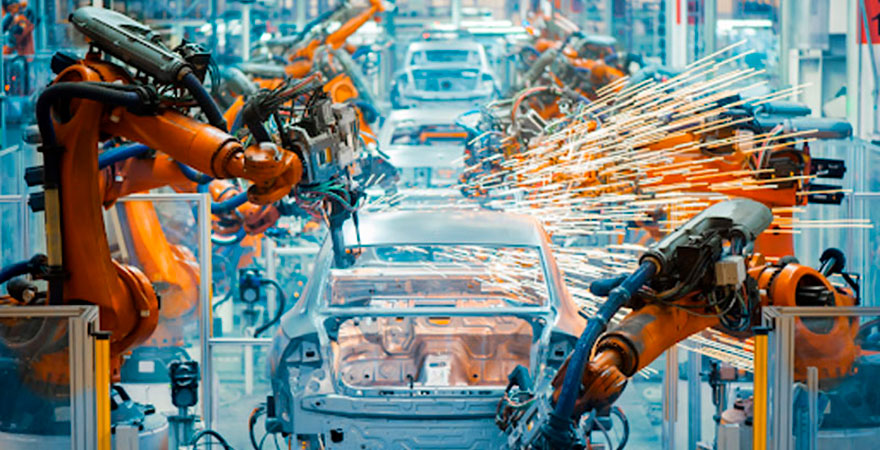

Drones: A Fast-Growing Industry

Drones have rapidly become an essential technology, used across various industries, including:

- Industry

- Agriculture

- Military

- Environmental protection

- Disaster relief

For example, drones equipped with camera devices are widely used in aerial photography, enabling large-scale observations from the sky. Similarly, drones have made significant contributions in power inspection, testing, and even disaster relief, where they play an irreplaceable role.

Materials Used in Drone Motor Shafts

Drone motor shafts are typically made from materials such as imported SK7, 420 stainless steel, or powder metallurgy. The choice of material depends on the shaft’s structure, torque requirements, and expected lifespan. These factors help ensure the shaft offers excellent wear resistance, making it less prone to deformation and fracture.

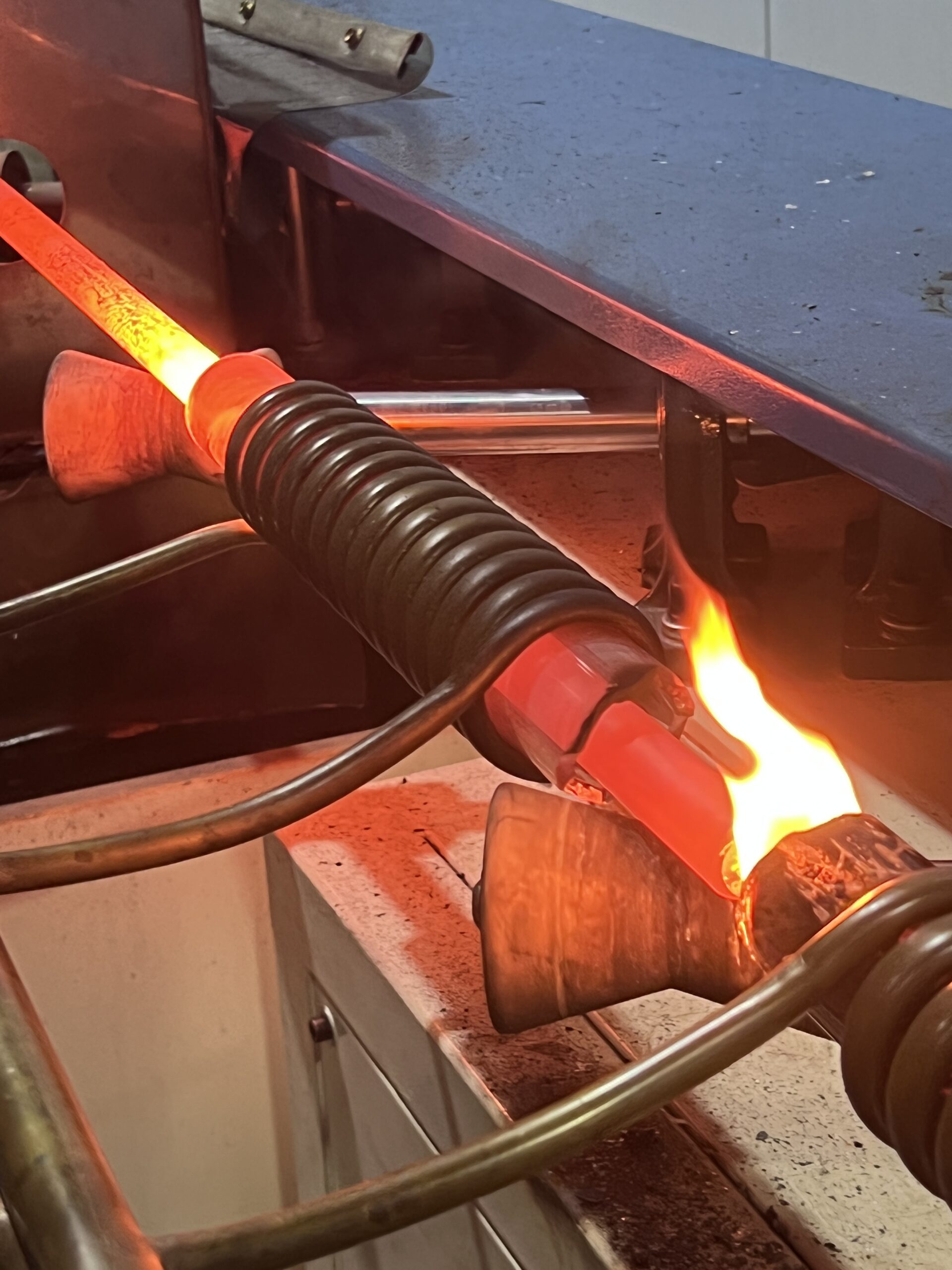

Enhancing Durability with Heat Treatment

To prevent issues like deformation and fracture, the hardness of drone shafts is typically improved through heat treatment processes. This involves heating, insulation, and cooling, which help to strengthen the shaft and improve its performance under stress.

Rust Prevention and Corrosion Resistance

When used outdoors, shafts are exposed to elements that can cause rust or corrosion. To combat this, salt spray testing is commonly used to improve the shaft’s anti-corrosion properties and extend its service life. For example, the salt spray test time for a laptop spindle can exceed 8-12 hours, though this varies depending on the material used.